Commercial Vehicle Pre-Trip Inspection Checklist

You are only required to inspect the items on the CDL Vehicle Inspection checklist. You may use the checklist

provided in this section for your test and check o items as you have completed them, but NO additional markings

or writing may be placed on this list prior to the test. You MUST name, point to and/or touch and fully explain to the

examiner WHAT you are inspecting each safety critical item for. If you do not, you will not get credit for the item(s).

Department of Public Safety Driver and Vehicle Services - 445 Minnesota St., Saint Paul, MN 55101

Phone: (651) 201-7626 TTY: (651) 282-6555 Fax: (651) 296-5316

Rev. October 2023

Section 10M - Vehicle Inspection Page 10M-11

Version: September 9, 2022

Class A Checklist

Tractor Semi-Trailer or Truck & Trailer or Bus & Trailer

In-Vehicle/Engine Start

☐ *air or *hydraulic brake check

☐ parking & trailer brake check

☐ service brake check

☐ lighting indicators

☐ emergency equipment

☐ windshield & traffic monitoring devices

☐ wipers & washers

☐ heater & defroster

☐ horn(s)

Lights Operations Check

☐ all external lights

Front of Vehicle/Engine Area

☐ lenses

☐ fluid levels

☐ fluid & air leaks

☐ steering systems

Steering Axle

☐ tires

☐ rims

☐ lug nuts

☐ springs/mounts & air bags & shocks

☐ brake lines or hoses & leaks

☐ brake contaminates

Side of Vehicle

☐ lenses & reflectors

☐ traffic monitoring devices

☐ battery

☐ fuel tank(s)/DEF tank

☐ frame(s)

Combination Vehicles Only

☐ air & electric lines & connectors

☐ fifth wheel skid plate or pintle hook

or tow hitch

☐ kingpin & apron & gap or drawbar ring &

tongue or coupler & tongue

☐ locking & safety devices

Trailer Only

☐ landing gear & clearance

☐ reflective tape

Rear of Trailer

☐ lenses & reflectors

* Automatic failure if not performed correctly

Passenger and School Bus

Only

☐ passenger entry & lift

☐ emergency exits

☐ passenger seating

☐

passenger monitoring devices

School Bus Only

☐ student lights (front & back)

☐ stop arm(s) & safety arm

☐ first aid & body fluid kits

zŽƵĂƌĞŽŶůLJƌĞƋƵŝƌĞĚƚŽŝŶƐƉĞĐƚƚŚĞŝƚĞŵƐŽŶƚŚĞ>sĞŚŝĐůĞ/ŶƐƉĞĐƚŝŽŶĐŚĞĐŬůŝƐƚ͘You may use this checklist

for your test and check off items as you have completed them, NO additional markings or writing may be

placed on this list. You MUST name, point to and/or touch and fully explain what you are inspecting

each safety critical item for. If you do not do so, you will not get credit for the item(s).

The Commercial Vehicle Pre-Trip Inspection Test is designed to test your ability to check a variety of commercial vehicle safety

equipment and vehicle components. You are required to check the items listed below that relate to the operation of your vehi-

cle. You will need to point out the item to be checked and explain how you check that item. You may use this checklist during

your pre-trip inspection.

All commercial vehicles must display a current inspection sticker to receive a road test.

READ MN CDL MANUAL SECTION 10M PAGES 189-200

(Remember to latch the hood.)

1

PG. 3

PG. 4

PG. 4

PG. 4 & 5

PG. 5

PG. 6

PG. 6

PG. 6

Department of Public Safety Driver and Vehicle Services - 445 Minnesota St., Saint Paul, MN 55101

Phone: (651) 201-7626 TTY: (651) 282-6555 Fax: (651) 296-5316

Rev. October 2023

Section 10M - Vehicle Inspection Page 10M-12

Version: September 9, 2022

Class B or Class C Checklist

Straight Truck or Other Straight Vehicle

In-Vehicle/Engine Start

☐ *air or *hydraulic brake check

☐ parking & trailer brake check

☐ service brake check

☐ lighting indicators

☐ emergency equipment

☐ windshield & traffic monitoring devices

☐ wipers & washers

☐ heater & defroster

☐ horn(s)

Lights Operations Check

☐ all external lights

Front of Vehicle/Engine Area

☐ lenses

☐ fluid levels

☐ fluid & air leaks

☐ steering systems

Steering Axle

☐ tires

☐ rims

☐ lug nuts

☐ springs/mounts & air bags & shocks

☐ brake lines or hoses & leaks

☐ brake contaminates

Side of Vehicle

☐ lenses & reflectors

☐ traffic monitoring devices

☐ battery

☐ fuel tank(s)/DEF tank

☐ frame(s)

Rear of Vehicle

☐ lenses & reflectors

* Automatic failure if not performed correctly

zŽƵĂƌĞŽŶůLJƌĞƋƵŝƌĞĚƚŽŝŶƐƉĞĐƚƚŚĞŝƚĞŵƐŽŶƚŚĞ>sĞŚŝĐůĞ/ŶƐƉĞĐƚŝŽŶĐŚĞĐŬůŝƐƚ͘You may use this checklist

for your test and check off items as you have completed them, NO additional markings or writing may be

placed on this list. You MUST name, point to and/or touch and fully explain what you are inspecting

each safety critical item for. If you do not do so, you will not get credit for the item(s).

