NATIONAL

TRANSPORTATION

SAFETY BOARD

WASHINGTON, D.C. 20594

AIRCRAFT ACCIDENT REPORT

PB2001-910401

NTSB/AAR-01/01

DCA91MA023

Uncontrolled Descent and Collision With Terrain

United Airlines Flight 585

Boeing 737-200, N999UA

4 Miles South of Colorado Springs

Municipal Airport

Colorado Springs, Colorado

March 3, 1991

5498C

this page intentionally left blank

Aircraft Accident Report

Uncontrolled Descent and Collision With Terrain

United Airlines Flight 585

Boeing 737-200, N999UA

4 Miles South of Colorado Springs

Municipal Airport

Colorado Springs, Colorado

March 3, 1991

NTSB/AAR-01/01

PB2001-910401 National Transportation Safety Board

Notation 5498C 490 L’Enfant Plaza, S.W.

Adopted March 27, 2001 Washington, D.C. 20594

E

P

L

U

R

I

B

U

S

U

N

U

M

N

A

T

I

O

N

A

L

T

R

A

S

P

O

R

T

A

T

I

O

N

B

O

A

R

D

S

A

F

E

T

Y

N

National Transportation Safety Board. 2001. Uncontrolled Descent and Collision With Terrain,

United Airlines Flight 585, Boeing 737-200, N999UA, 4 Miles South of Colorado Springs Municipal

Airport, Colorado, Springs, Colorado, March 3, 1991. Aircraft Accident Report NTSB/AAR-01/01.

Washington, DC.

Abstract: This amended report explains the accident involving United Airlines flight 585, a

Boeing 737-200, which entered an uncontrolled descent and impacted terrain 4 miles south of Colorado

Springs Municipal Airport, Colorado Springs, Colorado, on March 3, 1991. Safety issues discussed in the

report are the potential meterological hazards to airplanes in the area of Colorado Springs; 737 rudder

malfunctions, including rudder reversals; and the design of the main rudder power control unit servo valve.

The National Transportation Safety Board is an independent Federal agency dedicated to promoting aviation, railroad, highway, marine,

pipeline, and hazardous materials safety. Established in 1967, the agency is mandated by Congress through the Independent Safety Board

Act of 1974 to investigate transportation accidents, determine the probable causes of the accidents, issue safety recommendations, study

transportation safety issues, and evaluate the safety effectiveness of government agencies involved in transportation. The Safety Board

makes public its actions and decisions through accident reports, safety studies, special investigation reports, safety recommendations, and

statistical reviews.

Recent publications are available in their entirety on the Web at <http://www.ntsb.gov>. Other information about available publications also

may be obtained from the Web site or by contacting:

National Transportation Safety Board

Public Inquiries Section, RE-51

490 L'Enfant Plaza, S.W.

Washington, D.C. 20594

(800) 877-6799 or (202) 314-6551

Safety Board publications may be purchased, by individual copy or by subscription, from the National Technical Information Service. To

purchase this publication, order report number PB2001-910401 from:

National Technical Information Service

5285 Port Royal Road

Springfield, Virginia 22161

(800) 553-6847 or (703) 605-6000

The Independent Safety Board Act, as codified at 49 U.S.C. Section 1154(b), precludes the admission into evidence or use of Board reports

related to an incident or accident in a civil action for damages resulting from a matter mentioned in the report.

iii Aircraft Accident Report

Contents

Introduction to Amended Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Executive Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1. Factual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 History of Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Injuries to Persons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Damage to Aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Other Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Personnel Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.1 The Captain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.2 The First Officer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.3 Flight Crew Activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.4 Air Traffic Control Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Airplane Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6.2 Maintenance History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6.3 Boeing 737 Hydraulic System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6.4 Boeing 737 Flight Control Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6.4.1 Rudder Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6.4.1.1 Main Rudder PCU and Servo Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7 Meteorological Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.7.1 Observations and Forecasts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.7.2 Topics from Meteorological Meeting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.7.3 Witness Information and Satellite Data on Vortices . . . . . . . . . . . . . . . . . . . . . . . . 34

1.7.4 Previous Accidents/Incidents Attributed to Vortices. . . . . . . . . . . . . . . . . . . . . . . . 35

1.7.5 Review of Information Obtained from A.J. Bedard, Jr., NOAA. . . . . . . . . . . . . . . 36

1.8 Aids To Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.9 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.10 Aerodrome Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.10.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.10.2 Weather Related Accidents/Incident Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.11 Flight Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.12 Wreckage and Impact Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.12.1 Engine Mount Examinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.12.2 Examination of Roll and Pitch Flight Controls Components

and Other Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.12.2.1 Hydraulic System A and B Pressure Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.12.2.2 Roll Control Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.12.2.3 Pitch Control Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.12.3 Examination of Yaw Control Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.12.3.1 System Main Rudder Power Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Contents iv Aircraft Accident Report

1.12.3.2 Standby Rudder Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1.13 Medical And Pathological Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1.14 Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.15 Survival Aspects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.16 Tests and Research . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.16.1 Recorded Radar Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.16.2 Modeling and Simulations of Atmospheric Disturbances

and Airplane Flight Dynamics Conducted During the Initial

Investigation (1991/1992). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.16.2.1 Modeling of Atmospheric Disturbances (1991/1992): NCAR

Weather Study. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.16.2.2 Safety Board Simulations (1991/1992) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.16.2.3 Boeing Simulations (1991/1992). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.16.3 Detail Examination and Tests of Standby Rudder Actuator

Input Shaft and Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.16.3.1 Additional Standby System Actuator Binding/Jam Tests . . . . . . . . . . . . . . . . . . 66

1.16.4 Other Documented Rudder Control Incidents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1.16.5 Additional Examination and Testing of 737 Flight Control

Systems/Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

1.16.5.1 Detailed Examinations of Main Rudder PCU Servo Valves . . . . . . . . . . . . . . . . 72

1.16.5.2 PCU Servo Valve Chip Shear Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1.16.5.3 PCU Thermal Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.16.5.3.1 Baseline Test Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.16.5.3.2 Simulated Hydraulic System Failure Condition . . . . . . . . . . . . . . . . . . . . . . 76

1.16.5.3.3 Extreme Temperature Differential Test Condition . . . . . . . . . . . . . . . . . . . . 76

1.16.5.3.4 Additional Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1.16.5.4 Rudder Actuator Reversals During Servo Valve

Secondary Slide Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

1.16.5.5 Ground Demonstration of Rudder PCU Servo Valve Jam. . . . . . . . . . . . . . . . . . 83

1.16.6 Flight Performance Simulation Studies Conducted During

the USAir Flight 427 Investigation (1994-1999) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

1.16.6.1 United Flight 585 Simulation Studies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1.17 Organizational and Management Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.17.1 United Airlines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.17.1.1 United Airlines Office of Flight Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1.17.1.2 United Airlines Windshear and Irregular Procedures . . . . . . . . . . . . . . . . . . . . 104

1.18 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

1.18.1 Study of Pilots’ (USAir Flight 427 and United Flight 585)

Speech, Breathing, and Other CVR-recorded Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1.18.2 Comparison of Engine Sound Signatures From the United

Flight 585 CVR and a CVR From 737-200 Flight Tests . . . . . . . . . . . . . . . . . . . . . . . . 107

1.18.3 Ergonomics—Study of Maximum Pilot Rudder Pedal Force . . . . . . . . . . . . . . . . 108

1.18.3.1 United Flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

1.18.4 Conclusions Adopted in the USAir Flight 427 Report . . . . . . . . . . . . . . . . . . . . . 110

1.18.4.1 Findings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1.18.4.2 Probable Cause. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2. Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.2 Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Contents v Aircraft Accident Report

2.3 Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2.4 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2.4.1 Hydraulic Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.4.2 Flight Control Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

