1

OWNERS AND SERVICE MANUAL

INNOVATIVE CONCEPTS IN ENTERTAINMENT INC.

10123 MAIN STREET, CLARENCE, NY 14031

SERVICE: 1-716-759-0360

FAX: 1-716-759-0884

E-MAIL: [email protected]

WEBSITE: www.icegame.com

2

INTRODUCTION………………………………………...PAGE 3

• GAME FEATURES

• GAME PLAY

SET-UP / TESTING / MAINTENANCE………………..PAGE 4 - 12

• SAFETY PRECAUTIONS

• GAME SET-UP

• ASSEMBLY

• TESTING

• CLEANING

• MANUAL SETTINGS

• AUTO % SETTINGS

• CLAW SHAPE

PROGRAMMING…………………….…SEE INCLUDED BOOKLET

• GAME OPTIONS

PROGRAMMING………………………………………..PAGE 13

• TEST MODE

• ERROR CODES

• ACCOUNTING MODE

QUICK TROUBLESHOOTING…………………………PAGE 14 - 15

• PROBLEMS AND SOLUTIONS

GAME REPAIR…………………………………………..PAGE 16 - 19

• GLASS REPLACEMENT

• MECHANICAL REPAIR

• ELECTRICAL / ELECTRONIC REPAIR

PARTS LISTINGS……………………………………….PAGE 20

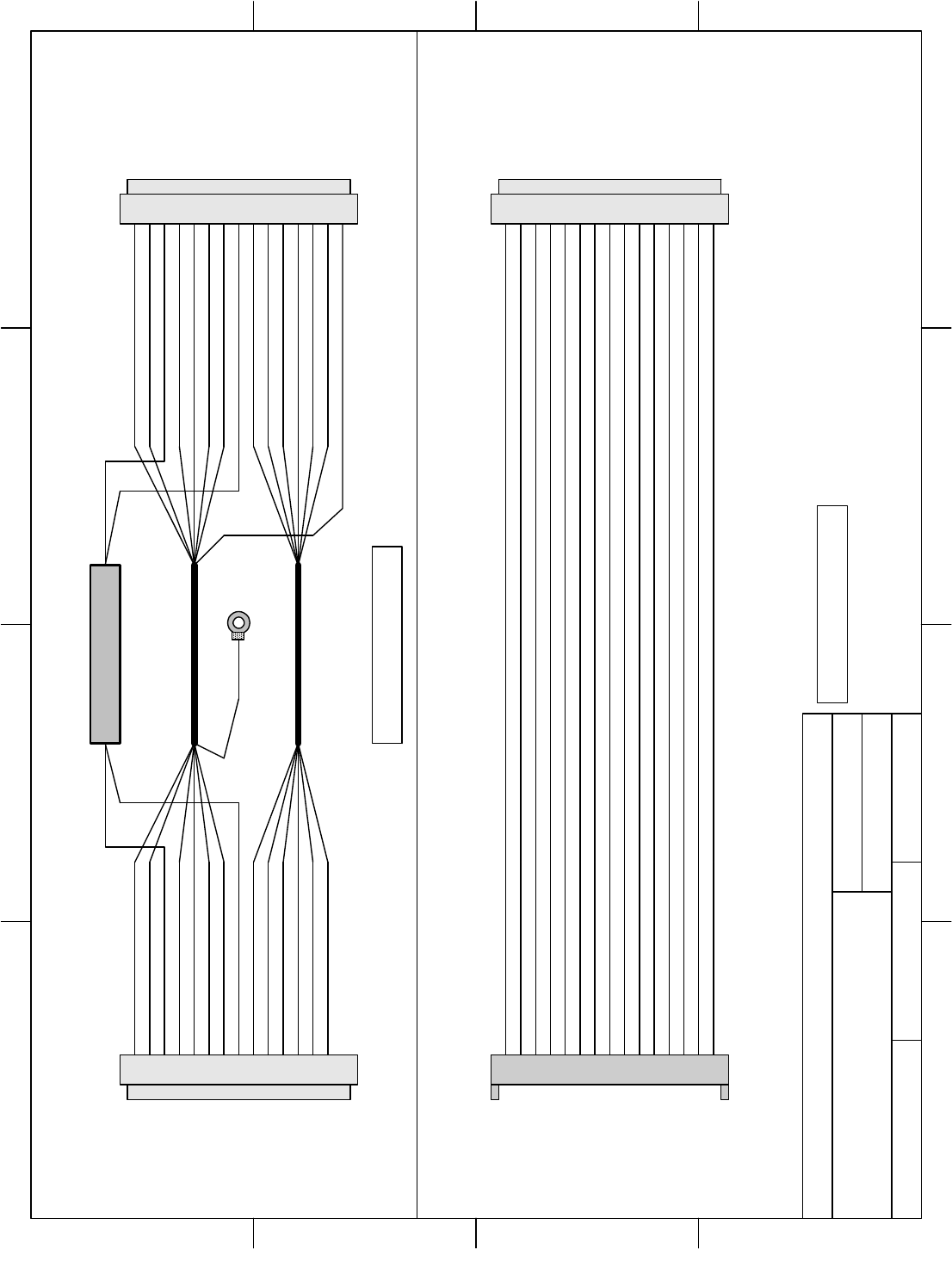

CRANE ASSEMBLY DIAGRAMS……………………...PAGE 21 - 24

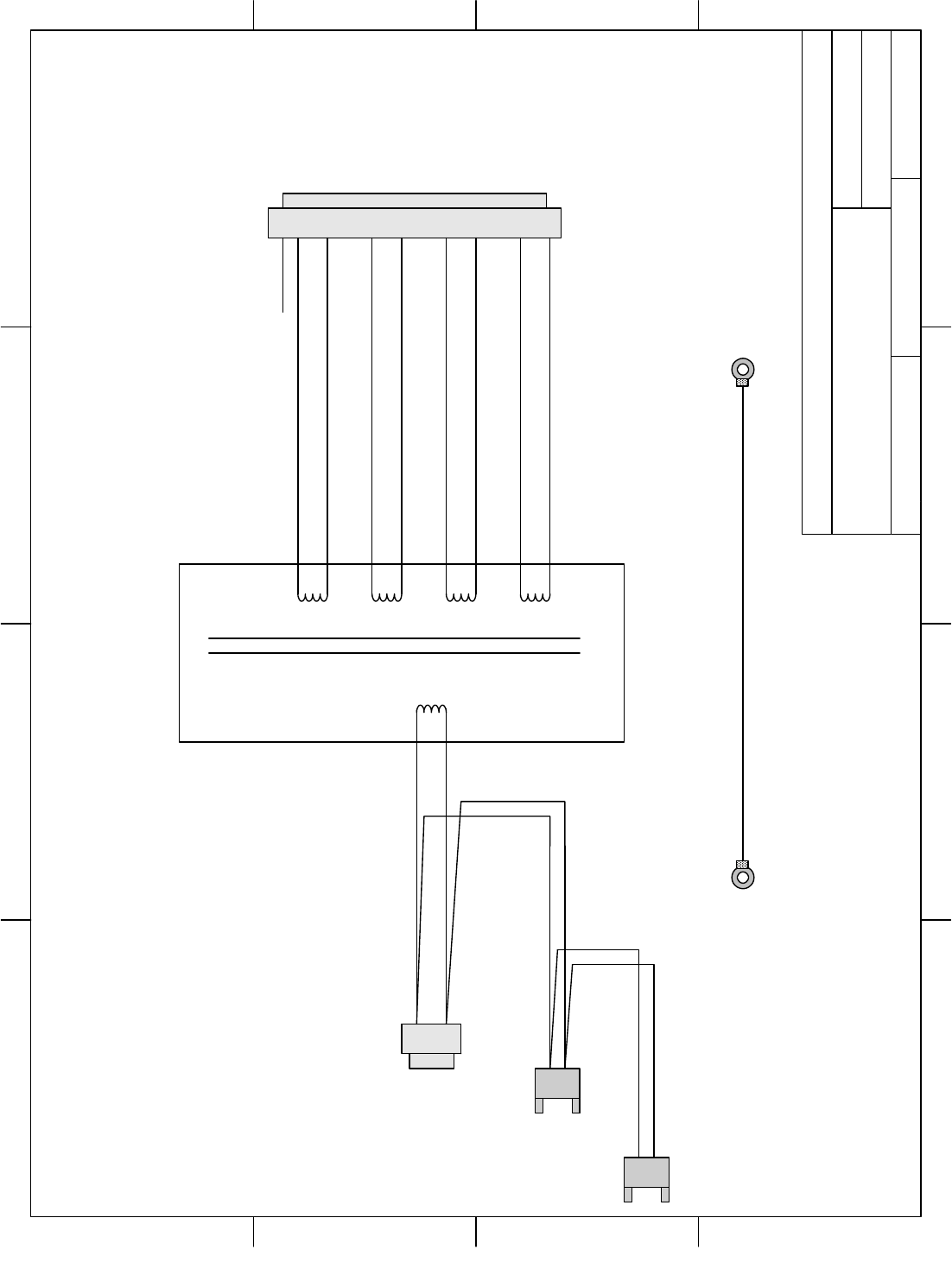

SCHEMATICS / WIRING DIAGRAMS………………...PAGE 25 - 43

WARRANTY INFORMATION…………………………..PAGE 44 - 45

ICEDOC BC9001

REVISION D

1-07-08

TABLE OF CONTENTS

3

INTRODUCTION

GAME FEATURES

Thank you for your purchase of the new PINNACLE

CRANE™ game from I.C.E.