Commercial Vehicle Pre-Trip Inspection Checklist

You are only required to inspect the items on the CDL Vehicle Inspection checklist. You may use the checklist

provided in this section for your test and check o items as you have completed them, but NO additional markings

or writing may be placed on this list prior to the test. You MUST name, point to and/or touch and fully explain to the

examiner WHAT you are inspecting each safety critical item for. If you do not, you will not get credit for the item(s).

The Commercial Vehicle Pre-Trip Inspection Test is designed to test your ability to check a variety of commercial vehicle safety

equipment and vehicle components. You are required to check the items listed below that relate to the operation of your vehi-

cle. You will need to point out the item to be checked and explain how you check that item. You may use this checklist during

your pre-trip inspection.

All commercial vehicles must display a current inspection sticker to receive a road test.

READ MN CDL MANUAL SECTION 10M PAGES 189-200

(Remember to latch the hood.)

2

INSIDE VEHICLE

Safe start: SHOW: Before starting the truck, pull on the parking & trailer brake valves brake is

on and then show the transmission is in neutral.” Start the truck.

AIR BRAKE CHECK*:

1. Air Gauge &

Governor Cuto

Check Explain: Air Gauges read at the safe level (90-120 psi). Explain, I would Chock the wheels, (leave

both the parking and trailer brakes pushed in, gently press service brake and gas pedal) start the

vehicleandinspectthattheairgaugeisworkingandbuildstheairpressuretogovernorcuto

(approximately125–140psi)andidentifythecutopressureforyourvehicle.

2. Air Loss check (leave both the parking and trailer brakes pushed in, and keep your foot on the brake pedal)

Put the truck in neutral, turn o the truck but turn the key back to the ON position;

Both parking brake valves should be released. Explain: “I should not lose more than 4 psi per

minute.” (3 psi for class B.) Wait the full minute while holding the service brakes.

3. Low Air Alarm

check: Explain: “The Low Air Alarm should come on between 80 - 60 psi.” Start to pump the brakes

slowly until alarm sounds. Explain: “Alarms work. Both visible and audible.”

Emergency Brake

check:

Both parking brake valves should still be pushed in and released at this time. Explain: “Both valves

should pop out and apply automatically between 40 - 20 psi.” Start to pump the brakes until both

valves apply. Immediately start the engine, put the truck in drive and try to pull against the brakes.

Explain: “Emergency brakes hold.” Put the truck in neutral and build air pressure to at least 90 psi.

Parking &

Trailer Brake Check

Step 1. Parking Brake:

Release

(push in)

trailer brake (red valve) leaving yellow valve applied and put the truck

in drive. Gently pull against the parking brake; truck should not move;

Explain: “Parking brake Holds.”

Step 2. Trailer Brake

& connection Release (push in) parking brake (yellow valve) and pull the trailer brake (red valve) out.

Gently pull truck forward Explain: “Trailer Brake Holds.” Leave the trailer brake

(red valve) out. Explain: “Now Testing Trailer Connection, to show hitch is securely

locked and coupled together.” Then gently pull truck forward and

Explain,“Trailer Brake holds the truck and trailer is connected securely.”

Service brake: Release all parking & trailer brakes, put the truck in drive, roll forward and stop with service brake

(brake pedal); “Service brake works and also brakes evenly apply without pulling to either side.”

Lighting indicators: Turnonlightsandcheckbothinsideturnsignalindicatorsandashers.

Turn on head lights and check the high beam indicator. Explain: ABS Light is not ON and

DEF is full and now warning lights are visible.

Emergency Equip: Sparefuses;3reectivetriangles;properlychargedandmountedsecuredreextinguisher.

Windshield

& mirrors: Windshield is clean, clear, and not cracked. No illegal stickers and nothing blocking my view.

The mirrors are clean, clear, and adjusted properly.

Wipers & washers: Thewiperbladesarenotcrackedormissingandoperatesmoothly.Testthewasheruid.

Heater & defroster: Turn on the fan and test (twist) the heater/defroster controls to see if it works.

Horn: Toot the horn/s, explain city horn works, and if equipped air/freeway horn works.

3

Lights Operation Check:

(Leave lights on and truck idling, Mention to examiner I now will check all my lights):

All External Lights:

Low Beams: Check front;

High Beams: Check front;

Running Lights: Check all sides of truck and trailer and top of cab.