2.5 Environmental Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2.5.1 General Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2.5.2 Characteristics of Horizontal Axis Vortex (Rotor) . . . . . . . . . . . . . . . . . . . . . . . . 125

2.5.3 Flight Simulations with Atmospheric Disturbances . . . . . . . . . . . . . . . . . . . . . . . 128

2.6 United Flight 585 Upset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.6.1 Computer Simulation Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.6.2 Human Performance Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2.7 Rudder System Jam Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

2.8 Flight Data Recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

3. Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.1 Findings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

3.2 Probable Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4. Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

5. Appendixes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A: Investigation and Hearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

B: Personnel Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

C: Airplane Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

D: Cockpit Voice Recorder Transcript . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

E: NCAR Weather Study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

F: Review of Literature and Correspondence Related to Severe

Weather Phenomena . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

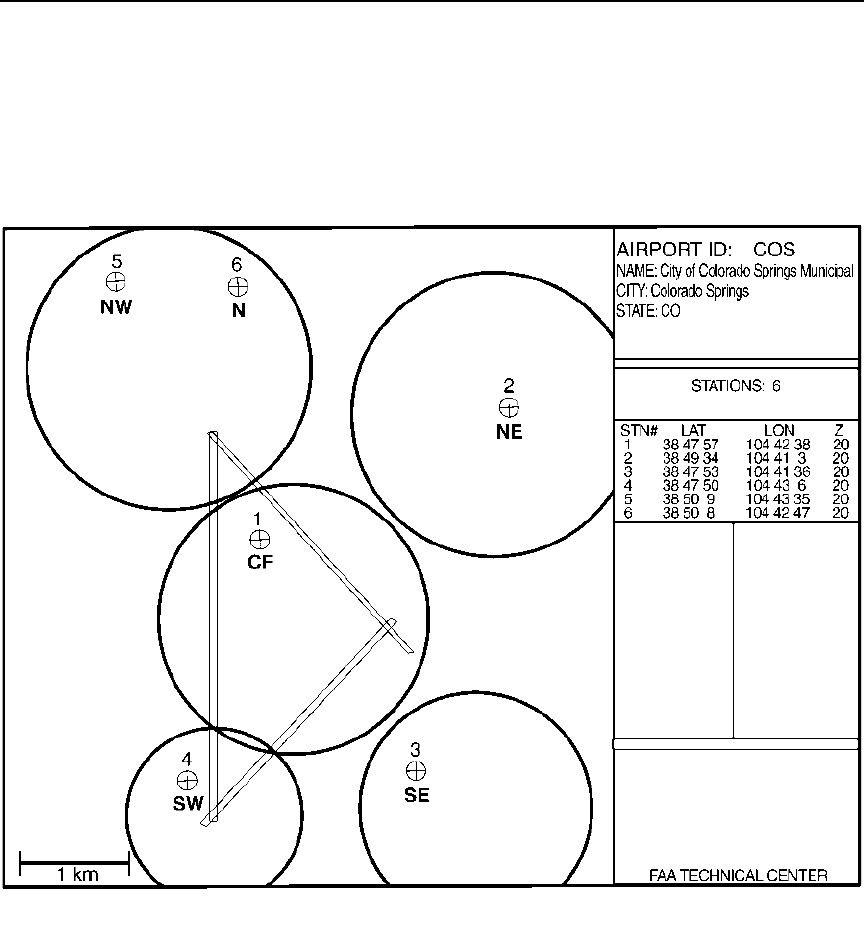

G: LLWAS Sensors and Plots of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

vi Aircraft Accident Report

Figures

1. Boeing 737-200 hydraulic system panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2. Three axes of motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Boeing 737 flight control surface locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. Boeing 737 rudder system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4a. Detailed view of 737 aft rudder system controls and linkages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5. Boeing 737 main rudder PCU.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Boeing 737 main rudder PCU schematic and installation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7. Boeing 737 main rudder PCU servo valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8. Types of airflow over ridges: (a) laminar streaming; (b) standing

eddy streaming; (c) wave streaming; and (d and e) rotor streaming.

Dashed line on left indicates vertical profile of horizontal wind speed.. . . . . . . . . . . . . . . . . . . . . . . 30

9. Ground track with selected CVR data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10. Profile view of flightpath with selected CVR data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11. Standby rudder actuator.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12. Normal operation of the 737 PCU servo valve with slides in the

neutral position (no jam). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

13. Normal operation of the 737 PCU servo valve with slides in the

extend command position (no jam). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

14. PCU servo valve intended operation with the secondary slide

jammed to the servo valve housing and primary slide opposing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

15. PCU servo valve with the secondary slide jammed to the servo

valve housing and the primary slide in the overtravel condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

16. Pilot rudder pedal force positions for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16a. Rudder surface positions for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16b. Control wheel positions for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

16c. Heading data for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figures vii Aircraft Accident Report

16d. Normal load factor data for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16e. Pitch angle data for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16f. Bank angle data for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

16g. Roll rate for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

16h. Yaw rate for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

16i. Wind direction for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

16j. Horizontal windspeeds for United flight 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

16k. Vertical windspeeds for United flight 585.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

17. Rudder surface positions for United flight 585 assuming a

sustained equivalent control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

17a. Control wheel surface positions for United flight 585 assuming

a sustained equivalent control wheel input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

17b. Heading data for United flight 585 assuming a sustained equivalent

control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

17c. Normal load factor for United flight 585 assuming a sustained equivalent

control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

17d. Calibrated airspeed for United flight 585 assuming a sustained equivalent

control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

17e. Pitch angle data for United flight 585 assuming a sustained equivalent

control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

17f. Bank angle data for United flight 585 assuming a sustained equivalent

control wheel input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

18. United flight 585 rudder surface positions according to Boeing’s new

rotor model.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

18a. Rotational windshear encountered by United flight 585 according to

Boeing’s new rotor model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

18b. United flight 585 control wheel positions according to Boeing’s new

rotor model.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

18c. United flight 585 heading data according to Boeing’s new rotor model. . . . . . . . . . . . . . . . . . . . . 101

Figures viii Aircraft Accident Report

18d. United flight 585 bank angle data according to Boeing’s new rotor model. . . . . . . . . . . . . . . . . . . 102

18e. United flight 585 normal load factor data according to Boeing’s new rotor model. . . . . . . . . . . . . 102

18f. United flight 585 pitch angle according to Boeing’s new rotor model.. . . . . . . . . . . . . . . . . . . . . . 103

ix Aircraft Accident Report

Introduction to Amended Report

On March 3, 1991, about 0944 mountain standard time, United Airlines flight 585,

a Boeing 737-291 (737-200), N999UA, crashed while maneuvering to land on runway 35

at Colorado Springs Municipal Airport, Colorado Springs, Colorado. Flight 585 was

operating under the provisions of 14 Code of Federal Regulations Part 121 as a scheduled

domestic passenger flight from Denver, Colorado, to Colorado Springs. Numerous

witnesses reported that, shortly after completing its turn onto the final approach course,

the airplane rolled steadily to the right and pitched nose down until it reached a nearly

vertical attitude before hitting the ground. The 2 flight crewmembers, 3 flight attendants,

and 20 passengers aboard were killed, and the airplane was destroyed by impact forces

and fire.

On December 8, 1992, the National Transportation Safety Board adopted a final

report on the accident. The Safety Board concluded that it “could not identify conclusive

evidence to explain the loss of United Airlines flight 585.”