The brand new PINNACLE CRANE™ all metal

crane game by I.C.E. was designed with the

operator in mind. Reliability, low maintenance,

themed cabinetry, and all metal construction are the

key design features, exactly what is needed to

ensure a combination of long life and profit.

With nearly the entire construction made of metal, it

was only natural to Powder Epoxy Coat everything,

inside and out. This provides the owner – operator

with a game that will certainly outlast its wooden

counterparts. A few of the major advantages of all

metal construction include:

- Vault like security

- Long service life

- Low maintenance

- High Durability

All windows, of the PINNACLE CRANE™, are ¼”

tempered glass to provide an easy clean, maximum

safety, scratch resistant surface. Other features

include, 40 strand conductor cables to prevent wire

fatigue, full range of operator adjustable software,

and a newly designed crane mechanism.

The first step in I.C.E.’s new crane design was to

select several leading cranes available on the

market today, observe and determine what problems

can be or are causes of failure and costly down time.

I.C.E. then surveyed operators nation wide,

requesting information like:

- What are the leading causes of crane

failures in your locations

- What are some problems in servicing

cranes

- What changes would you make to current

cranes to create a better machine

I.C.E.’s engineers then compiled all critical data,

addressed and corrected each problem and used

this information to create what we call the

PINNACLE CRANE™.

This method of design ensures that the needs and

concerns of the owner-operators dictate the final

design parameters, for who knows a crane’s

attributes and faults better than a crane operator.

GAME PLAY

As coins are inserted into the PINNACLE CRANE™

all metal game, a customized music is heard. When

sufficient coins have been inserted, the claw clicks

closed and re-opens, which signals the start of the

game. The crane will then position itself in the

middle of the “play field” and remain there, until the

player is ready.

When the player has moved the joystick or pressed

the buttons to move the crane, the timer on the right

display will begin to count down. The player will then

position the crane above the prize they are

attempting to win and press the drop button to lower

the claw.

If the nudging option is on, then the player will have

the ability to keep “nudging” the claw each time the

button is pressed to home-in on the chosen prize. If

the nudging option is off, then the player will have

only one chanceto drop the claw.

When the claw has fully dropped, it will close and

retract to its uppermost position. The crane will then

automatically position itself over the prize chute at

the rear of the cabinet. The claw will then open,

releasing the prize into the prize chamber. The

player can now remove the prize from the chamber

through the prize door located in the front, lower left

corner of the game. The game is now at its home

position and is ready for the next player in line.

If you have any questions regarding Programming,

Troubleshooting or Repair, please call our Service

Department.

I.C.E. Parts/Service Dept.

Phone #: (716) - 759 – 0360

Fax #: (716) – 759 – 0884

NORMAL BUSINESS HOURS ARE:

MONDAY - FRIDAY, 9:00 AM TO 6:00 PM EST

* The crane will remain in the home position if the game type (option 0) is set to 2, 3 or 4. In these options the player may have only two buttons, one

for right travel and one for forward travel. The crane will remain in the home position to allow the player access to the entire play field.

4

SETUP / TESTING / MAINTENANCE

SAFETY PRECAUTIONS

IMPORTANT: FAILURE TO FOLLOW THESE

DIRECTIONS CLOSELY COULD CAUSE SERIOUS

DAMAGE TO YOUR GAME.

WARNING: WHEN INSTALLING THIS GAME, A

3-PRONG GROUNDED RECEPTACLE MUST BE

USED. FAILURE TO DO SO COULD RESULT IN

SERIOUS INJURY TO YOURSELF OR OTHERS.

FAILURE TO USE A GROUNDED RECEPTACLE

COULD ALSO CAUSE IMPROPER GAME

OPERATION, OR DAMAGE TO THE

ELECTRONICS.

DO NOT DEFEAT OR REMOVE THE GROUNDING

PRONG ON THE POWER CORD FOR THE SAME

REASONS AS GIVEN ABOVE. USING AN

IMPROPERLY GROUNDED GAME COULD VOID

YOUR WARRANTY.

GAME SET-UP

BEFORE PLUGGING THE GAME IN, OR TURNING

IT ON, BE SURE THE GAME HAS BEEN SET TO

THE PROPER VOLTAGE. YOUR GAME SHOULD

COME PRE-SET FROM THE FACTORY

CORRECT VOLTAGE, HOWEVER IT IS A GOOD

IDEA TO CHECK THE A.C. WALL RECEPTACLE

VOLTAGE BEFORE PLUGGING THE GAME IN.

ASSEMBLY INSTRUCTIONS

1. Carefully unbox the game from its packaging.

2. Using the supplied keys, unlock the front door of

the cabinet.

3. Cut all tie wraps holding the wagon assembly

and crane in place.

4. Plug the game into a three prong grounded

receptacle. NOTE:

The appliance must be

positioned such that the plug is accessable

during use.

5. The game is now ready for start up.

TESTING

After the initial setup, it is time to test your game for

proper operation.

1. Locate the game in its permanent location and

lock all casters.

2. Be sure the game has been properly plugged

into a 3-prong grounded outlet, and that the

receptacle is in good working order.

3. If using an extension cord, be sure it is a 3-prong

grounded type of at least 16Ga.

4. Verify that the game is set up for the proper

voltage, and turn the power to the game on.

5. The game will run through a test mode at every

startup. (See test mode explanation in the

programming section for details.)

6. Insert coins/bills into the machine at least ten

times into the coin mech/bill acceptor to ensure

proper operation.

7. Check the credit and prize counters for proper

operation.

8. Check that the door disconnect switch works

properly.

9. Check game volume during busy time at location

to set it at the proper level.

CLEANING

Regular cleaning of this game will keep it looking

new, and greatly enhance its appeal.

Clean the windows of your PINNACLE CRANE™

with a standard window cleaner such as “Windex”®.

Clean the cabinet sides with a good cleaner such as

“Fantastik”® or “409”® and a soft rag. A mild soapy

solution can also be used.

NOTE: DO NOT USE ALCOHOL, THINNERS OF

ANY KIND, OR PINBALL PLAY FIELD CLEANERS

ON ANY OF THE CABINET SURFACES

ESPECIALLY THE DECALS.

IF YOU HAVE ANY QUESTIONS OR COMMENTS

REGARDING INSTALLATION OR PROPER

FUNCTION OF YOUR GAME, PLEASE CALL OUR

SERVICE DEPARTMENT AT (716)-759-0360

5

SETUP / TESTING / MAINTENANCE

MANUAL SETTING

Initial adjustment tips

− It is important to know that a mechanical adjustment is considered a “Macro adjustment” or a large adjust-

ment, and that a software adjustment is considered a “Micro adjustment” or a fine adjustment.

−

NOTE: These adjustments need only be performed when setting up the crane for the first time or when

major changes to plush size and/or shape occur. Once a configuration is determined for your particular

requirements, the same configuration in another CRANE GAME may require only minor adjustments.

−

It is advisable that you position your plush such that the “Eyes” are facing forward and looking at your po-

tential customers.

−

To maintain proper payout in either Manual mode or Skill leveling mode, ALL plush in the crane should be

of similar size, shape and weight. DO NOT attempt to use 6” plush with 14” plush in the same crane as

you are likely to have very different payout % from week to week which requires constant monitoring and

adjusting.

−

Set option 0 (Game mode) for game type you desire.

−

Set option 3 (Game cost) for you particular game.

−

For the following tests, make sure that option 9 (Skill leveling strength) is set to 00. Any setting other than

00 and Skill leveling is enabled and incorrect results may occur.

−

Make sure that the claw tips, when closed, are just touching. DO NOT allow them to overlap, for the claw

could mechanically bind, causing down time.

−

CHECK IF YOU HAVE THE CORRECT CLAW SHAPE. Assuming you have a medium claw, standard on

most cranes, set option 8 to 40, 9 to 00 and play the game approximately 25 times. At this level, you

should have difficulty picking up plush.

−

If you are able to pick up plush rather easy, you have the wrong claw shape or size and should go

to the end of this section and see CLAW SHAPE.

−

If you are unable to pick up plush, then set option 8 to 99 and play 25 games. You should now be

able to pick up plush fairly consistently. If this is true, continue on to the next step. NOTE: When

the game is first packed, it is often difficult to pick up plush until an area is cleared to maneuver in.

Take this in to account while determining if the claw size or shape is correct.

−

Initially set option 8 (Manual strength) based on your plush size, such that the claw is just able to hold the

plush when closed. If you are unsure, a good starting point for option 8 is 60 for average size plush and

our standard medium claw. NOTE:

When in programming mode at option 8, the claw will begin the open

and close at approximately 5 second intervals. The operator can then associate the claw strength number

on the right display with an actual “physical” claw strength at the claw.

−

Knowing the cost of a game, the average cost of a piece of plush and the desired payout %, calculate the

proper plush dispensing intervals for your setup, using the following formula:

6

SETUP / TESTING / MAINTENANCE

Calculation Option 1

1) 100 * (Game cost) = A (# of dollars received for 100 games)

2) A * (Desired payout %) = B (# of dollars worth of plush that should be dispensed in 100 games)

3) B / (Cost of plush) = C (# of pieces of plush that should be dispensed in 100 games)

4) 100 / C = Y (Proper plush dispensing intervals)

OR

Calculation Option 2

1) (Plush Cost) / (Game Cost) = X (# of games required to pay for one piece of plush)

2) (X) / (Desired Payout %) = Y (Proper plush dispensing interval)

EXAMPLE

Game cost = $0.50

Avg. cost of 1 plush = $2.00

Desired payout % = 33%

Example Calculation Option 1

1) 100 * ($0.50) = $50

2) $50 * (.33) = $16.5 worth of plush in 100 games to give a 33% payout

3) $16.5 / ($2.00) = 8.25 pieces of plush per 100 games to give a 33% payout

4) 100 / (8.25) = 12.12 round off to 12.