Right turn signal: Get out and check front & back;

Left turn signal: Check front & back;

Hazard/Flashers: Check front & back;

Brake Lights: Ask the examiner to help you check the brake lights.

Front of Vehicle/Engine Area

Lenses Lights&reectors:Lightsarenotcracked,looseormissing.Theyareallclean,clearand

propercolor(amber=front).Reectorsareclean,clearnotcracked,looseormissing.Wiresare

connected, not corroded, exposed or loose. All securely mounted.

(Do not actually check the uid level, but explain how you would.)

Fluid Level Oil level check whileengineiso,removeyellowdipstick,andshouldbeaboveaddmark,if

below, point to where it should be added. Cap is not loose, cracked or leaking and is securely

mounted.

Coolant level is at ADD & FULL lines, should be above the add mark. If below, point to where

it should be added. The Reservoir is mounted securely, not cracked or leaking, not missing nuts

or bolts, hoses are not loose, cracked or leaking, Securely Mounted.

Power steering Fluid Should be above the minimum/add mark (checked while engine is

running on automatic only.) Reservoir mounted securely, not cracked or leaking, not missing

nuts or bolts, hoses are not loose, cracked or leaking, and are securely mounted.

Automatic Transmission Fluid Automatic transmissions only,

Check Red dipstick - Should be above the add mark (while the engine is running), If low add

where I check it.

Fluid & Air Leaks: Smell for burnt rubber or plastic. Look for leaks or puddles on top of motor,

near the radiator and under the engine compartment. Hoses should not be cracked, worn

through, loose or leaking, no loose or missing hose clamps.

Steering box

& hoses: Steering box is not twisted, sagging, or loose; no missing nuts or bolts; not leaking.

Hose; they’re no abrasions bulges or cuts; not leaking.

Steering linkage:

the steering shaft, pitman arm and drag link are not cracked, bent, dented or

loose; no missing nuts or bolts, bushings and joints are greased. Castle nuts and cotter keys

Note: if equipped are not missing, cracked or loose. Note: some trucks have only nuts and

bolts. Check for excessive play at the steering shaft not more than 10 degrees of play at the shaft

or 2 inches at the steering wheel.

Tires Tire tread is virgin tread not recapped, tread depth is not worn dangerously thin it’s at least

4/32deep,evenlyworn,noatspots,sidewalls,arenotcrackedwornthroughorleaking.

I’dcheckforproperinationatvalvestemandwithanairgauge.Tiresareproperlyinated,no

missing dust caps and are securely mounted.

Rims Rims are not warped, cracked, bent or dented, there is no gap, illegal welds or exposed bead

between the tire and rim. The tire is sealed to the rim, and is securely mounted.

Lug Nuts Lug nuts are None are loose, missing or cracked, no gap between nut and rim, no shiny

threads or rust trails. All securely mounted.

(Remember to latch the hood.)

4

Springs/Mounts/Airbag & Shocks

Springs Springs The metal is cracked, bent or dented, rusted through, not sagging or loose; Springs

not scissoring, no missing nuts or bolts, Securely Mounted.

Mounts Spring mounts, The metal is not bent, cracked, or dented; not twisted, sagging or loose, no

gaps or missing bolts. No torn or missing bushings and are securely mounted. The spring

U-Bolt mounts Not cracked, bent, or dented; not twisted, sagging or loose; no missing nuts

and are Securely Mounted.

Airbag Air bags, NoAbrasions,BulgesorCuts,notleaking;eveninationonbothairbags.

Shocks Shocks are not cracked, bent or dented, rusted through, twisted sagging or loose, they’re not

leaking. Bushings not torn or missing, no missing nuts or bolts, and securely mounted.

Brake hoses/Lines

/Leaks: Brake hoses, No Abrasions, bulges or cuts; no leaks or missing hose clamps. ABS line they’re

no corroded, exposed or loose wires. Securely Mounted.

Brake contaminates: Check for no discoloration, signs of over-heating, drums are not warped, cracked, or welded

drums; linings, at least 1/4 thick, evenly worn, they’re dry -no grease or oil., mud or rocks

or debris, inside the drums or on the linings, securely mounted (automatic only) must look

through inspection holes:

Lenses & Reectors

(FRONT & SIDE OF VEHICLE) Lenses are not cracked, loose or missing.

Theyareallclean,clearandpropercolor(amber=front,red=rear).Reectorsareclean,clear

not cracked, loose or missing. Wires are connected not corroded,

exposed or loose All securely mounted..

(REAR OF TRUCK) DOT approved tape, clean and clear, Wires are connected, Not corroded,

exposedorloosewires.Lensesareclearnotcracked,securelymounted.Reectorsareclean,

clear not cracked, loose or missing. All are securely mounted (and the proper color red = rear).