1

In its probable cause

statement, the Board indicated that it considered the two most likely explanations for the

sudden uncontrollable upset to be a malfunction of the airplane’s directional control

system or an encounter with an unusually severe atmospheric disturbance. The Board

further indicated in its probable cause statement that, although anomalies had been

identified in the accident airplane’s rudder control system, it was unable to identify a

condition under which any such anomaly would have produced a rudder movement that

the pilots could not have easily countered by the airplane's roll controls. Additionally, the

Board concluded that weather conditions in the Colorado Springs area at the time of the

accident were conducive to the formation of a horizontal axis vortex (rotor) and that some

witness observations supported the existence of a rotor at or near the time and place of the

accident. However, the Board determined that too little was known about the

characteristics of rotors to conclude whether a rotor was a factor in the accident.

Additional rudder- and weather-related information pertinent to the United

flight 585 accident was developed after the Safety Board’s adoption of its December 1992

final report. This information was developed in the course of the Board’s investigation of

the September 8, 1994, USAir flight 427 accident, which included an investigation of the

June 9, 1996, incident involving Eastwind Airlines flight 517

2

and a reexamination of

certain aspects of the United flight 585 accident. In its final report on the USAir flight 427

1

National Transportation Safety Board. 1992. Uncontrolled Collision With Terrain for Undetermined

Reasons, United Airlines Flight 585, Boeing 737-291, N999UA, 4 Miles South of Colorado Springs,

Colorado, March 3, 1991. Aircraft Accident Report NTSB/AAR-92/06. Washington, DC.

2

The Eastwind flight 517 incident was a yaw/roll upset that occurred near Richmond, Virginia. The

pilots of Eastwind flight 517 were able to regain control of the airplane and land without further incident.

Introduction to Amended Report x Aircraft Accident Report

accident,

3

the Safety Board adopted several conclusions that supplement and, in some

cases, contradict those that the Board adopted in its December 1992 final report on the

United flight 585 accident. Accordingly, the Safety Board has determined that the original

United flight 585 report should be amended to reflect the information and conclusions

contained in the USAir flight 427 report.

In this amended report, new or revised text that was added as a result of

information developed during the USAir flight 427 accident investigation is shown with a

change bar along the outside of the page. Although some additional corrections and

revisions have been made, the remainder of the report is substantially the same as the

December 1992 report.

3

National Transportation Safety Board. 1999. Uncontrolled Descent and Collision With Terrain,

USAir Flight 427, Boeing 737-300, N513AU, Near Aliquippa, Pennsylvania, September 8, 1994. Aircraft

Accident Report NTSB/AAR-99/01. Washington, DC.

xi Aircraft Accident Report

Abbreviations

A/P autopilot

ACARS aircraft communications addressing and reporting system

AD airworthiness directive

AFF Air Force Academy

agl above ground level

AMA area minimum altitude

AMIS aircraft maintenance information system

ANR airplane nose right

APU auxiliary power unit

ARTCC air route traffic control center

ATA Air Transport Association

ATC air traffic control

ATI S automated terminal information service

ATP airline transport pilot

AWS Air Weather Service

BAC British Aerospace Corporation

CAT clear air turbulence

CFR Code of Federal Regulations

Cg center of gravity

COS Colorado Springs Municipal Airport

CSD constant speed drive

CVR cockpit voice recorder

CWA center weather advisory

Abbreviations xii Aircraft Accident Report

CWSU center weather service unit

DEN Denver Stapleton International Airport

EDP engine-driven hydraulic pump

EPR engine pressure ratio

F Fahrenheit

FA area forecast

FAA Federal Aviation Administration

FAR Federal Aviation Regulations

FDR flight data recorder

FL flight level

FT terminal forecast

GOES Geostationary Operational Environmental Satellite

gpm gallons per minute

Hg Mercury

HPT high pressure turbine

HRC Hardness Rockwell C (scale)

Hz Hertz

IFR instrument flight rules

ILS instrument landing system

KCAS knots calibrated airspeed

KIAS knots indicated airspeed

Abbreviations xiii Aircraft Accident Report

LIDAR Light Distancing and Ranging

LLWAS low level windshear alert system

LLWS low level wind shear

LPT low pressure turbine

LVDT linear variable displacement transducer

LWD left wing down

MAC mean aerodynamic chord

McIDAS Man Computer Interactive Data Access System

MEL minimum equipment list

MPCU main power control unit

MSA minimum sector altitude

msl mean sea level

MST mountain standard time

N1 engine fan speed

N2 engine compressor speed

NASA National Aeronautics and Space Administration

NCAR National Center for Atmospheric Research

NIDA National Institute of Drug Abuse

NOAA National Oceanic and Atmospheric Administration

nmi nautical mile

NOTAM notice to airmen

NPRM notice of proposed rulemaking

NTSB National Transportation Safety Board

NWS National Weather Service

OTS Officer Training School

Abbreviations xiv Aircraft Accident Report

P/N part number

PAPI precision approach path indicator

PCU power control unit

PIREP pilot report

psi pounds per square inch

PST Pacific standard time

RRWDS radar remote weather display system

RWD right wing down

SEM scanning electron microscope

SIGMET significant meteorological information

TRACON terminal radar approach control

UAL United Airlines

USAF U.S. Air Force

VFR visual flight rules

VMC visual meteorological conditions

VORTAC very high frequency omnidirectional radio range/ultra high

frequency tactical air navigation aid

ZDV Denver Center

xv Aircraft Accident Report

Executive Summary

On March 3, 1991, a United Airlines Boeing 737, registration number N999UA,

operating as flight 585, was on a scheduled passenger flight from Denver, Colorado, to

Colorado Springs, Colorado. Visual meteorological conditions prevailed at the time, and

the flight was on an instrument flight rules flight plan. Numerous witnesses reported that

shortly after completing its turn onto the final approach course to runway 35 at Colorado

Springs Municipal Airport, about 0944 mountain standard time, the airplane rolled

steadily to the right and pitched nose down until it reached a nearly vertical attitude before

hitting the ground in an area known as Widefield Park. The airplane was destroyed, and

the 2 flight crewmembers, 3 flight attendants, and 20 passengers aboard were fatally

injured.

The National Transportation Safety Board determines that the probable cause of

the United Airlines flight 585 accident was a loss of control of the airplane resulting from

the movement of the rudder surface to its blowdown limit. The rudder surface most likely

deflected in a direction opposite to that commanded by the pilots as a result of a jam of the

main rudder power control unit servo valve secondary slide to the servo valve housing

offset from its neutral position and overtravel of the primary slide.

this page intentionally left blank

1 Aircraft Accident Report

1. Factual Information

1.1 History of Flight

On March 3, 1991, a United Airlines (UAL) Boeing 737, registration number

N999UA, operating as flight 585, was on a scheduled passenger flight from Denver,

Colorado, to Colorado Springs, Colorado. Visual meteorological conditions (VMC)

prevailed at the time, and the flight was on an instrument flight rules (IFR) flight plan.

Numerous witnesses reported that shortly after completing its turn onto the final approach

course to runway 35 at Colorado Springs Municipal Airport (COS), about 0944 Mountain

Standard Time, the airplane rolled steadily to the right and pitched nose down until it

reached a nearly vertical attitude before hitting the ground in an area known as Widefield

Park. The airplane was destroyed, and the 2 flight crewmembers, 3 flight attendants, and

20 passengers aboard were fatally injured.

Flight 585 originated in Peoria, Illinois, and the intended destination was Colorado

Springs, Colorado, at 0946.

4

It had intermediate stops in Moline, Illinois, and Denver,

Colorado. The flight was conducted under the requirements of 14 Code of Federal

Regulations (CFR) Part 121. The airplane departed Peoria on schedule at 0500 and arrived

in Moline 6 minutes behind schedule at 0532. It departed Moline on schedule at 0600 and

arrived at the Denver Stapleton International Airport (DEN) at 0800, 13 minutes ahead of

schedule.