OR

Example Calculation Option 2

1) $2.00 / ($0.50) = 4

2) (4) / (.33) = 12.12 round off to 12

NOTE: This means that for approximately every 12th game played, 1 piece of plush should be won.

7

SETUP / TESTING / MAINTENANCE

Armed with the information particular to your game (Proper plush dispensing intervals determined above) play at

least 50 games and see if the correct number of plush have been dispensed. (For the example above, in 50 games

you should have dispensed approximately 4 pieces of plush. (Every 12.12 games) NOTE: The more games you

play during the “TEST”, the more accurate your accounting will be). When 50 games have been played, calculate

the payout % using the formula below:

1) (# of plush dispensed) * (Cost of 1 pc. of plush)

= Payout %

(# of games played) * (Cost of game)

EXAMPLE

Cost of a game = $0.50

Cost of 1 pc. of plush = $2.00

# of plush dispensed = 55

# of games played = 423

(55)* ($2.00)

(423 * ($0.50) = 52 =52% payout

If the calculated payout is very high, your desired payout + 10% or more, it will be necessary to make a macro

adjustment or move the claw tips apart slightly by loosening the three screws holding the claw slider to the

coil housing and moving the claw slider up slightly. (See Fig. 1) NOTE:

MOVING THE CLAW SLIDER 1/8th

OF AN INCH COULD CHANGE YOUR PAYOUT BY AS MUCH AS 40%. BE SURE TO MOVE THE SLIDER

IN VERY SMALL INCREMENTS SO AS NOT TO OVERSHOOT YOUR DESIRED PAYOUT.

If the calculated payout is slightly high, your desired payout + less than 10%, then you can make a

micro adjustment or software claw strength adjustment at Option 8.

Conversely, if the calculated payout is very low or slightly low, you will need to make a macro or micro

adjustment accordingly.

Repeat the 50 games test and calculate the Payout %. Repeat the mechanical adjustment until you

are within 10% of your desired payout. You can now enter the programming mode and adjust Option 8

(Mechanical strength) up or down slightly to achieve your desired payout. Your game is now set up according

to your Desired Payout, Game Cost and Plush Cost.

If after using the initial adjustment tips above, you are still having difficulty in setting up your game, please call

the I.C.E. service line at:

I.C.E. SERVICE DEPARTMENT

716-759-0360

NORMAL BUSINESS HOURS ARE:

MONDAY – FRIDAY, 9:00 AM TO 6:00 PM EST

8

SETUP / TESTING / MAINTENANCE

AUTO STRENGTH SETTINGS

Initial adjustment tips

− Before setting up Auto Percentaging, it is highly advisable to set up Manual Percentaging. This is a pre-

caution in the unlikely event that the prize sensor fails or error code 10 or 11 is logged. If either one of

these situations occurs, the game will AUTOMATICALLY revert to manual percentaging settings, allowing

the game to still function until the error is corrected. If your manual settings are not set up, it may be pos-

sible to dispense too much plush resulting in a loss of revenue for that week, or dispensing too little plush,

causing your customers to feel as though they can not win, which will eventually result in a loss of play

and revenue.

− It is important to know that a mechanical adjustment is considered a “Macro adjustment” or a large adjust-

ment, and that a software adjustment is considered a “Micro adjustment” or a fine adjustment.

− NOTE: When using Auto Percentaging, you will be required to reset the computer memory once a week.

This is done to clear computer memory of “portions” of plush that were to be dispensed and have not

been OR “portions of plush that have not been dispensed and should not have been. Since we are hu-

man, we think of plush as whole entities. The computer has the ability to track plush as pieces or fractions

of pieces. For example: If we want a 34% payout based on $2.00 average cost plush and $0.50 game

play, we want APPROXIMATELY 1 piece of plush dispensed every 12 games. The actual number is 1

piece of plush for every 11.7647 games. The computer from week to week may have a bunch of the little

pieces of plush that it did not give away and will eventually add up and hit the limit of 8 pieces not dis-

pensed and take you out of Skill leveling Mode. Often this confuses an operator since the game worked

very well for several weeks or even longer, but then kicked into Manual Mode and gave them an Error 11.

To prevent this, it is HIGHLY suggested you reset the computer once a week using the following proce-

dure:

− Once a week, or after a minimum of 500 games, enter the programming mode and change the % payout

number up by one number and exit programming mode. The following week, enter the programming mode

and change the % payout number down by one number. Example: Week one, the % payout number = 33.

Week two, change % payout to 34. Week three, change % payout number back to 33, etc. Using % payout

will have the smallest change on payout yet it will reset memory and keep things working as intended.

− NOTE: These adjustments need only be performed when setting up the crane for the first time or when

major changes to plush size and / or shape occur. Once a configuration is determined for your particular

requirements, the same configuration in another CRANE GAME may require only minor adjustments.

− It is advisable that you position your plush such that all “Eyes” are facing forward and looking at your po-

tential customers.

− To maintain proper payout in either Manual Mode or Auto Percentaging Mode, ALL plush in the crane

should be of similar size, shape and weight. DO NOT attempt to use 6” plush with 14” plush in the same

crane as you are likely to have very different payout % from week to week which requires constant moni-

toring and adjusting.

− Set Option 0 (Game mode) for game type you desire

− Set Option 3 (Game cost) for your particular game.

− Make sure that the claw tips, when closed, are just touching.

− To check if you have the correct claw shape, set Option 8 to 50, Option 9 to 00 and play the game ap-

proximately 25 times. At this level, you should have difficulty picking up plush.

9

SETUP / TESTING / MAINTENANCE

− If you are able to pick up plush, you have the wrong claw shape or size and should go to the end of this section

and see CLAW SHAPE

− If you are unable to pick up plush, then set Option 8 to 99 and play 25 games. You should now be able to pick

up plush fairly consistently. If this is true, continue on to the next step. NOTE: When the game is first packed, it

is often difficult to pick up plush until an area is cleared to maneuver in. Take this into account while determin-

ing if the claw size or shape is correct.

− Make sure Option 8 (Manual strength) is et up as detailed above before setting up Skill leveling.

− Determine the proper Minimum Claw Strength by setting Option to 9 initially to 60 on the right display. Notice

that the claw is opening and closing on a 5 second interval. Hold an average size piece of plush in the claw as

it closes and note whether it has enough claw strength to hold the plush. Repeat this procedure until you find

the breaking point where the claw will hold the piece of plush but if you lower the strength of the claw by 1 or 2

points, the claw will no longer be able to old the plush. This will be the number you want to use as your Skill

leveling strength (Option 9). It will allow a skilled player to move plush around and have the ability to win at any

time, yet requires a skilled player to win easily.

− Set Option 16 (Plush cost) based on the cost of your plush.

− Set Option 17 (Desired payout %) based on your desired payout.

− Knowing the cost of a game, cost a piece of plush and the desired payout %, calculate the proper plush dis-

pensing intervals using the following formula:

Calculation Option 1

1) 100 * (Game cost) = A (# of dollars received for 100 games)

2) A * (Desire payout %) = B (# of dollars worth of plush that should have been dispensed in 100

games)

3) B / (Cost of plush) = C (# of pieces of plush that should be dispensed in 100 games)

4) 100 / C = Y (Proper plush dispensing intervals)

OR

Calculation Option 2

1) (Plush Cost) / (Game cost) = X (# of games required to pay for one piece of plush)

2) (X) / (Desired payout %) = Y (Proper plush dispensing interval)

EXAMPLE

Game cost = $0.50

Avg. cost of 1 plush = $2.00

Desired payout % = 33%

Example Calculation Option 1

1) 100 * ($0.50) = $50

2) $50 * (.33) = $16.5 worth of plush in 100 games to give a 33% payout

3) $16.5 / ($2.00) = 8.25 pieces of plush per 100 games to give a 33% payout

4) 100 / (8.25) = 12.12 round off to 12

OR

10

SETUP / TESTING / MAINTENANCE

Example Calculation Option 2

1) $2.00 / ($0.50) = 4

2) (4) / (.33) = 12.12 round off to 12

NOTE:

This means that for approximately every 12th game played, 1 piece of plush should be won.

Armed with the information particular to your game (Proper plush dispensing interval determined above) play

at least 50 games and see if the correct number of plush have been dispensed. (For the example above, in

50 games you should have dispensed approximately 4 pieces of plush. (Every 12.12 games) NOTE: The

more games you play during the “TEST”, the more accurate your accounting will be). When 50 games have

been played, calculate the payout % using the formula below:

1) (# of plush dispensed) * (Cost of 1 pc. Of plush)

= Payout %

(# of games played) * (Cost of game)

EXAMPLE

Cost of a game =$0.50

Cost of 1 pc. Of plush = $2.00

# of plush dispensed = 55

# of games played = 423

(56) * ($2.00)

(423 * ($0.50) = 52 = 52% payout

If the calculated payout is very high, your desired payout + 10% or more, it will be necessary to make a macro

adjustment or move the claw tips apart lightly by loosening the three screws holding the claw slider to the coil

housing and moving the claw slider up slightly. (See Fig. 1) NOTE:

MOVING THE CLAW SLIDER 1/8TH OF

AN INCH COULD CHANGE YOUR PAYOUT BY AS MUCH AS 40%. BE SURE TO MOVE THE SLIDER IN

VERY SMALL INCREMENTS SO AS NOT TO OVERSHOOT YOUR DESIRED PAYOUT.

If the calculated payout is slightly high, your desired payout + less than 10%, then you can make a

micro adjustment or software claw strength adjustment at Option 8.