(REAR OF TRAILER) DOT approved tape is clean and clear and covers at least 100%,

Wires are connected, Not corroded, exposed or loose lights are clean, clear not cracked,

securely mounted. Proper color (red=rear)

Trac Monitoring

Devices:

(Mirrors) Mirrors, Metal is not cracked, bent or dented, mirrors are clean, clear not cracked, loose or

missing, no missing nuts or bolts. Securely Mounted

Battery: Battery is not corroded, loose, cracked or leaking, wires are not cut, exposed, loose. Batteries

are securely mounted.

Fuel tank(s)/

DEF tanks: Fuel Tank is secured with 2 metal straps, they’re not twisted or loose, rusted through, bushings

are not missing, metal is not rubbing on metal. Gas cap seal is in pace, not worn through,

missing or leaking. I’d look for leaks at the top of fuel tank, at the cap and below the tank, Tank

is securely mounted.

DEF tanks: Def Tank is not twisted or loose, DEF cap and seal is in pace, not worn through, missing or

leaking. I’d look for leaks at the top of DEF tank, at the blue cap and below the tank, DEF Tank

is securely mounted.

Frame(s): Frame is straight; no illegal welds, not twisted or sagging, cracked, bend, dented or rusted

through; cross members are straight, no gaps, missing nuts or bolts or rusted through. Frame

and cross members securely mounted.

(Remember to latch the hood.)

5

Could Ask questions about the Rear Axles

Rear Tires: Rear Tires (duels tires) can be recapped, tread depth is not worn dangerously thin, it’s at least

2/32inchdeep,evenlyworn,noatspots,sidewalls,arenotcrackedwornthrough

or leaking. Budd Spacing Check for even spacing between wheels; no gap between rims, tires

nottouchingorrubbing;noforeignobjectstocauseapunctureorre.

Duel tires arethesametypeandsize.I’dcheckforproperinationatvalvestemsandwithan

airgauge.Tiresareproperlyinated,nomissingdustcapsandaresecurelymounted.

Combination Vehicles (ONLY)

(TRACTOR) Air and Electric connectors and lines, Electrical cord plugged in and secured w/safety latch,

lines are not Cut, Exposed or Loose wires, and enough slack for the turn of trailer. Air lines connected at

glad hands, rubber seal is not torn or leaking and the lines have enough slack for turns.

(SEMI_TRAILER) Air and electric connectors, Electricalcordrmlypluggedinandsecured,notcut,no

corroded exposed or Loose wires, not dragging below the trailer frame. Securely Mounted. Air lines properly

connected, no air leaks, no tears or cuts and not dragging below the trailer frame. Securely Mounted.

Fifth Wheel Skid Plate or Pintle Hook or Tow Hitch

Fifth Wheel 5th Wheel Skid Plate Not Greased, in place of grease is a (poly plate) mounted secured, no

cracks. Not bent or warped. Securely Mounted.

MOUNTING BOLTS Nuts and bolts are not loose or missing, no gaps between platform, bracket and frame,

no loose, cracked bolts or missing nuts and bolts. All Securely Mounted

PLATFORM Secured to frame, not Cracked, Bent and Dented or rusted trough, no missing bolts and nuts.

Securely Mounted.

King Pin & Apron & Gap or Drawbar ring & Tongue

KINGPIN Locked in locking jaws, not Cracked, Bent, or Dented. Head is visible under the locking jaws.

APRON Not cracked, bent or dented, secured to trailer frame. No missing or broken welds.

GAP Look for gaps between the apron and 5th wheel, should be no gap. If there was a gap it would indicate

the kingpin is not properly locked or locking jaw is on the head of the kingpin where it cannot be.

The locking jaw is around the neck of kingpin exactly where it should be. The trailer is securely connected.

Locking & Safety Devices

LOCKING JAWS Locking jaw is around the “shank”, and not the “head” of the kingpin, latched secured and

visible. Not bent or cracked. Properly greased. Securely Mounted

RELEASE ARM properly seated in drive position and safety latch/lock engaged and secured, no cracks

or bent arm. Proper spring tension. If equipped with a Latch, These have safety latch or arm -mention not

missing safety pin and cotter key. Securely Mounted

Trailer Only

Landing gear: Fullyraisedupoground;nomissingwelds,bracketsarenotcracked,bent,dentedorrusted

through. No loose or missing bolts, Handle in stowed in drive potion. Securely Mounted and

strong enough for cargo.

Lenses & Reectors

Reective Tape: Reective tape, is DOT approved tape, clean and clear, covers 50% of the trailer side and

100% at the rear of trailer.

6

Section 11M – Basic Control Skills Page 11M-1

Version: September 9, 2022

Section 11M

Basic Control Skills Test

This Section Covers

• Basic Control Skills Test Scoring

• Basic Control Skills Test Exercises

For the Basic Control Skills test, you will

demonstrate basic skills in controlling a

commercial vehicle and judging its position in

relation to other objects.

It tests for the basic skills needed for safe control

and operation of the vehicle. The types of

judgment and skills required for these basic control

skills are also required in many different driving

situations.