The pilots for the Peoria to Moline to Denver segments of the flight reported that

there were no open maintenance writeups or deferred minimum equipment list (MEL)

items in the airplane's maintenance log. The pilots reported no abnormal situations related

to the airplane during the flight to Denver. A scheduled crew change took place in Denver.

The cargo manifests for the flight indicated that no hazardous material was on

board. The cargo bay areas contained passenger baggage, spindle assemblies, a casket, and

printed papers. Loading personnel reported that all of the cargo was properly restrained by

the pit cargo net/stanchions installed in the cargo bins.

The weather briefing message that the flightcrew received before departing Denver

included the 0750 Aviation Surface Weather Observation for Colorado Springs, as

follows:

Clear, visibility 100 miles, temperature 49 degrees F, dew point 9 degrees F, winds

330 degrees at 23 knots, gusts to 33 knots, altimeter setting 30.03 inches of Hg, cumulus

over the mountains northwest.

4

All times are Mountain Standard Time (MST) based on the 24-hour clock, unless otherwise

indicated.

Factual Information 2 Aircraft Accident Report

The UAL mechanic who was responsible for receipt and dispatch of the flight

reported that during his routine exterior inspection of the airplane, he found that the latch

on the electronics and equipment (E and E) door was not in its normal flush stowed

position. He checked the security of the door and stowed the latch. He stated that, “other

than that [stowage of the latch], the aircraft departed normally.”

Flight 585 departed Denver at 0923. The captain was flying the airplane and the

first officer was making the radio transmissions. The airplane was scheduled to arrive in

Colorado Springs at 0946. While en route to Colorado Springs, the flightcrew sent an

aircraft communications addressing and reporting system (ACARS) message updating its

estimated arrival time to 0942.

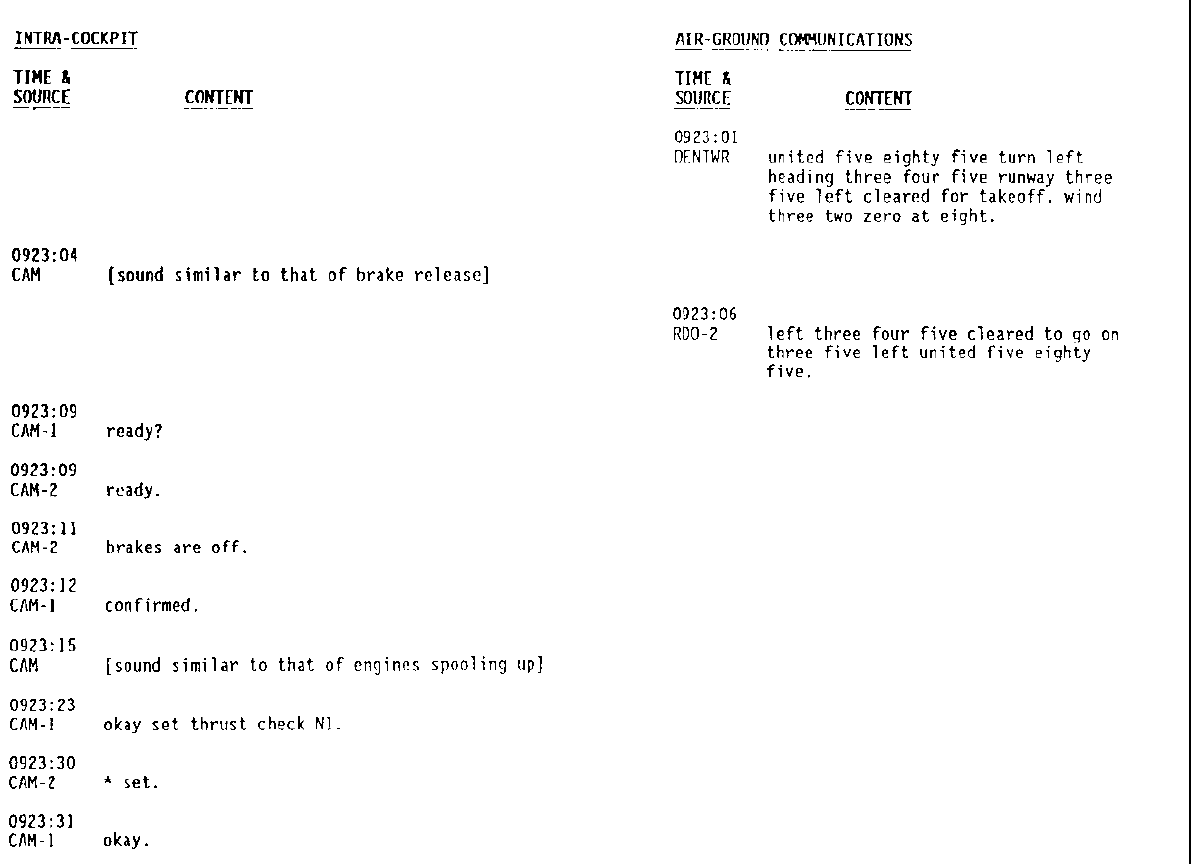

The cockpit voice recorder (CVR) tape revealed that at 0930:37, the flightcrew

received automated terminal information service (ATIS) information, version “Lima,” that

was about 40 minutes old. ATIS “Lima” stated, in part:

Wind three one zero at one three gust three five; low level wind shear advisories

are in effect; local aviation wind warning in effect calling for winds out of the northwest

gusts to forty knots and above.

According to the CVR and flight data recorder (FDR), the flightcrew added

20 knots to the approach landing reference target airspeed based on the ATIS information.

The full CVR transcript is contained in appendix D.

At 0932:35, the first officer reported their altitude to Colorado Springs Approach

Control as 11,000 feet, saying that they had received ATIS information “Lima.” Approach

Control then told the flight to depart the “Springs” VORTAC (very high frequency

omnidirectional radio range/ultra high frequency tactical air navigation aid) heading

165 degrees for a vector to runway 35 for a visual approach. Wind information was issued

as 320 degrees at 13 knots, gusting to 23 knots. At 0934:06, a descent was issued to

10,000 feet, at the pilot's discretion, and a further descent to 8,500 feet was issued about

3 minutes later. The first officer then reported the airport in sight, and approach control

instructed them to maintain “at or above 8,500 until on base, runway 35, cleared visual

approach, contact tower 119.9." She repeated the instructions and contacted the tower.

At 0937:59, the first officer reported to the tower, “...cleared for a visual to 35."

The local controller then cleared the flight to land and issued the wind as 320 degrees at

16 knots with gusts to 29 knots. The first officer then confirmed that they were cleared to

land on runway 35, and asked whether there were any reports of a loss or gain of airspeed

from other airplanes. The local controller replied that the last report was the one reported

by a Boeing 737. The first officer then asked the controller, “could you repeat it please?”

At 0938:29, the local controller replied that a Boeing 737 reported a 15-knot loss at

500 feet, at 400 feet “plus 15 knots,” and at 150 feet, “plus 20 knots.” The first officer

replied, “sounds adventurous, uh, United five eighty five, thank you.”

Airport traffic was issued to the flight by the tower controller at 0940:07,

“...eleven o'clock five miles northwest bound straight in for runway three zero.” The first

Factual Information 3 Aircraft Accident Report

officer replied that they would look for him and then asked how many miles the traffic

was from them. The local controller replied, “eleven to ten o'clock and five miles for

United five eighty five.” The first officer replied, “five eighty five, roger.” At 0940:44, the

first officer asked the controller the whereabouts of the traffic. The local controller

transmitted, “United 585, the Cessna traffic is ten to nine o'clock now as you're in your

turn, passing behind you, no factor.”