Conversely, if the calculated payout is very low or slightly low, you will need to make a macro or micro adjust-

ment accordingly.

Repeat the 50 games test and calculate the Payout %. Repeat the mechanical adjustment until you are within

approximately 5 - 10% of your desired payout. You can now enter the programming mode and adjust Option

9 (Skill leveling strength) up or down slightly to achieve your desired payout. Your game is now set up accord-

ing to your Desired Payout, Game Cost and Plush Cost. If at a later date you want to change your game cost,

desired payout, plush cost, etc., it is NOT

necessary to re-adjust your game manually. Just adjust the value

option you wish to change in the PROGRAMMING SECTION. The game will adjust to your new configuration.

If after using the initial adjustment tips above, you are still having difficulty in setting up your game, please call

the I.C.E. service line at 1-716-759-0360.

11

SETUP / TESTING / MAINTENANCE

CLAW SHAPE

In an attempt to satisfy all variables associated with proper payout, I.C.E. has opted to include directions on

how to reshape your medium claw for a lesser and greater mechanical advantage. On the following page are

two medium claw shapes which will give very different mechanical advantages and ultimately very different

claw strengths.

− When Option 8 is set to 50, and you are still picking up plush, then you will need to reshape your 3

claws to look more like shape “A”. (SEE FIG. 2) NOTE: Be sure to align holes in claw with drawn

holes on the template. This will assure proper shaping of the claw.

− When Option 8 is set to 99, and you are unable to pick up plush consistently, then you will need to

reshape your 3 claws to look more like shape “B”. (SEE FIG. 2) NOTE: Be sure to align holes in

claw with drawn holes on the template. This will assure proper shaping of the claw.

These are two claw shapes that I.C.E. has proven to work well, although there are many other shapes that

may work. You will need to remove the claws from the claw mechanism by following the steps listed below.

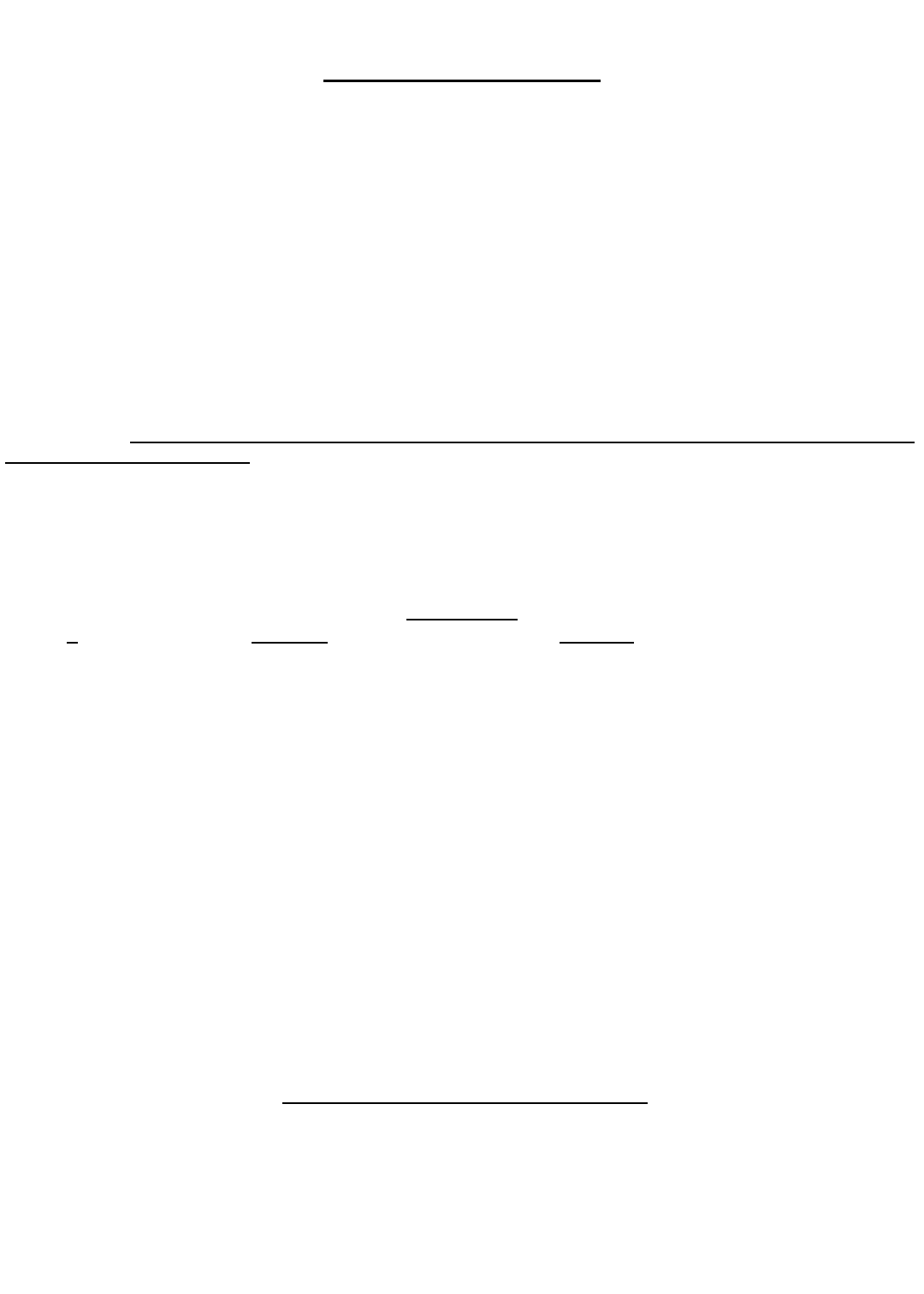

1) Remove the claw mechanism from the coil housing by loosening the three screws on the coil slider

and removing. Be sure not to lose the small spring around the plunger and the black Rynite

washer below the spring. These two parts are critical in the proper operation of the crane mecha-

nism. (SEE FIG. 1)

2) Loosen and remove the six small Phillips head machine screws and Nylock nuts attaching the

three claws to the coil-claw interconnect and coil spider. (SEE FIG.1)

3) Reshape the claws according o the CLAW SHAPE Templates “A” or “B”.

4) Re-assemble in reverse order. Make sure NOT

to over tighten the Nylock nuts attaching the claws

to the mechanism, as this would cause binding.

Now that you have reshaped your claws for your plush, return to the beginning of Adjustment tips and pro-

ceed through each step.

FIG. 1

12

CLAW TEMPLATES

CLAW SHAPE “A”

- DECREASED MECHANICAL ADVANTAGE -

CLAW SHAPE “B”

- INCREASED MECHANICAL ADVANTAGE -

NOTE: THESE ARE THE TWO CLAW SHAPES THAT HAVE BEEN THOROUGHLY TESTED BY I.C.E. AND ARE

PROVEN TO WORK. THEY SHOULD BE USED AS A GUIDE TO INCREASE OR DECREASE THE MECHANICAL

ADVANTAGE OF THE CLAW FOR YOUR PARTICULAR PLUSH. OTHER CLAW SHAPES IN - BETWEEN CLAW

SHAPES A & B MAY WORK BUT WILL REQUIRE FURTHER TESTING.

FIG. 2

13

PROGRAMMING

Test Mode Explanation

Every time that the game is powered up, the door is closed or exiting programming mode, the game will run

through a test mode to check the following items:

- HOME BACK SWITCH - FRONT / BACK MOTOR - PRIZE SENSOR

- HOME LEFT SWITCH - LEFT / RIGHT MOTOR - OUT OF RANGE

- UP SWITCH - CREDIT / COIN DISCONNECT - E² (MEMORY)

- DOWN SWITCH - CLAW CLOSE, CLAW OPEN

If any of the above items are malfunctioning, the game will light up the 4 decimal points on the podium displays.

This will alert the operator that there has been a problem. The operator needs only unlock and open the front door

and the error codes will be displayed one at a time on the left display. To move to the next error code, the operator

needs to press the drop button. Repairs should be made to those areas in which errors have been logged. When

all codes have been seen, and the door is closed, the game will reset the error codes, run through a test mode to

check for proper operation and if all is well, game play can start. If not, the 4 decimals will once again light up and

the operator will need to check the error codes again. Game play can continue to the best of the machine’s abili-

ties, with problems, until the errors are corrected. At no time should the game be inoperable unless a key compo-

nent is damaged.

Error code 10 / 11 will alert the operator that the game has paid out 8 too many or 8 too little pieces of plush when

in skill leveling. If this error is logged, the game will automatically revert to MANUAL settings until one of the follow-

ing options has been changed. (COST OF PLUSH, SKILL % MIN., % PAYOUT, OR GAME COST) This is why it is

imperative that the manual setting be setup before skill leveling is used.

NOTE: Changing one of these options will reset error code 10 / 11 and the game will begin skill leveling with the

new settings.

NOTE: Some items on the list can not be detected by the game and require that the operator watches for these

actions to be performed during the start up test mode. (Claw close, Claw open)

Error Codes

# Problem Solution

1 E² (Memory) Replace Microprocessor

2 Prize Sensor Check / Replace Prize Sensor

3 Up Sensor Check / Replace Up Sensor

4 Down Sensor Check / Replace Down Sensor

5 Left / Right Sensor Check / Replace L /R Sensor

6 Front / Back Sensor Check / Replace F /B Sensor

7 Front / Back Motor Check / Replace F / B Motor

8 Left / Right Motor Check / Replace L / R Motor

9 Front Sensor Check / Replace Front Sensor

10 Counter Disconnect Just a warning that the credit / coin

counters were disconnected at some time.