You will receive points for changing direction to

gain a better position, crossing over or touching

boundary lines or cones and for your final position.

You may be permitted to exit the vehicle to check

around the vehicle during backing exercises. When

entering/exiting the vehicle, you must set your

parking brake, place the vehicle in neutral, and

safely exit/enter by facing the vehicle and

maintaining three (3) points of contact at all times

(when entering/exiting a bus, face forward and

maintain a firm grasp on the handrail).

If at any time you open the door, move from a

seated position when in physical control of the

vehicle, (or on a bus, walk to the back to get a

better view), you will be scored for a look.

You will receive specific instructions for each

exercise prior to performing them. You will have an

opportunity to ask questions. You must complete

the exercise as directed. If you see the examiner

raise their hand (like this ), stop and return your

vehicle within the exercise boundary lines.

Your Basic Control Skills test will include the

following exercises, either off-road or somewhere

on the street during the Road Test:

Step 1 – Forward Stop,

Step 2 – Straight-Line Backing,

Step 3 – Forward Offset Tracking, and

Step 4 – Reverse Offset Backing.

These exercises are shown in Figures 12M.1

through 12M.4 on page 12M-4.

11M.1 Scoring

During the Basic Control Skills test exercises, you

will be scored for:

Pull-ups – pulling forward on a backing exercise to

clear an encroachment or to get a better position is

scored as a “pull-up.” These exercises include

Exercise 2 – Straight-Line Backing and Exercise

4 – Reverse Offset Backing. The examiner will

score the number of times you pull-up.

Stopping without changing direction does not count

as a pull-up.

You will not be penalized for initial pull-ups.

However, an excessive number of pull-ups, will

count as errors. Your examiner will cover “pull-ups”

when giving instructions for these exercises.

Back-ups – backing up on a forward moving

exercise to clear an encroachment or to get a

better position is scored as a “back-up.” “Back-ups”

will be scored on Exercise 3 – Forward Offset

Tracking. The examiner will score the number of

times you back-up.

Encroachments – crossing over or touching

exercise boundary lines or cones with any portion

of your vehicle, other than the vehicle’s mirrors

(door or fender) or other unique vehicle parts at

door mirror height or higher, such as a bucket

truck, is scored as an encroachment. Unique parts

below door mirror height are counted as an

“encroachment.”

If you have encroached, the examiner will stop you

and you must return the vehicle within the exercise

boundaries. You must stop immediately when

signaled by the examiner. The examiner will score

the number of times you touch or cross over an

exercise boundary line or cone. Each

encroachment will count as an error.

Looks – exiting the vehicle while performing an

exercise to check the vehicle’s position while

backing. You may be permitted to safely stop and

exit the vehicle to check the external position of the

vehicle (look).

When doing so, you must set the parking brake(s)

and place the vehicle in neutral. Then, when

exiting/entering the vehicle, you must do so safely

by facing the vehicle and maintaining three (3)

points of contact with the vehicle at all times (when

exiting/entering a bus, you may face forward and

maintain a firm grasp on the handrail). If you do not

safely secure the vehicle or safely exit/enter the

vehicle, it may result in an automatic failure for an

unsafe act.

If you open your door or move from a seated

position, it will count as a "look.” If you open your

door while the vehicle is moving (not in neutral and

park), it may result in an automatic failure for an

unsafe act.

On a bus, if you walk to the back of the bus to get

a better view, it will count as a “look.”

You may be allowed a maximum of one (1) free

look on Exercise 2 – Straight-line Backing, and two

(2) free looks on Exercise 4 – Reverse Offset

Backing, to check the position of your vehicle. Your

7

Section 11M – Basic Control Skills Page 11M-2

Version: September 9, 2022

examiner will cover “looks” when giving instructions

for these exercises.

Final Position – the final position of the vehicle for

backing exercises. You will be scored for final

vehicle position on Exercise 2 – Straight-Line

Backing and on Exercise 4 – Reverse Offset

Backing.

It is important that you finish each exercise exactly

as the examiner has instructed. Your vehicle must

be within final exercise boundaries (other than

mirrors and unique vehicle parts higher than the

door mirrors, such as a bucket truck). If you do not

maneuver the vehicle into its final position as

described by the examiner, you will be penalized

and will fail the Basic Control Skills test. You

MUST complete the exercises as directed.

Failure to Follow Instructions or Unsafe Act –

Failure to follow examiner instructions for

completing the exercise as directed may result in

an automatic failure and the test may be

terminated by the examiner. Always follow the

examiner instructions and directions. If you do not

understand the instructions or understand how to

complete the exercises, ask the examiner for

clarification. [If permitted, you may ask the

examiner to walk you through the exercise area.]

Committing an “unsafe act” (e.g., forgetting to set

the parking brake or opening the door while in

motion), may result in an automatic failure for an

unsafe act and the test may be terminated by the

examiner. Safety of the driver, the examiner and

the testing area is of the highest priority. Always

think SAFETY.