At 0941:23, the local controller directed the flight, “after landing, hold short of

runway three zero for departing traffic on runway three zero.” The first officer replied

“we'll hold short of three zero United five eighty five.” This transmission was the last one

received from flight 585.

More than 60 witnesses were interviewed during the initial field phase of the

investigation and more than 100 other witnesses came forward during a followup visit to

the accident site area about a year later. The majority of the witnesses who observed the

flight of the airplane on March 3, 1991, indicated that although the airplane was flying at

an altitude that was lower than what they were accustomed to seeing, it appeared to be

operating normally until it suddenly rolled to the right and descended into the ground.

Many witnesses reported that the airplane rolled wings level momentarily (as it

lined up with the runway) and that it rolled to the right until it was inverted with the nose

nearly straight down. Some of them saw the nose rise during the initiation of the right roll.

One elderly couple, who was reportedly walking through Widefield Park at the

time of the accident, stated to another witness that a liquid substance from the airplane fell

onto their clothing which “smelled very bad.” Repeated efforts to find and interview this

couple have been unsuccessful. These efforts included a door-to-door search of the houses

in close proximity to the park, a circulated composite picture of the male, as well as local

radio and television news coverage.

One witness, who was about 6 miles west of the accident site, reported seeing

several rotor clouds

5

in the area of the accident, 10 to 15 minutes before the crash. That

witness said that the rotor clouds were accompanied by thin wispy condensation. Another

person, who passed west of the accident site between 0830 and 0900, reported seeing

“torn wispy clouds” in the area of the accident.

Some witnesses reported seeing a white mist in the area of the right wing about the

time that the airplane began its rapid roll to the right. No other witnesses in the park, or

along the flightpath, reported liquid falling from the airplane.

In the final minute of the flight, evidence from the recorded radar data, the CVR,

and the FDR indicates that the normal acceleration varied between 0.6 and 1.3 G. The

airspeed was at about 155 knots with 2 to 10 knot excursions. At 0937:32, the flight had

5

Rotor: A vortex of air generated about a horizontal axis by high winds over irregular terrain.

Characteristics are similar to but less severe than a tornado. Rotors are sometimes evident by a cloud that

appears in the form of a stationary roll usually on the leeward side of a ridge. When viewed from the air, a

rotor cloud looks like a line of cumulus clouds.

Factual Information 4 Aircraft Accident Report

been cleared for a visual approach to runway 35 at Colorado Springs and the airplane was

approaching the extended runway centerline at 300 degrees, consistent with a 45 degree

intercept of the final approach path to the airport. The indicated altitude was 8,000 feet

and a descent was just commencing. Ten seconds later, the heading began to change about

0.5 degrees per second until the heading was 320 degrees. The thrust of each engine was

reduced from about 6,000 pounds to about 2,000 pounds approximately 40 seconds before

the crash. At that time, the airplane began descending at about 2,200 feet per minute, a

rate greater than required to remain on a standard approach to the airport. Several seconds

later the thrust was increased to about 3,000 pounds per engine.

About 20 seconds prior to the crash, the rate of heading change increased,

consistent with a 20-degree bank angle and a turn for alignment with the runway. Sixteen

seconds prior to the crash, the thrust was increased to about 6,000 pounds per engine. As

the thrust was increasing, the first officer made the “1,000 feet” call. Within the next

4 seconds, and about 9 seconds prior to the crash, the heading rate increased to about

5-degrees per second to the right, nearly twice that of a standard rate turn. The first officer

said “Oh God,” followed by the captain, in the last 8 seconds, calling for 15 degrees of

flaps. This selection of 15-degrees flaps, in combination with increased thrust, is

consistent with the initiation of a go-around. The altitude decreased rapidly, the indicated

airspeed increased to over 200 knots, and the normal acceleration increased to over 4 G.

The airplane impacted relatively flat terrain 3.47 nautical miles south of the south

end of runway 35 and .17 nautical miles to the east of the extended centerline of runway

35 at the Colorado Springs Municipal Airport. All of the occupants on board the flight

received fatal injuries. The airplane was destroyed by impact forces and postcrash fire.

The accident site coordinates were 38 degrees, 44 minutes and 09.4 seconds north

latitude, and 104 degrees, 42 minutes and 42.4 seconds west longitude at an elevation of

5,704 feet above sea level. The accident occurred during daylight hours.

1.2 Injuries to Persons

Injuries Crew Passengers Others Total

Fatal

5 20 0 25

Serious

0 0 0 0

Minor/None

0 0 -- 0

Total

5 20 0 25

Factual Information 5 Aircraft Accident Report

1.3 Damage to Aircraft

The airplane was destroyed by ground impact and postcrash fire. The value of the

airplane was estimated by UAL to be $14,200,000.

1.4 Other Damage

There was no damage to structures on the ground. Trees adjacent to the impact

crater were damaged by flying debris and soot, and nearby patches of grass north and

northeast of the crater were scorched. The size of the impact crater measured

approximately 39 feet by 24 feet and was about 15 feet deep.

1.5 Personnel Information

The flightcrew consisted of the captain, first officer, and three flight attendants.

(See appendix B).

1.5.1 The Captain

The captain, age 52, was hired by United Airlines on May 15, 1969. He possessed

a current Airline Transport Pilot (ATP) certificate and a current first class medical

certificate. He had accrued a total flight time of 9,902 hours, of which 1,732 hours were in

the B-737-200 that included 891 hours as captain.

This landing was the captain's first at COS as the pilot-in-command. However, it is

likely that the captain had landed many times at COS in the 16 years he had worked for

UAL as a flight crewmember. During the accident flight, he commented to the first officer

that he had “never driven to Colorado Springs and not gotten sick” (0927:31), signifying

that this was probably not his first landing or first experience with turbulence on the

segment to COS. He had conducted 14 flights into and out of Denver during the 90 days

before the accident.

First officers who had flown recently with the captain described his strict

adherence to standard operating procedures and his conservative approach to flying. They

indicated that the captain briefed all approaches even in visual conditions, always reported

equipment malfunctions, and discussed deferred maintenance items with the first officer.

The first officers also reported that, if the captain had not previously flown with a first

officer, he would observe that first officer perform pilot-flying duties during the first leg

of a trip sequence. Further, a first officer who had previously flown with the captain in

gusty, turbulent weather reported during a postaccident interview that the captain had

advised him to conduct a go-around if windshear was encountered. The first officer stated

that the captain had indicated that he had no problem with an early go-around and had

encouraged the first officer to conduct a go-around if he thought the approach was unsafe.

Factual Information 6 Aircraft Accident Report

1.5.2 The First Officer

The first officer, age 42, was hired by UAL on November 21, 1988, held a current

ATP certificate and a current first class medical certificate. She had accrued a total flight

time of 3,903 hours, including 1,077 hours as first officer in the B-737. This landing was

her second at COS.

The captain of United flight 585 had flown a 3-day trip sequence with the United

flight 585 first officer a few weeks before the accident and had described her to a friend as

“very competent.”

1.5.3 Flight Crew Activities

According to UAL records, the captain and the first officer were paired together

on a 3-day trip beginning on February 22, 1991 (that ended 6 days before the accident

trip).

The captain was off duty on February 25 and 26, and then flew a 3-day trip

beginning on February 27. The last day of the trip began with a departure from Seattle,

Washington, at 0726 Pacific standard time (PST) and ended with an arrival at San

Francisco, California, at 1330 PST. This trip was followed by a 2-day trip beginning on

March 2 (the accident trip), which was the captain's last scheduled trip before a 2-week

vacation. From March 23 through 25, the captain was scheduled to perform his annual

proficiency check.