11 Out Of Range (High) Change setting for the Cost of Plush,

Skill leveling Min, % Payout or Game Cost

12 Out Of Range (Low) Change setting for the Cost of Plush,

Skill leveling Min, % Payout or Game Cost

Entering the Accounting Mode

To enter the accounting mode, unlock and open the front door and press the button marked ACCOUNT, lo-

cated near the main board. The left displays will flash between “cr” (Credits) then the number of credits 1 -

9999. If the operator presses the drop button, the displays will flash “pl” (Plush) then the number of plush that

has passed through the sensor. These numbers can never be reset and WILL NOT match the numbers on

the mechanical counters from the counters. It is advisable that the owner note this difference so that they will

be able to track actual software coins / credits and plush out vs. the mechanical counters for accounting pur-

poses.

14

PROBLEM PROBABLE CAUSE SOLUTION

QUICK TROUBLESHOOTING

THE DECIMALS ON THE 4

DISPLAYS ARE LIT UP

NO GAME POWER

GAME WILL NOT TAKE MONEY

OR GIVE CREDITS CORRECTLY

DISPLAYS DO NOT WORK

CRANE OR WAGON DOES NOT

MOVE

CRANE KEEPS TRYING TO

MOVE IN TO THE HOME

POSITION

CLAW WILL NOT CLOSE

CLAW STAYS CLOSED

SKILL LEVELING IS NOT

FUNCTIONING

CLAW GOES DOWN AND THEN

UP BUT DOES NOT CLOSE

CLAW COMES UP AND ABOUT

10 SEC. PASSES BEFORE

CRANE MOVES TO THE HOME

POSITION

CRANE OR WAGON WHEELS

SLIP

THIS IS IN FACT NOT A PROBLEM BUT A WAY

OF LETTING THE OPERATOR KNOW THAT

THERE WAS A PROBLEM DURING THE START

UP MODE

ON-OFF SWITCH ON THE GAME IS TURNED OFF

BLOWN A.C. POWER FUSE

GAME NOT PLUGGED OR CORD DAMAGED

BAD TRANSFORMER

TRANSFORMER HARNESS NOT CONNECTED

BAD POWER MODULE

BAD COIN SWITCH

COIN DISCOUNTING SET WRONG

COINS PER CREDIT SETTING INCORRECT

BAD COIN MECHANISM

LOOSE OR DAMAGED HARNESSING

BAD MAIN P.C. BOARD

BAD 12V FUSE

BAD DISPLAY P.C. BOARD

BAD MAIN P.C. BOARD

LOOSE OR DAMAGED DISPLAY HARNESSING

BAD MOTOR

LOOSE OR DAMAGED HARNESSING

BAD SWITCH ON BUTTON OR JOYSTICK

BAD HARNESSING TO BUTTONS OR JOYSTICK

BLOWN FUSE TO MOTORS ON MAIN P.C.B.

BAD LIMIT SWITCH(S)

LIMIT SWITCH NOT ALIGNED WITH ACTUATOR

BLOWN FUSE TO CLAW ON MAIN P.C. BOARD

BAD COIL

LOOSE OR DAMAGED HARNESSING

CLAW HAS MECHANICALLY JAMMED

BAD DRIVE TRANSISTOR ON MAIN P.C.B.

CLAW HAS MECHANICALLY LOCKED

PROGRAMMING IS NOT CORRECTLY SET

BAD PRIZE SENSOR

LOOSE OR DAMAGED SENSOR HARNESS

DOWN SWITCH BAD

LOOSE OR DAMAGED HARNESS TO DOWN

SWITCH

UP SWITCH BAD

LOOSE OR DAMAGED HARNESS TO UP SWITCH

BROKEN “UP” SPRINGS

MISSING OR DAMAGED O-RING DRIVE BELTS

LOOSE SET SCREWS IN WHEELS

LOOSE SET SCREWS IN DRIVE COUPLER

RAILS NEED TO BE SCUFFED

OPEN THE FRONT DOOR AND THE

ERROR CODES ARE SHOWN ON THE

DISPLAYS. TO ADVANCE THROUGH

THE ERROR CODES, PRESS THE

FIRE BUTTON

TURN POWER ON

REPLACE WITH PROPER FUSE

CHECK POWER CORD

CHECK FOR PROPER VOLTAGES

CHECK HARNESS

REPLACE POWER MODULE

CHECK W/METER AND REPLACE

CHECK PROGRAMMABLE SETTING

CHECK PROGRAMMABLE SETTING

ADJUST OR REPLACE

CHECK W/METER—REPAIR

REPAIR OR REPLACE MAIN BOARD

REPLACE WITH PROPER FUSE

REPAIR OR REPLACE P.C. BOARD

REPAIR OR REPLACE P.C. BOARD

CHECK W / METER AND REPAIR

REPLACE MOTOR

CHECK W / METER—REPAIR

REPLACE SWITCH

CHECK W / METER—REPAIR

REPLACE WITH PROPER FUSE

REPLACE SWITCH(S)

ALIGN SWITCH AND ACTUATOR

REPLACE WITH PROPER FUSE

REPLACE COIL

CHECK W / METER AND REPAIR

FIND JAM AND REPAIR

REPLACE TRANSISTOR

FIND JAM AND REPAIR

SET OPTIONS “9”, “16” AND “17”

REPLACE PRIZE SENSOR

CHECK W / METER AND REPAIR

REPLACE DOWN SWITCH

CHECK W / METER AND REPLACE

REPLACE UP SWITCH

CHECK W / METER AND REPLACE

REPLACE SPRINGS

REPLACE O-RING BELTS

TIGHTEN SET SCREWS

TIGHTEN SET SCREWS

SCUFF TOP OF RAILS WITH

SANDPAPER

15

QUICK TROUBLESHOOTING

- NOTE: A self test will be performed each time the front door is “closed” , the game is powered up, or when

you exit programming mode.

- NOTE: The game will not count credits or plush out on either the mechanical or software counters while the

front door is open.

- NOTE: If the Wagon does not move smoothly through a full travel from left to right, check to see that the

wheel spacing is correct. If the spacing is correct, then check the 2 cabinet rails for burrs that may cause the

wheels to bind.

- NOTE: If the Crane does not move smoothly through a full travel from front to back, check to see that the

wheel spacing is correct. If the spacing is correct, then check the 2 separator rails for burrs that may cause

the wheels to bind.

- NOTE: If the Micro track for the left / right movement is binding during its travel, check to see if the top mirror

bracket’s edge, also the shelf the micro track rides on, has been de-burred.

- NOTE: If the front door is having trouble closing fully, check to see that all harnessing is out of the way for

the door to close. Next, check to see that the prize chamber wall is far enough to the right to allow the right

edge of the prize door frame to swing past. Finally, check to see that the door is aligned properly.

- NOTE: If the door will not lock properly or locks with difficulty, check to see that the lock rotates smoothly.

Next, check that the lock rods are not binding on the lock cam or the lock rod guides. Next, check that all fric-

tion points have been lubricated with molly grease. Finally, if need be, adjust the lock rod guides such that the

door closes and locks smoothly.

- NOTE: If the decimals light up on the displays after a self test, an error has been logged. When the door is

in the open position, the error codes will be shown on the left display. To advance through the error codes,

press the drop button.

- NOTE: If at the beginning of the self test mode, the claw does not drop, one or more of the following may

apply. The prize sensor is not working or is blocked. The string or string lever is mechanically binding. The up

or down switch is sticking or misaligned from its actuator.

- NOTE: If claw stays closed, it is likely that the diode has blown and the transistor controlling the claw has

also blown. Shut off the game immediately and have a qualified technician install a new coil assembly and

transistor on main board.

- NOTE: If claw is jerky while being lowered, it is likely that the up spring is missing or has not been slightly

elongated properly. Another possibility is that the string has mechanically bound on the spool. To fix the string

binding, enter the programming mode and go to mode 24. By moving the joystick to the left and right, you are

able to raise and lower the claw mechanism. Move the crane over the prize chute and lower the claw mecha-

nism all the way until it starts to wind up backwards. Reverse the motor direction to raise the claw mechanism

and properly rewind the string on the spool. Exit the programming mode and the string should be free of me-

chanical binding.

- NOTE: If the claw stays open, first check for bad fuses on the main board. Next check that there are no

wires dislodged from the connectors in the harness between the wagon and crane, the harness between the

wagon and the main board, the crane assembly and the wagon assembly. If the problem still exists, and no

fuses are blown or wires dislodged, it is likely that the transistor controlling voltage to the claw has blown on

the main board. Have the coil assembly and transistor on the main board replaced by a qualified technician.

- NOTE: If the crane / wagon, in the home position, tries to move left or back, check to see that the actuators

are both present. Next, check to see that the sensors are present. Next, check to see that the sensors and

actuators are aligned. Then check to see that the sensor wires are not dislodged from the connectors. Finally,

replace the sensor, it is likely to be bad.

16

GAME REPAIR

WARNING: ALWAYS REMOVE POWER FROM

THE GAME BEFORE ATTEMPTING ANY SER-

VICE, UNLESS NEEDED FOR SPECIFIC TEST-

ING. FAILURE TO OBSERVE THIS PRECAU-

TION COULD RESULT IN SERIOUS INJURY TO

YOURSELF AND / OR OTHERS.

TROUBLESHOOTING

PHILOSOPHY

To find problems with the game, always check the

obvious first. See that the game is plugged in and

that all of the fuses are good.

Next, check to see that all of the connectors are

firmly seated and that no wires have been pulled

out.