11M.2 Exercises

11M.2.1

Exercise 1 – Forward Stop

You will demonstrate your ability to judge the front

of your vehicle during a controlled stop. Drive

forward through the alley and stop with the front

most part of the vehicle (other than unique vehicle

parts higher than the door mirrors, such as a

bucket truck) within the box at the end of the alley

without going past it. You may stop only once.

Your examiner will point out the front most part of

your vehicle when giving instructions for this

exercise.

When you have stopped, set your parking brake,

shift to neural and sound the horn. The examiner

will then score the exercise. You will receive points

if the front most part of the vehicle (other than

unique vehicle parts higher than the door mirrors,

such as a bucket truck) is not in the stop box. (See

Figure 12M.1 on page 12M-4).

11M.2.2

Exercise 2 – Straight Line Backing

You will demonstrate your ability to back a vehicle

in a straight line. From your stopped position from

the previous exercise, the examiner will ask you to

pull forward and stop when they raise their hand

(like this ).

Then back straight through the alley until the front

of your vehicle has cleared the last set of cones at

the far end of the alley. (See Figure 12M.2 on page

12M-4)

You will be scored for pull-ups, encroachments and

final position.

You are allowed one (1) free pull-up and may

safely exit the vehicle only one (1) time to check

around the vehicle.

When you have completed the exercise, set your

parking brake, shift to neutral and sound your horn.

This will inform the examiner you have completed

the exercise and allow them to score your final

position.

11M.2.3

Exercise 3 – Forward Offset Tracking

You will demonstrate your ability to maneuver a

vehicle around other objects while moving forward.

You will drive forward and steer to the left through

the opening into the opposite lane,

keeping the right most rear tire

between the cone and the line.

You will be scored for back-ups, encroachments

and forward tracking clearance (rear tire between

the cone and the line).

There are NO free back-ups, and you are NOT

permitted to exit the vehicle during this exercise.

Stop your vehicle when you are parallel to the

outer boundary, prior to or at the cones at the far

end of the exercise. Then, set your parking brake,

shift to neutral and sound your horn. This will

inform the examiner you have completed the

exercise and allow them to score the exercise.

(See Figure 12M.3 on page 12M-4)

8

Section 11M – Basic Control Skills Page 11M-3

Version: September 9, 2022

11M.2.4

Exercise 4 – Reverse Offset Backing

You will demonstrate your ability to offset back and

park a vehicle at the end of an alley. Starting

parallel with the outer boundary, offset back into

the alley, bringing the rear most part of your

vehicle (other than unique vehicle parts higher

than the door mirrors, such as a bucket truck)

within three (3) feet of the rear of the alley.

Stop with the rear most

part of the vehicle

(other than unique

vehicle parts)

in the three (3) foot box

at the end of the alley.

Your examiner will point out the rear most part of

your vehicle when giving instructions for this

exercise.

Your vehicle must be straight within the alley when

completed. Your vehicle must be completely within

the defined exercise boundaries when completed

(other than mirrors or other unique vehicle parts

higher than the door mirrors, such as a bucket

truck). You may not go beyond the outer boundary

line. (See Figure 12M.4 on page 12M-4)

You will be scored for pull-ups, encroachments and

final position.

You are allowed two (2) free pull-ups and may exit

the vehicle a maximum of two (2) times to check

around the vehicle during this exercise.

When you have completed the exercise, set your

parking brake, shift to neutral and sound your horn.

This will inform the examiner you have completed

the exercise and allow them to score your final

position.

Remember, the Basic Control Skills test must be

passed before you can proceed to the Road Test.