The first officer flew a 3-day trip beginning on February 25, and she was off duty

on February 28 and March 1. The accident trip was not scheduled, but she volunteered for

it the previous night. According to the scheduler, she did not know the identity of the

captain when she accepted the trip.

The accident trip began with a reporting time of 0545 PST at Oakland, California,

on March 2, and a departure at 0735 PST. The first day consisted of landings at Los

Angeles, California, and Sacramento, California, and ended at 1828 MST with a landing

at Denver. After flying, the crew checked into the hotel at Denver at 1915, according to

hotel records. A UAL pilot, who was acquainted with the first officer, said he spoke with

both crewmembers when they arrived at the hotel. He said that the first officer invited him

to join her and the captain for dinner at a nearby restaurant, but since he had already eaten,

he declined the invitation.

The next day the crew checked out of the hotel at 0721 and took the 0730 courtesy

bus to the airport. The UAL pilot, who was taking a different bus, said he spoke again

briefly to the first officer. He said that she appeared alert and that she asked him about

what she could expect on a trip to Colorado Springs since it would be her first flight to

that airport. The pilot advised her to check the weather ahead since it could be a short

flight, and the first officer indicated she was familiar with short flight segments. A

member of the UAL training staff said that he greeted the captain around 0815 outside the

Factual Information 7 Aircraft Accident Report

Denver Operations/Dispatch area and that the captain seemed fine and “didn't look

unrested.” The Denver Customer Service Agent, who handled the departure of the

accident flight, said that the captain commented “we'll be back in a few minutes” as the

agent was closing the door (referring to the fact that the flight was scheduled to return to

Denver after landing at Colorado Springs). He described the captain as a “real

confident-type guy” and “very nice fellow” who appeared to be in exceptionally good

spirits. He described the first officer as a quiet person who “had her mind on what she

needed to get done.” He indicated that both crewmembers appeared rested and seemed to

get along well.

A check of Federal Aviation Administration (FAA) records showed that neither

the captain nor the first officer had any prior accidents, incidents, or violations.

1.5.4 Air Traffic Control Personnel

The local air traffic controller who was working the No. 1 position in the Colorado

Springs tower at the time of the accident became a full performance level controller at that

facility on August 11, 1990. The controller who was working the ground control/flight

data position in the tower at the time of the accident became a full performance level

controller at Colorado Springs on September 13, 1990.

The radar south controller position at the Denver terminal radar approach control

(TRACON) at the time of the accident was staffed by a full performance level controller

who had been certified on March 20, 1990.

1.6 Airplane Information

1.6.1 General

The airplane, a Boeing 737-291 Advanced, serial number 22742, was

manufactured in May 1982. (See appendix C). It was powered by two Pratt & Whitney

JT8D-17 engines. The airplane was owned and operated by UAL. It had been acquired by

UAL from Frontier Airlines on June 6, 1986.

By the accident date, the airplane had accumulated 26,050 hours and

19,734 cycles. Its most recent “C” check and Heavy Maintenance Check-4 was

accomplished by UAL on May 27, 1990. At that time the airplane had accumulated

24,004 hours and 18,298 cycles.

Weight and balance information was computer generated by UAL's load planning

function. The computerized model used input from passenger service, fueling, and ramp

cargo functions to provide closeout information to the flightcrew through ACARS.

Flight 585 departed Denver at a takeoff gross weight of 77,859 pounds. The center of

gravity (CG) at the time of takeoff was 25.3 percent of mean aerodynamic chord (MAC).

The forward and aft CG limits at the takeoff weight were 5 and 31.4 percent MAC,

Factual Information 8 Aircraft Accident Report

respectively. The weight at the time of the accident was 76,059 pounds, and the CG was

25.7 percent. This was based upon an estimated fuel burn of 1,800 pounds which was

generated from UAL's historical fuel burn records for the airplane.

1.6.2 Maintenance History

All UAL Aircraft Maintenance Information System (AMIS) entries for N999UA

from December 15, 1990, to March 2, 1991, were reviewed by the Safety Board, as well

as all nonroutine items from the last Heavy Maintenance Check-4 and “C” check. All

AMIS entries listed by the Air Transport Association (ATA) Specification 100, chapters

22 (Autopilot), 27 (Flight Controls), and 29 (Hydraulic Systems) for February 1988

through January 1991 were also reviewed.

The records review revealed that there had been five writeups from January 30,

1991, to February 6, 1991, stating that the No. 1 engine pressure ratio (EPR) was sluggish

and slow to respond. The final corrective action was recorded as: “Replaced transmitters,

replaced indicators, checked lines and fittings for leaks, finally flushed manifold and

probes.”

On February 14, 1991, the flightcrew reported that the CAT II coupled approach

was unsatisfactory. They said that the airplane “tried to land to left of [the] runway.” The

corrective action was signed off as: “Accomplished full ground CAT II system check, OK.

Returned aircraft to CAT II status.” On February 15, 1991, the flightcrew reported: “Last

two coupled approaches have been excellent. Autopilot checks good per maintenance

manual.”

On February 25, 1991, the flightcrew reported: “On departure got an abnormal

input to [the] rudder that went away. Pulled yaw damper circuit breaker.” The corrective

action was signed off as: “Replaced yaw damper coupler and tested per [the] maintenance

manual.” Interviews with the flightcrew of that flight indicated that, at the time of the

event, the airplane was between 10,000 feet and 12,000 feet mean sea level (msl) at an

indicated airspeed of 280 knots, in smooth air with the landing gear and flaps up. The first

officer was flying the airplane with the autopilot off. The flight had just leveled off, and

the first officer was in the process of retarding the power levers to the cruise setting when

there was an uncommanded yaw. He estimated that the yaw was to the right 5 to

10 degrees. In the time that it took him to close the throttles, everything returned to

normal. The first officer did not recall any uncommanded movement of the rudder pedals.

The yaw damper was turned off and its circuit breaker was pulled before landing.

On February 27, 1991, a writeup by the flightcrew stated “Yaw damper abruptly

moves [the] rudder occasionally for no apparent reason on [the] “B” actuators. Problem

most likely [is] in [the] yaw damper coupler...unintended rudder input on climbout at FL

[flight level] 250. A/P [auto-pilot] not in use, turned yaw damper switch off and pulled

[the] circuit breaker. Two inputs, one rather large deflection....” The corrective action was

signed off as: “Replaced rudder transfer valve and [the] system checks OK.” Interviews

with the flightcrew of the flight revealed that the first officer was flying the airplane and

Factual Information 9 Aircraft Accident Report

indicated that he believed that his feet were on the rudder pedals at the time of the event.

While climbing through 10,000 feet, he said he experienced several rapid “jerks” that he

could not identify. The flight encountered light turbulence at the time. While continuing

the climb between 25,000 feet and 28,000 feet, he said he felt a significant right rudder

input which lasted between 5 and 10 seconds. The airplane was still in light turbulence

and at 280 knots. Although he was not sure if his feet were on the rudder pedals during

this later occurrence, he reacted by centering the ball with left rudder input and normal

flight was resumed. Both crewmembers looked up at the overhead panel and saw the

No. 1 constant speed drive (CSD) low oil pressure light illuminated. The yaw damper was

turned off and its circuit breaker was pulled. The CSD light went out, then came back on

about 5 minutes later. The CSD was disconnected, and no further anomalies were

experienced during the remainder of the flight or subsequent flights.

There were no open maintenance items when the airplane departed Denver on

March 3, 1991. No other maintenance items were found in the AMIS review that appeared

related to the accident circumstances.

All applicable Airworthiness Directives (ADs) had been complied with. Required

actions that were not yet accomplished were within the time limits specified in the AD.

The hydraulic rudder actuator, standby actuator, transfer valve, and yaw damper

coupler are “on condition”

6

items in the United Airlines maintenance program.