When trying to find out if specific components are

bad or not, try swapping them with components from

another PINNACLE CRANE™ game, if available, to

see if the problem moves with the component or

stays where it was. This will help you decide if you

have a problem with a specific component or maybe

a problem with either the wiring or the main p.c.

board. Use extreme caution when using probes or

volt meters if the game is powered up. If checking

continuity, it is important to disconnect the

harnessing at both ends, as attached they may yield

erroneous results.

If a p.c. board is suspected as causing your

problems, check to see that all of the I.C. chips are

firmly seated on the board.

MAIN P.C. BOARD

REPLACEMENT

1. Remove all A.C. power from the game

2. Unlock and open the front door

3. Carefully remove all of the connectors from the

main p.c. board.

4. Remove the 4 long plastic hexagon nuts that

secure the board to the main board housing.

5. Gently pull the p.c. board from the mounting

studs.

6. Reassemble in the reverse order using a new

main p.c. board.

FRONT GLASS

REPLACEMENT

1. Remove all A.C. power from the game.

2. Remove the (3) 10-24 carriage bolts holding the

top glass frame in place.

3. Loosen the (5) 1/4-20 kep nuts holding each side

glass retainer in place and slide retainers back.

4. Loosen and remove the (3) self tapping screws

holding the bottom glass retainer / window val-

ance in place.

5. If the glass is broken, be sure to remove all

pieces from where the new glass will rest.

6. With proper ceiling height, slide the new glass in

from the top. NOTE: Be careful to proper align

the glass with the side channels to prevent

breakage.

7. When glass is properly seated, slide the side

glass retainers into place and tighten the (5) 1/4-

20 kep nuts for each side.

8. Re-install the bottom glass retainer and tighten

into place via the (3) self tapping screws

9. Re-install the top window frame and tighten into

place via the (3) 10-24 carriage bolts.

SIDE GLASS

REPLACEMENT

1. Remove all A.C. power from the game.

2. Remove wagon and crane assemblies.

3. Remove front and rear cabinet rails and hard-

ware.

4. Remove fluorescent lights and brackets on side

where glass is to be replaced.

5. Remove (2) side window retainers and (1) top

window retainer.

6. Remove side marquee.

7. Back out long 1/4-20 bolts that hold on the side

window retainers so they are flush with the 1”

tube frame.

17

GAME REPAIR

8. Remove bolts holding playfield in place near

bottom of the glass.

9. Install new glass from the inside of the game and

drop into channel in the playfield.

10. Reinstall retainers, lights, brackets, marquee,

playfield bolts and rails in reverse order.

PLUSH RETAINER WALL

REPLACEMENT

1. Remove all A.C. power from the game.

2. Unlock and open front door

3. Carefully remove the (2) 1/4-20 nuts holding the

plastic plush retainer / wall to the side of the

game.

4. Remove old plastic plush retainer wall

5. Reassemble in reverse order using new plastic

plush retainer wall.

REMOVAL OF CRANE

MECHANISM

1. Remove all A.C. power from the game.

2. Unlock and open the front door.

3. Slide the crane assembly to the front center of

the game.

4. Loosen black thumb screw securing the front to

back micro track bracket in place. The thumb

screw is located on the front face of the crane

assembly nearest the door.

5. Slide the micro track bracket forward and up to

disconnect it from the crane assembly.

6. Carefully lift the entire crane assembly off the

rails approximately 2 inches, shift to the left as

far as possible, drop the right side down past the

right crane rail and slide the entire assembly out

from between the two separator rails.

7. The crane assembly can now be removed from

the cabinet so necessary maintenance / repairs

can be made

8. Reassemble in reverse order.

REMOVAL OF WAGON

ASSEMBLY

1. Remove all A.C. power from the game.

2. Unlock and open front door.

3. Remove crane assembly as detailed previously.

4. Loosen black thumb screw securing the micro

track bracket in place. The thumb screw is lo-

cated on the upper right face of the wagon as-

sembly at rear.

5. Slide the micro track bracket to the right and up

to disconnect it from the wagon assembly.

6. Carefully lift the entire wagon assembly off the

rails and rotate clockwise until the left front wheel

clears the front rail.

7. Lower the front of the wagon assembly and re-

move the assembly from between the two rails.

8. The wagon assembly can now be removed from

the cabinet so necessary maintenance / repairs

can be made.

9. Reassemble in reverse order.

PRIZE SENSOR

REPLACEMENT

1. Remove all A.C. power from the game.

2. Unlock and open the front door.

3. Disconnect the connector to the prize sensor

board.

4. Remove the 2 bolts holding the prize sensor

bracket to the playfield and remove the prize

sensor and bracket from the game.

5. Remove the 2 plastic hexagonal nuts securing

the sensor board to the bracket.

6. Carefully remove the sensor board from its

mounting studs.

7. Reassemble in reverse order using a new prize

sensor board.

18

GAME REPAIR

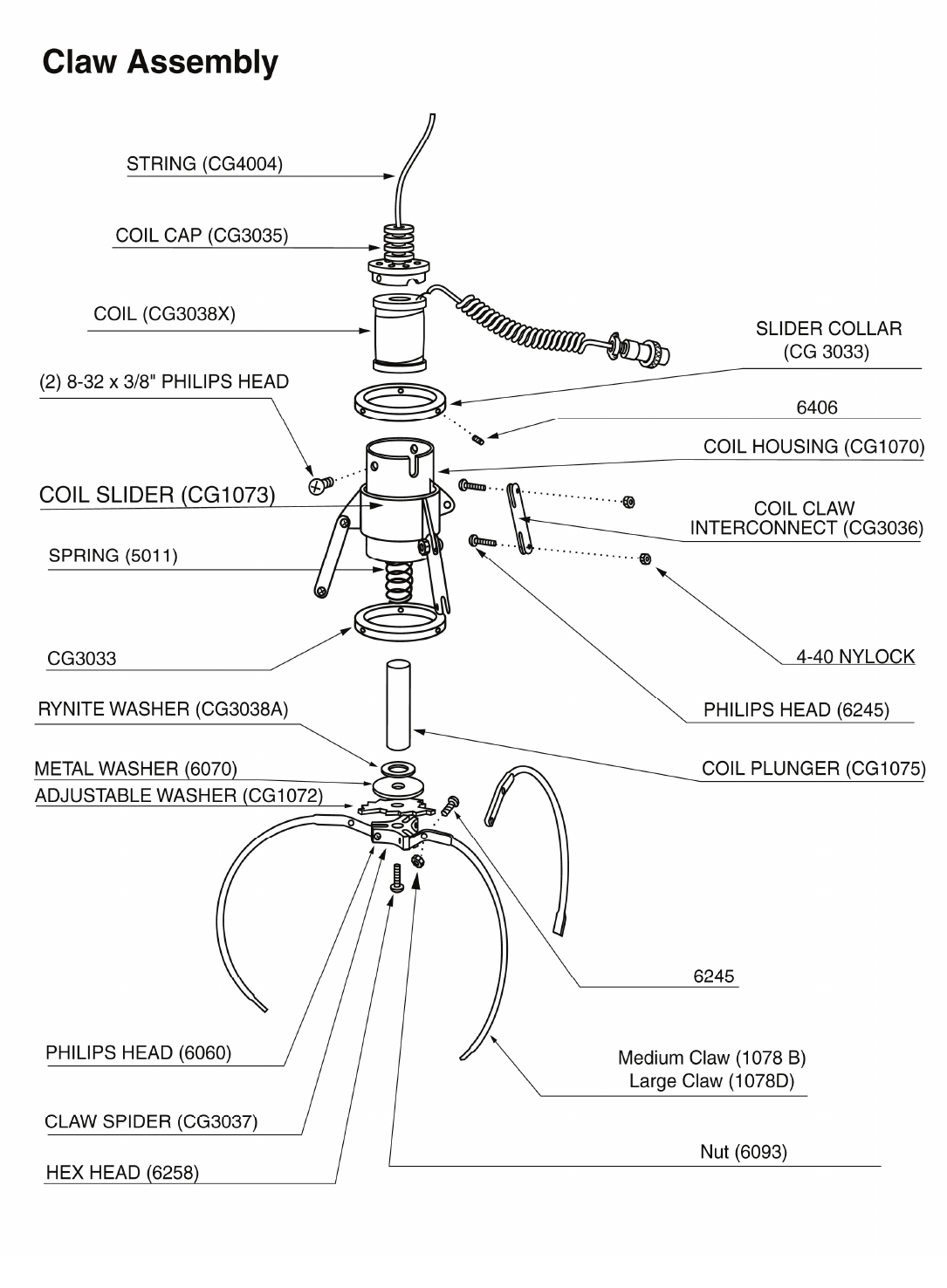

STRING REPLACEMENT

1. Remove all A.C. power from the game.

2. Unlock and open front door.

3. Remove crane assembly as previously stated.

4. Disconnect the claw assembly from the crane as-

sembly by removing the two bolts securing the alu-

minum coil cap to the coil housing.

5. Tie a knot at the end of the replacement string. Use

super glue to prevent the knot from working loose

or use a lighter to melt the knot to prevent loosen-

ing.

6. Using a lighter, melt the other end of the string and

form a point before it completely cools.

7. Remove crane housing cap by loosening the (2)

thumbscrews.

8. Feed the pointed end up through the hole in the

coil cap and pull until the knot is firmly seated on

the inside of the cap. SEE CRANE ASSEMBLY

DRAWING

9. A proper string routing diagram is located on the

bottom side of the crane housing cap.

10. Feed the pointed end up through the hole in the

bottom of the crane assembly housing.

11. Feed string over first string guide then under the

next string guide.

12. Finally, feed the string through the hole in the side

of the string spool, attached to the motor shaft, and

tie another knot. (Once again, either use super

glue to prevent the knot from working loose or use

a lighter to melt the knot to prevent loosening)

13. The string is now properly strung.

14. Re-attach the claw assembly to the crane assem-

bly using the two bolts that were removed in step 4.