9

Section 11M – Basic Control Skills Page 11M-4

Version: September 9, 2022

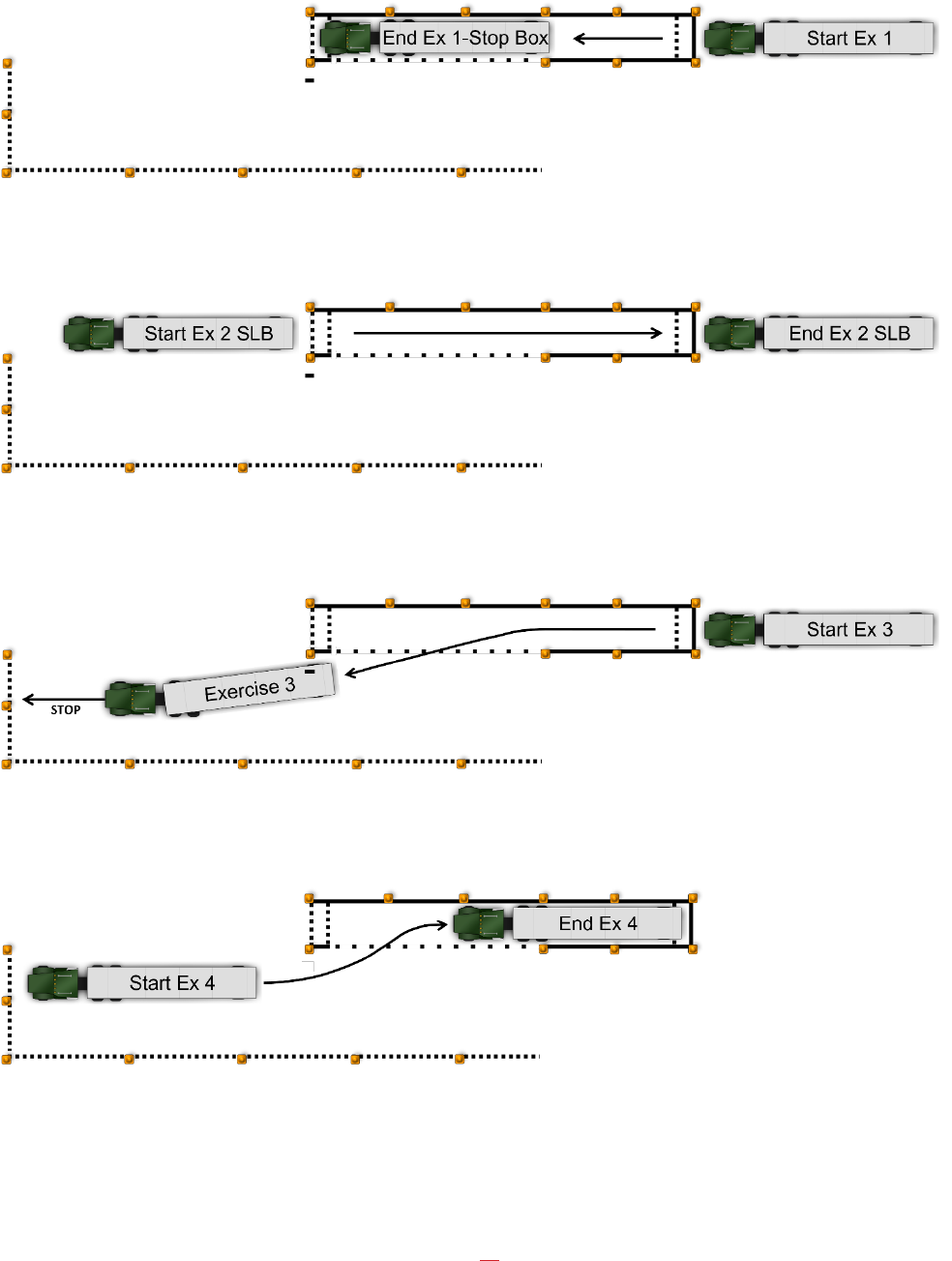

Figure 11M.1: Exercise 1 – Forward Stop

Figure 11M.2: Exercise 2 – Straight Line Backing

Figure 11M.3: Exercise 3 – Forward Offset Tracking

Figure 11M.4: Exercise 4 – Reverse Offset Backing

10

MENTALLY PREPARE FOR YOUR ROAD TEST

Proper Turns: During turns, remember to stay straight and turn late, to make wide enough turns

and to ensure either the drive tire wheels (if class B) and/or trailer wheels do not get too close, rub

or hit a curb. Remember these steps: The closer you are to the right-hand curb the further straight

you have to travel forward to avoid hitting the curb. Be aware of the left and right-hand sides of

your vehicle/s while making turns. Allowing too much space between you and the curb will also

create enough space for drivers to attempt to pass your commercial vehicle, putting you and

other drivers at risk of an accident. Close this gap, meaning; do not make turns too wide so as to

create enough space for dangerous/risky drivers to pass your vehicle on either right and/or left

while completing turns.

Right turns: The truck and trailer tires should be 3-4 feet from the curb, when you start the turn.

And then return to the curb about 3-4 feet to complete the right turn. It’s okay to enter into the

opposinglaneoftracaslongasit’ssafetodoso.It’salsookaytocrossoverthecenterofroad,

center-line/s on right hand turn. Watch your rear wheel / rear trailer wheels in passenger side

mirror, wait for the furthest rear wheel on your commercial vehicle/s setup to enter into the round

portion of the curb and then come back to the curb on your right. DO NOT hit a curb with the

drive tires (if Class B) and trailer tires (if Class A) on any right turn.

Left turns: The truck and trailer must remain in the left most lane, tires must go around the center

lineand/orpaintedyellowcenterlines.Alwaysnishtheturninthesamelaneyoustartedfrom.

DO NOT let the trailer or class B vehicle rears tires cut or cross the yellow the center line/s on a

left turn.

Double Left turns: As a commercial driver you need to turn from the outside lane whenever 2 turn

lanesareavailable.Thus,leavingtheinsidelaneforothertrac.Remembertoreturntothesame

lane you started your left turn from i.e. outside lane to outside lane.