Subsequent to the records review, the history of the standby rudder actuator was

reviewed in detail because of discrepancies found during the actuator's disassembly (see

section 1.12.3.2 of this report.) The actuator was manufactured on October 3, 1981, by

Hydraulic Units, Inc.—now Dowty Aerospace. It had been installed on N999UA by

Boeing during manufacture of the airplane. It had not been removed from the airplane by

either Frontier Airlines or by UAL. It was identified by the manufacturer's part

number 1U1150-1 and Boeing part number BAC10-60797-4, serial number 0953.

1.6.3 Boeing 737 Hydraulic System Information

Hydraulic power on the 737-200 is provided by three independent hydraulic

systems, each of which is capable of operating pressures of about 2,950 pounds per square

inch (psi). The systems are designated as hydraulic system A, hydraulic system B, and the

standby hydraulic system. Hydraulic systems A and B have independent hydraulic

reservoirs and two hydraulic pumps each. Although hydraulic systems A and B normally

operate together to provide dual hydraulic power for primary flight controls (ailerons,

elevators, and rudder), either system is capable of powering the flight controls alone if the

other system fails. Further, if one of the hydraulic pumps in either the A or B systems

were to fail, the remaining pump has sufficient capacity to provide full flight control

authority for its respective system operation. If needed, the ailerons and elevators can also

6

“On condition” means that maintenance is performed only after a defect is noted during inspection,

rather than on a time or cycle basis.

Factual Information 10 Aircraft Accident Report

be operated manually, without hydraulic power, and the rudder may be operated with the

standby hydraulic system.

The 737-200 hydraulic system A is powered by two engine-driven hydraulic

pumps (one driven by each engine). The 737 hydraulic system A provides power for flight

controls, landing gear, nose gear steering, alternate brakes, inboard flight spoilers, engine

thrust reversers, and ground spoilers. The landing gear may be lowered hydraulically with

hydraulic system A power or released to a free fall manually.

The 737-200 hydraulic system B is powered by two electric motor-driven

hydraulic pumps (one driven by each engine). Hydraulic system B provides power for

flight controls, normal brakes, trailing edge flaps, leading edge flaps and slats, and

outboard flight spoilers.

The 737-200 standby hydraulic system is unpressurized during normal operations.

This system is powered by an electric pump and can be activated manually by the pilots

by arming “ALTERNATE FLAPS” or selecting the hydraulic system A or B flight control

switch to “STBY RUD” (standby rudder) on the overhead panel in the cockpit.

7

This

standby hydraulic system powers the standby rudder system, provides an alternate source

of power for both engine thrust reversers, and extends the leading edge flaps and slats in

the ALTERNATE FLAPS mode.

Two flight control hydraulic modules (one each for hydraulic systems A and B)

are installed. Each hydraulic module is a manifold assembly containing a spoiler shutoff

valve, flight control shutoff valve, low-pressure warning switch, and compensator

cartridge. The compensator cartridge maintains return fluid from the aileron, rudder, and

elevator power control units (PCU) after hydraulic system shutdown. This fluid is used to

compensate for volume changes in the hydraulic system because of temperature changes

or fluid loss. Motor-operated shutoff valves within the module are commanded to their

operating positions by the flight control system switches in the cockpit. Figure 1

illustrates the hydraulic system panel.

7

During normal operation, the hydraulic system A and B flight control switches would be in the ON

position and the ALTERNATE FLAPS switch would be in the OFF position.

Factual Information 11 Aircraft Accident Report

Figure 1. Boeing 737-200 hydraulic system panel.

1.6.4 Boeing 737 Flight Control Systems

The flight controls on the 737 are the ailerons, flight spoilers, elevators, horizontal

stabilizer, rudder, flaps, and slats. Flight control about the longitudinal (roll) axis of the

airplane is provided by an aileron on each wing assisted by two flight spoilers. Flight

OVERHEAT

OVERHEAT

LOW

PRESSURE

LOW

PRESSURE

LOW

PRESSURE

LOW

PRESSURE

YAW

DAMPER

MACH TRIM

FAIL

B LOW

QUANTITY

FEEL

DIFF PRESS

LOW

PRESSURE

STANDBY

HYD

LOW

QUANTITY

FLT CONTROL

SPOILER

YAW DAMPER

MACH TRIM

ALTERNATE FLAPS

LOW

PRESSURE

LOW

PRESSURE

1 ENG 2

1 ELEC 2

OFF

ON

A

CLOSE OPEN

OFF

ON

B

HYD PUMPS

GRD INTERCONNECT

A B

A B

STDBY

RUD

OFF

A ON

STDBY

RUD

OFF

B ON

OFF

ARM

OFF

ON

OFF

ON

TEST

OFF

ON

UP

DOWN

OFF

Factual Information 12 Aircraft Accident Report

control about the lateral (pitch) axis is provided by the horizontal stabilizer and two

elevators. Flight control about the vertical or directional (yaw) axis is provided by the

single-panel rudder.

8

The ailerons and flight spoilers (roll control) are operated by moving

the control wheel clockwise or counter-clockwise,

9

the elevator (pitch control) is operated

by moving the control column forward or aft, and the rudder (directional/yaw control) is

operated by moving either the right or left rudder pedal forward or aft. Figure 2 depicts

the three axes of motion, and figure 3 shows the flight control surface locations.

Figure 2. Three axes of motion.

8

For more information about the rudder design, see section 1.6.4.1.

9

A clockwise control wheel input commands roll in a right-wing-down (RWD) direction, whereas a

counter-clockwise control wheel input commands roll in a left-wing-down (LWD) direction. In this report,

clockwise and counter-clockwise control wheel inputs will be described as right and left control wheel

inputs, respectively.

Factual Information 13 Aircraft Accident Report

Figure 3. Boeing 737 flight control surface locations.

Boeing stated that the 737 roll and yaw control systems were designed to be

capable of countering the effects of failures (such as loss of power on one engine, flap

and/or slat asymmetries, and hydraulic system failure) and achieve the desired crosswind

control capability. According to Boeing, the 737 is aerodynamically cross-coupled (as are

most airplanes); that is, motions about the roll and the yaw axes constantly interact and

affect each other in flight. Thus, any yawing motion (sideslip) would cause the airplane to

roll unless countered by the control wheel.

1.6.4.1 Rudder Control System

The 737-200 has a single rudder panel actuated by a single hydraulic rudder PCU.

A standby rudder actuator is available to move the rudder if hydraulic systems A and/or B

fail. According to a Safety Board review of large transport-category airplanes (including

Boeing, McDonnell Douglas, Airbus, and Lockheed models), the 737 is the only twin

wing-mounted engine, large transport-category airplane designed with a single rudder

panel and single rudder actuator. All other large transport-category airplanes with twin

wing-mounted engines were designed with a split rudder panel, multiple hydraulic

actuators, or a mechanical/manual/trim tab rudder actuation system.

Pilot control of the 737-200 rudder is transmitted in a closed-loop system from the

pilots’ rudder pedals in the cockpit through a single cable system to the airplane’s tail

section and then through linkages to the main rudder PCU and a standby rudder PCU in

the aft portion of the vertical stabilizer. The rudder pedals at each pilot position are located

on either side of the control column stem, which is protected within a housing (commonly

Angle of Airflow Sensors

Leading Edge Flaps

Leading Edge Slats

Flight Spoilers

Trailing Edge Flaps

Ailerons

Stabilizer

Balance Tabs

Elevator

Rudder

Ground Spoilers

Factual Information 14 Aircraft Accident Report

termed the “doghouse” by 737 flight crews) that is located between each pilots’ lower legs

at the pilot positions. Figures 4 and 4a show the 737 rudder system.