15. Re-install the crane assembly into the game and

set it in the home position with the claw assembly

hanging

in the prize chute.

16. Turn on the game and the crane will automati-

cally rewind the string properly.

MOTOR REPLACEMENT

1. Remove all A.C. power from the game.

2. Unlock and open front door.

3. Remove crane and / or wagon assembly as previ-

ously stated. NOTE: What is removed depends on

which motor has gone bad.

4. Loosen two thumb screws securing crane housing

cap in place and remove. NOTE: This step is only

for the 2 motors in the crane assembly.

5. Remove drive o-rings and wheels from the bad mo-

tor.

6. Unsolder the motor leads from the bad motor.

NOTE: Be sure to note which wire goes to which

motor lead, for if they are re-installed backwards,

the motor will run opposite of its intended direction.

7. Carefully remove the bronze bushing supporting

the motor shaft of the bad motor. NOTE: This step

is only for the 2 motors in the crane assembly.

8. Remove the 4 bolts securing the motor to the hous-

ing.

9. Carefully remove the bad motor.

10. Re-assemble in reverse order using new motor.

NOTE: When motor is completely re-installed,

place one drop of thread lock on each of the 4 bolts

that secure the motor in place to prevent the bolts

from backing out.

PRECAUTION

When installing a new motor in any of the three loca-

tions, please note that the 4 screws, if tightened too

much, could mis-align the motor and cause binding. It

is advisable that you tighten the 4 screws just enough

to keep the motor from moving. Then apply a small

drop of (Blue) Loctite on the back side of each of the 4

screws to prevent the screws from loosening. When

the motor is installed properly, it should draw .5 amps

or less when running at proper 22 volts.

19

GAME REPAIR

FUSE REPLACEMENT

CAUTION FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE. REPLACE ONLY WITH

THE SAME TYPE OF FUSE HAVING THE SAME

ELECTRICAL RATING.

AREA

LOCATION AMP VOLT

MAIN BOARD F2 6 MDQ 250

F3 3 MDQ 250

F4 4 MDQ 250

POWER MOD — 3 MDQ 250

ROPE LIGHT — 3 MDQ 250

CONTROLLER

CORD REPLACEMENT

IF THE SUPPLY CORD IS DAMAGED, IT MUST BE

REPLACED BY THE MANUFACTURER OR ITS

SERVICE AGENT OR A SIMILARLY QUALIFIED

PERSON IN ORDER TO AVOID A HAZARD.

20

PARTS LISTINGS

CABINET PARTS

P802 BLACK

P100 RED

P300 YELLOW

P402 GREEN FLUORESCENT

P500 BLUE

*ADD COLOR AT END OF PART

BC1002* CORNER (REAR LEFT)

BC1003* CORNER (REAR RIGHT)

BC1005* DOOR PANEL

BC1006* DOOR FRAME

BC1007* PRIZE DOOR

BC1008* SIDE PANEL

BC1017* WINDOW FRAME TOP

BC1018* PODIUM

BC1018X PODIUM ASY

BC1023* DOOR SEAL

MECHANICAL PARTS

2027X ASY FAN

2133CW LIGHT (ROPE) WHITE CHASING

5006 CASH BOX OVER/UNDER

5011 SOLENOID SPRING

8312 BULB PL-L 40W

BC1011 BRACKET (WINDOW SIDE)

BC1013X ASY (LOCK RODS AND CAM)

BC1020 BRACKET (WAGON STOP)

BC1405 BRACKET (SHELF LEFT SIDE)

BC1406 BRACKET (SHELF RIGHT SIDE)

BC2032X PCBA (DISPLAY)

BC2052AX HARNESS (MAIN/WAGON UPPER)

BC2052X HARNESS (MAIN/WAGON LOWER)

BC2059X HARNESS (REMOTE)

BC2060X HARNESS (OPTO)

BC3003 CORNER COVER (SMOKED)

BC3008 CORNER COVER (2-WAY MIRROR)

BC3009 CORNER COVER (1 WAY MIRROR)

BC3026 MIRROR (38-1/8 x 45-1/8)

BC3027 GLASS (FRONT) 38 x 46-5/16

BC3028 GLASS (SIDE) 28 5/8 x 49

CG1055X ASY (WAGON)

CG1061X ASY (CRANE)

CG1066 SPRING (CRANE UP)

CG2002X ASY (TRANSFORMER)

CG2039X PCBA (SENSOR)

CG3005 PRIZE CHUTE

CG5014 T HANDLE (LOCK)

CG5015 LOCK (BARREL)

CP8284X ASY (BALLAST)

FP2007 SPEAKER (4" ROUND)

PP250X ASY (SOCKET)

OPTIONAL PARTS

CG1078A CLAW (SMALL)

CG1078AX ASY CLAW SMALL W/SOLENOID

CG1078B CLAW (MEDIUM)

CG1078BX ASY CLAW MEDUIUM W/ SOLE-

NOID

CG1078D CLAW (LARGE)

CG1078DX ASY CLAW LARGE W/SOLENOID

CG1078H CLAW (JEWELRY)

CG1078HX ASY CLAW JEWELRY W/ SOLE-

NOID

CG1079AX ASY CLAW (SMALL) W/O SOLE-

NOID

CG1079BX ASY CLAW (MEDIUM) W/O SOLE-

NOID

CG1079DX ASY CLAW (LARGE) W/O SOLE-

NOID

CG1079HX ASY CLAW JEWELRY W/O SOLE-

NOID

GRAPHICS & DECALS

BC7012 CONTROL PANEL

BC7026 MARQUEE SIDE

BC7027 MARQUEE FRONT

JEWELRY BOX OPTION

BC7412 CONTROL PANEL

BC7426 LEFT SIDE DECAL

BC7427 MARQUEE FRONT

BC7428 RIGHT SIDE DECAL

21

22

23

24

25

26

27

28

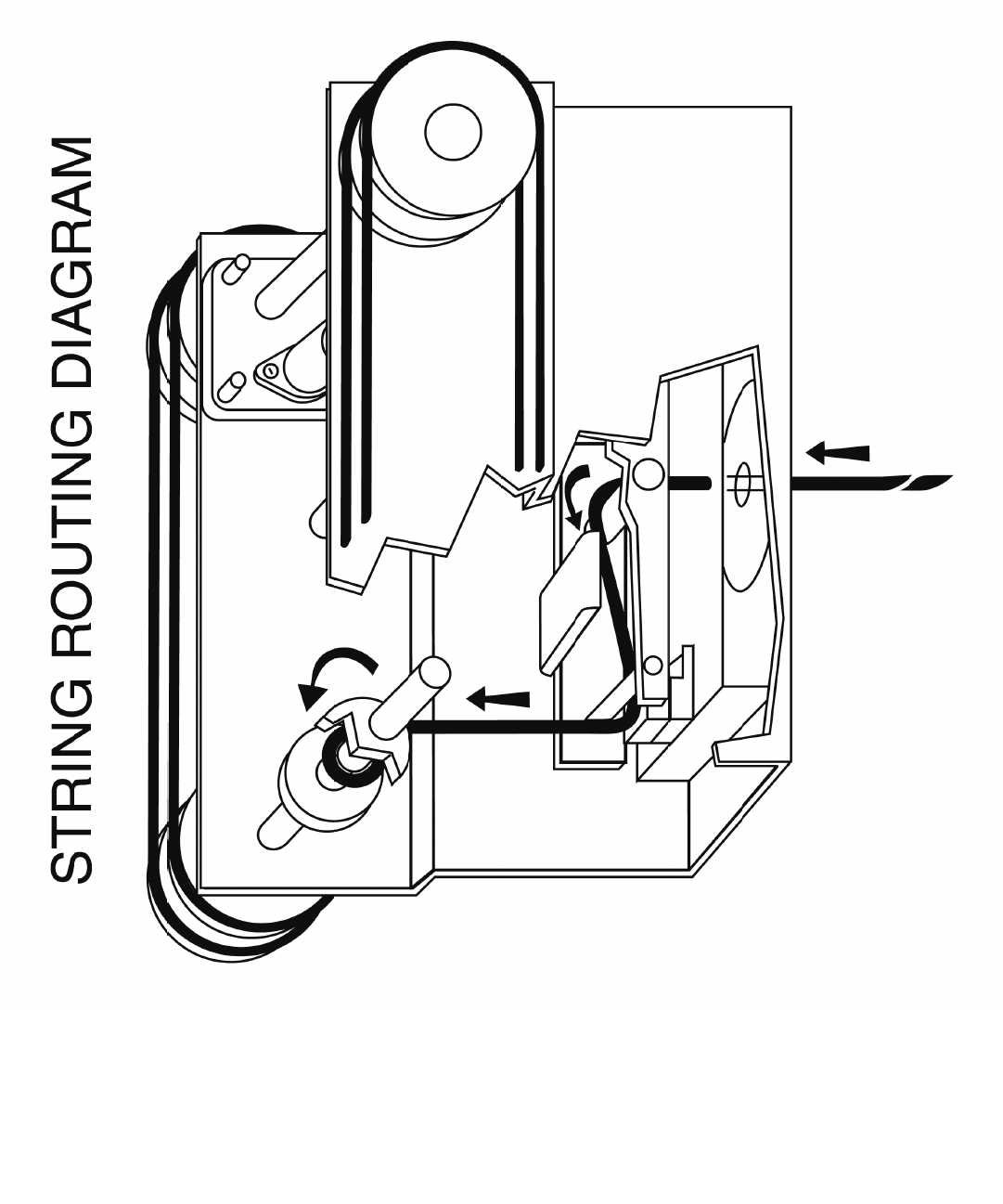

SPEAKER

COIN

LAMPS

CG2002X 110V

XFMR

DOOR INTERLOCK

ACCOUNTING

PROGRA

M

FORWARD

RIGHT

BACK

LEFT

DROP

VOLUM

E

CG1061X

CRANE

CG1055X

WAGON

CG1078DX

CLAW

P1

CLEAR

LAMP

CLEAR

LAMP

REDRED

COIN

COUNTER

PRIZE

COUNTER

P7

P4

P10

P3

P8

P2

P6

P9

BRIGHT

STICK

LAMPS

2027X

FAN

CG2039X

PRIZE

SENSOR PCB

CG2032X

DISPLAY PCB

MARS

AE2400

DBV

CG2006X

WORKBOX

COIN 1

COIN 1

CG2052X

MAIN TO

WAGON

CG2053X

WAGON TO

CRANE

CG2062X

FAN

HARNESS

CG2006X

FLASHING

LIGHTS

CG2063X

COUNTER

ASY.