Proper Stops: Come to a complete stop, behind the stop sign 2-3 feet, cross-walks and stop

bars. You should be able to see the bottom edge of the road marking. Remember to stop, look

in both directions and then move when it is safe to do so. You do not want to stop or slow other

drivers down while you proceed through the intersection and/or to complete any turns.

Proper Observation: Be alert and aware of all sides of your commercial vehicle and trailer.

Establish a cushion of space around you and other drivers. Don’t allow your mind to drift into

thought, be present and focused on driving. Keep your head moving during the road test, you can

never look too-much but you can look too-little. Remain focused and observant at all controlled

and uncontrolled intersections, backing & performing lane changes. Move head shoulder to

shoulder. Learn to turn your head and use the windows on the doors not just the window in front

of you.

Proper Hill Park: Always signal to the curb. The truck and trailer if equipped with a trailer

must be parallel to the curb and also 1 foot or less from the curb. Try not to rub the curb

with either the truck or trailer tires. When parking uphill move the tires to the left or away

from the curb. Whenever parking down hill move the tires right or into the curb.

11

Class A Leasing

Oce Address

8899 Hastings St. NE

Blaine, MN 55449

Arden Hills

Exam Station Address

5400 Old Highway 8

Arden Hills, MN 55112

Plymouth

Exam Station Address

2455 Fernbrook Lane N

Plymouth, MN 55442

CDL Appointments for Plymouth and Arden Hills: 651-297-5029

Contacts: Main Line (612)723-4398

Eric / Owner (612)618-1812 | Sabrina (763)344-3113

Brannon (651)802-5063

Proper Highway Driving: Remember to signal early, often and continuous when entering

the highway/freeway. Proper lane changes require you signal early, look, assess and then

move into the lane when it is safe to do so. Commercial drivers should allow a cushion of

space around their vehicle/s. Always have an out or escape plan. Do not follow too close

provide a minimum of 150 feet in the front of the truck. Observe all speed limits, do not

speed.

Backing: Once Truck is in the reverse gear be sure and check both mirrors at least 2-3

times before moving on any of the backing exercises.

Class A Drivers: Should remember the following. Always steer the steering wheel at “a

problem” to avoid “the problem.”

Class B Drivers steer away from the problem to avoid the problem.

Backing exercises are considered extremely risky and potentially dangerous. Always

proceed with caution. Failure to observed both sides of your vehicle is perceived as a risk

to you and others. Always proceed with caution, and look-look, and look again to avoid

risk, issues and failure.

While Driving outside the course the Examiner May Ask Questions: Be prepared to answer

questions about driving scenarios such as, Road signs, Rail Road Crossings, and bridge

Clearances.

READ MN CDL MANUAL SECTION 12 PAGES 214 - 216

Truck – Trailer Rental

Class A or Class B CDL Road Test

www.classAleasing.com

(612) 723-4398

CLASS

LEASING

MINNESOTA TRUCK & TRAILER SCHOOL

A

12

REMINDERS & HELPFUL TIPS

1. You’re not actually checking uid levels, landing gear pins, glad-hands, gas cap & seals,

removing oil and automatic transmission uid dip sticks, coupling and uncoupling of trailer,

crawling under the trailer, pulling release arm so as to unlock the locking jaw of the trailer.

But rather mention this is what I “WOULD DO.”

2.

Make sure you point at the part and give a detailed description/explanation about

every item listed!

MENTION 3-4 things about it, Check it o and move on.

BE detailed but not so detailed that you run out of time, you have 45 minutes to complete

the Pre-Trip portion of the exam.

In short, try to give a 3 - 4 point description about nearly

every item listed.

Examples” - “not cracked, broken, or loose”

- “no missing bolts; mounted securely”

- “not bent, twisted, or warped; not rusted through”

- “not leaking” etc.

Follow the list, and Be mindful of what you are saying and Your time.

3. Study your Pre-Trip. In addition to the presentations, reading this document and watching

the pre-trip videos. You’ll also need to practice, rehearse and study the Pre-Trip on your

own to establish knowledge, condence and passable results.

4. Ask your examiner for a time check throughout the pre-trip exam, examiners are not

responsible to keep you on track. Aim for 10-12 minutes per box.

5.

Arrive at the Driver’s Exam Station at least 30-45 minutes, before your scheduled road

test. And dress and prepare for the inclement weather, cold, rain, snow and ice.

Check in at the Outside Dispatch Window. DO NOT check in at the front door. Instead

walk around the DMV building to the dispatch window.

Wait in or by your CDL Test Truck.

HELPFUL ACRONYMS:

CBD = No Cracks, Bends, Dented ABC = No Abrasions, Bulges, Cracks/Cuts

CDL = No Cracks/Cuts, Dents, Leaks/Loose PMS = Properly Mounted, Secure

CEL = No Corroded, Exposed or Loose wires CCC = Clean, Clear, not Cracked