According to Boeing personnel, because of the engine placements on the wings,

the 737 rudder has to be sufficiently powerful to effectively counter the effects of a loss of

engine power on one side during a maximum gross weight takeoff at low airspeeds,

especially in crosswind conditions. A loss of engine power on one side of the airplane

would result in a large yawing moment, in the direction of the inoperative engine,

produced by thrust from the operating engine. The loss of engine power can be countered

by a rudder input in the opposite direction (for example, left pedal input to counter loss of

power on the right engine).

10

Figure 4. Boeing 737 rudder system.

10

The rudders on airplanes with fuselage-mounted engines are typically less powerful than the rudders

on airplanes with wing-mounted engines. The rudders for fuselage-mounted engine airplanes do not have to

be designed to counter as significant an asymmetrical thrust effect in the event of a loss of power on one

engine. Because the rudder on airplanes with fuselage-mounted engines is less powerful, the consequences

of a rudder hardover are less serious; thus, the Safety Board’s investigation did not consider this type of

airplane.

Standby Rudder PCU

Captain’s Rudder Pedals

Switch and Indicator

Rudder Control Cables

Aft Torque Tube

Feel and

Centering Unit

Left Rudder Motion

Electric Rudder Trim Actuator

Rudder Hinge

Line

Aft Rudder Power

Control Unit Input Rod

Rudder Main PCU

Factual Information 15 Aircraft Accident Report

Figure 4a. Detailed view of 737 aft rudder system controls and linkages.

When properly installed and rigged, the 737-200 main rudder PCU can command

a maximum deflection of 26° to the right and the left of the rudder’s neutral position

(under no aerodynamic load conditions); the rudder can travel to those limits at a

maximum rate of 66° per second. (The 737 main rudder PCU is capable of producing

about 5,900 pounds of output force to move the rudder when both hydraulic systems are

operating at their normal operating pressure—2,950 psi each.) The rudder pedals move

about 1 inch (from their neutral position) for every 6.5° of rudder surface travel (under no

aerodynamic load conditions) until the rudder pedals reach their maximum travel of about

4 inches (backward and forward) from the neutral position. The rudder pedal stops at the

pilots’ forward rudder control quadrant are set to provide a mechanical stop at 28° of

rudder travel (exceeding the rudder’s travel authority) because compliance in the cable

system (cable stretch) may require rudder pedal travel beyond the 4-inch limit to achieve

the full travel rudder movement of 26°. With the aerodynamic loads encountered in flight,

the available amount of rudder surface travel is reduced. The maximum amount of rudder

Upper Crank

Standby Power

Unit Input Rod

Aft Torque Tube

Center Crank

Lower Crank

(Bell Crank)

Rudder Power

Control Unit

Input Rod

Aft Rudder Control

Quadrant Input

Rod

Trim and

Feel Rod

Cable RB

Cable RA

AFT Quadrant

Factual Information 16 Aircraft Accident Report

travel available for an airplane at a given flight condition/configuration is referred to as

the rudder’s “blowdown” limit.

11

The rudder feel and centering unit is attached to the aft rudder torque tube in the

vertical fin, forward of the main rudder PCU (see figure 4). This unit holds the rudder at

the neutral (or trimmed) position when no rudder pedal force is applied. It also provides a

feedback force to the rudder pedals that increases as the rudder pedals are depressed. The

pilot rudder pedal force required for full rudder deflection is about 70 pounds; however,

the rudder trim system allows the pilots to maintain a rudder deflection without having to

maintain a rudder pedal force.

During normal and abnormal operations, the rudder can be moved beyond the

movement commanded by the hydraulic actuator through a pilot’s application of force on

the rudder pedals. (Normal operation of the rudder refers to the rudder’s motion, or lack

thereof, resulting from normal PCU servo valve operation. Abnormal operation refers to

the rudder’s motion that results from a PCU servo valve that is functioning abnormally,

for example, because of a rudder jam and/or reversal.

12

Both types of operation can

include rudder movement within the range of the rudder authority on the ground and/or to

the rudder’s in-flight blowdown limit.)

During normal rudder operation, if a pilot applies a sufficiently rapid rudder pedal

input (the rudder pedal must move faster than the PCU’s ability to respond to the input),

the PCU input crank would contact the PCU external body stop (manifold stop),

transmitting force from the rudder pedal input to the rudder surface through the main

rudder PCU and the rudder system's linkages. Also, the additional force applied by the

pilot would increase the rudder PCU output force, moving the rudder farther in the

intended direction of travel. The rudder feel and centering unit would oppose the rudder

pedal force (decrease the force applied by the pilot’s foot)

13

with about 9 to 70 pounds of

force, depending on how far the rudder is away from its centered position.

During normal operation of the rudder in flight, if a pilot applied between 9 and

70 pounds of force to a rudder pedal, the rudder would move in response until it reached

its blowdown limit (when the aerodynamic forces acting on the rudder surface equal the

hydraulic actuator force). According to Boeing engineers, if the pilot were to then apply

additional force to the rudder pedal, the pedal would move about 1 inch farther, with no

corresponding movement of the rudder, as the slack in the rudder linkage system is

removed and the external input crank contacts the external stop. Any additional pilot

application of force to the rudder pedal would result in rudder pedal movement of about

11

Rudder blowdown is the maximum rudder angle resulting from a pilot-commanded full rudder input

under the existing flight conditions. It represents a balance between the aerodynamic forces acting on the

rudder and the mechanical forces produced by the PCU. The maximum rudder angle can be increased

beyond that produced by the hydraulic force if the pilot exerts sufficient force on the rudder pedals.

12

Rudder reversals are discussed in sections 1.16.5.3, 1.16.5.4, and 1.16.5.5.

13

U.S. Air Force (USAF) ergonomic studies indicate that the maximum rudder pedal force pilots can

exert on the rudder pedals is about 500 pounds. For additional information regarding pilot rudder pedal

force, see section 1.18.3 of this revised report.

Factual Information 17 Aircraft Accident Report

1 inch for each 300 pounds of rudder pedal force, which in turn would move the rudder

surface slightly beyond the maximum deflection possible from the hydraulic actuator

force.

During a servo valve jam/rudder reversal, the rudder pedal force from a pilot

resisting the jam would cause the rudder to move in the direction opposite the jam (toward

the rudder’s neutral position). The feel and centering unit would add to the rudder pedal

force. As a pilot applied force to a rudder pedal in opposition to the jam/reversal, the first

inch of movement of the pedal would cause the PCU input crank to move to the PCU

manifold body stop. After the PCU input crank contacts the manifold body stop,

approximately 300 additional pounds of pilot rudder pedal force would be required to

move the rudder pedal each additional 1 inch of travel until the rudder pedal contacts the

forward quadrant stops. Pilot rudder pedal force in opposition to a jammed/reversing

rudder malfunction would reduce the deflection of the rudder.

The 737 rudder trim system allows the pilots to command a steady rudder input

without maintaining foot pressure on the rudder pedals. The primary purpose for rudder

trim is to compensate for the sustained large yawing moments generated by asymmetric

thrust in an engine-out situation. Pilots also sometimes use a small amount of rudder trim

during normal flight to compensate for slight yawing moment asymmetries such as those

caused by flight control and engine rigging imperfections. To trim the rudder on the

737-100 and -200, the flight crew turns a knob on the flight deck center pedestal that is

mechanically connected to the rudder trim actuator at the feel and centering unit. The

rudder trim actuator (located near the aft control torque tube in the vertical fin) rotates the

feel and centering unit, thus changing the neutral, or zero, position of the rudder. The

rudder trim moves within its maximum authority of ± 16°.

The 737 yaw damper system improves ride comfort by sensing turbulence- or