CG2060X

OPTO

HARNESS

CG2061X

OPTO EXT.

HARNESS

CG2057X

INTERNAL

LIGHTS

HARNESS

CG2066X

DBV EXT.

HARNESS

CG2058X

LAMPS/

SWITCH

HARNESS

CG2058X

CG2059X

REMOTE

HARNESS

CG2054X

DISPLAY

HARNESS

CG2050X

DOOR

HARNESS

CG2034X

MAIN PCB

DATE

2/19/98

DESCRIPTION

CRANE WIRING DIAGRAM

DRAWN BY

RMO

FILENAM

E

PLUSH3.VSD

PAGE

1 OF 17

REVISED

11/15/00

29

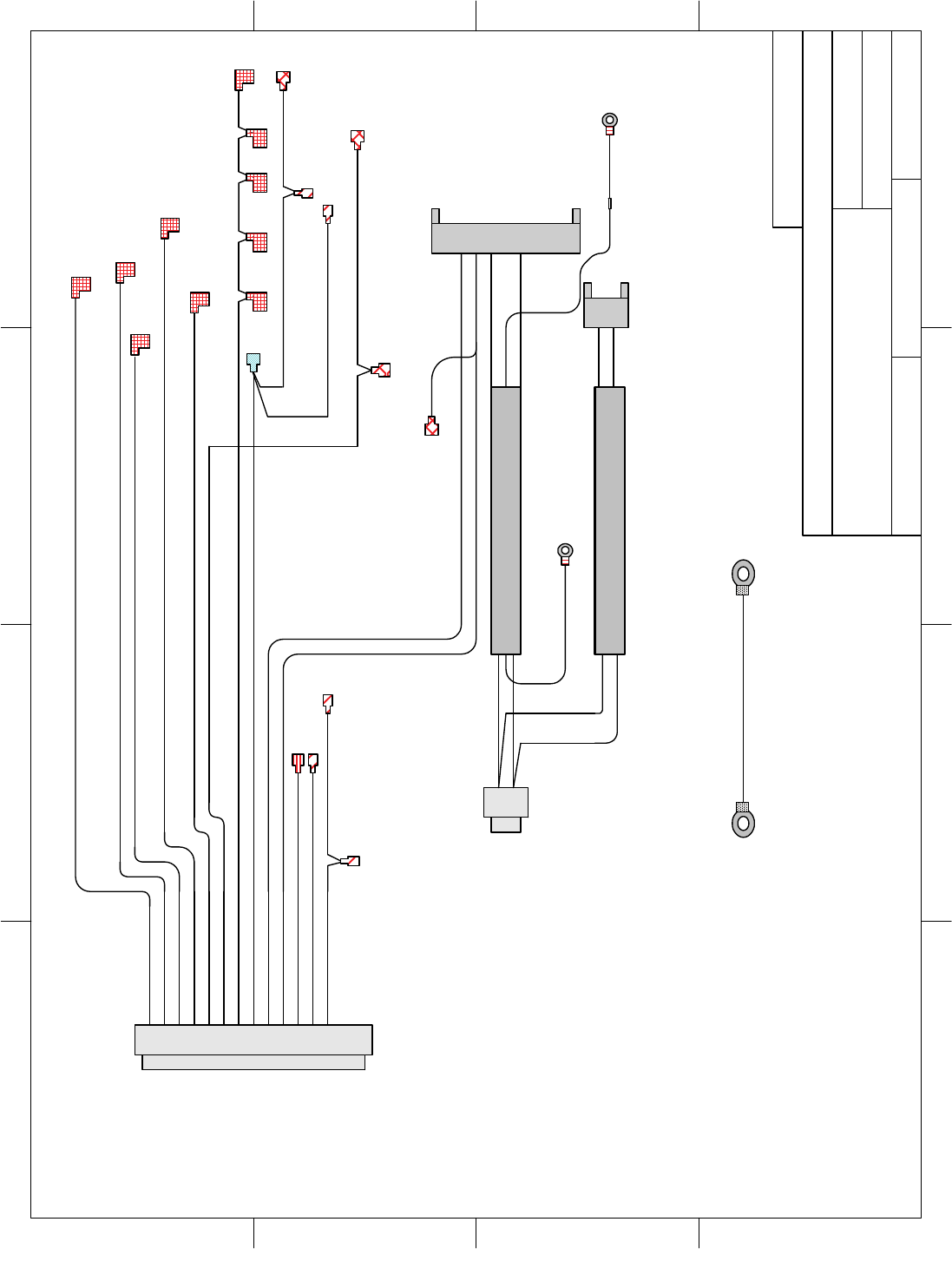

123

456

987

101112

15 14 13

123

456

987

101112

123

456

987

123

456

123

123

1234

1. MOTOR UP

2. MOTOR DOWN

3. HOME LEFT / RIGHT SENSOR

4. CLAW UP SENSOR

5. CLAW DOWN SENSOR

6. CLAW CLOSE ( CLAW - )

7. GROUND

8. GROUND

9. MOTOR RIGHT

10. MOTOR BACK

11. HOME FRONT / BACK SENSOR

12. MOTOR LEFT

13. MOTOR FORWARD

14. CLAW POWER ( CLAW + )

15. 36V

1. GROUND

2. PROGRAM BUTTON

3. ACCOUNTING

4. GROUND

5. AUDIO TOP

6. AUDIO WIPER

123

456

987

101112

15 14 13

1. JOYSTICK UP

2. JOYSTICK DOWN

3. JOYSTICK RIGHT

4. JOYSTICK LEFT

5. JOYSTICK BUTTON

6. COIN INPUT

7. GROUND

8. GROUND

9. GROUND

10. DOLLAR BILL VALIDATOR

11. SPEAKER +

12. SPEAKER -

13. 12 VOLTS

14. KEY

15. GROUND

1. SEGMENT A

2. SEGMENT B

3. SEGMENT C

4. SEGMENT D

5. SEGMENT E

6. SEGMENT F

7. 12 VOLTS

8. SEGMENT H

9. SEGMENT G

10. SELECT 1

11. SELECT 2

12. GROUND

1. 12 VOLTS

2. PRIZE SENSOR

3. GROUND

1. PRIZE COUNTER

2. 5 VOLTS

3. MCOIN / CREDIT COUNTER

123

456

987

1. TICKET SENSE

2. GROUND

3. TICKET RUN

4. 12 VOLTS

1. 12 VOLTS

2. 12 VOLTS

3. 12 VOLTS

4. DOOR SWITCH

5. 12 VOLTS

6. HEADLIGHTS

7. LEFT BLINKER

8. RIGHT BLINKER

9. GROUND

1. KEY

2. 16 VAC

3. 10 VAC

4. 36 VAC

5. 10 VAC

6. 13 VAC

7. 36 VAC

8. 16 VAC

9. 13 VAC

P1

CARRAGE

P4

PRIZE

SENSOR

P8

COUNTERS

P2

REMOTE

P6

DISPLAY

P9

DOOR

P3

TICKETS

P7

LIGHTS

P10

POWER

DATE

2/19/98

DESCRIPTION

DRAWN BY

RMO

FILENAM

E

PLUSH3.VSD

PAGE

2 OF 17

REVISED

11/15/00

TITLE

CRANE MAIN BOARD

CONNECTOR PIN OUT

30

D

C

B

A

4321

D

C

B

A

4321

DATE

3/22/99

DESCRIPTION

REMOTE ASSEMBLY

DRAWN BY

CMZCMZ

FILENAME

BASIC.VSD

PAGE

1 OF 6

REVISED

7/3/01

TITLE

BASIC CRANE#BC3003X

Ground

Program

Acct.

Ground

Audio

Audio Pot

1

2

3

4

5

6

6 PIN PLUG #2173

SOLID PIN #2100S

black

black/blue

white/gray

black

red/white

red/black

"

21

"

20

"

19

"

22

"

22

"

22

#BC2059X-REMOTE

HARNESS

"

2

#BC3003X-REMOTE

ASSEMBLY

PROGRAM

ACCT.

ACCT.

LC BRACKET

white/gray black/blue

GND POT AUD

P2

REMOTE

31

D

C

B

A

4321

D

C

B

A

4321

QTY

1

PER GAME

DATE

3/22/99

DESCRIPTION

#BC2050X

DOOR

DRAWN BY

CMZ

FILENAME

BASIC.VSD

PAGE

2 OF 6

REVISED

7/3/01

TITLE

BASIC CRANE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15 PIN PLUG #2144

SPLIT PIN #2100

9

8

7

6

5

4

3

2

1

1

2

2 PIN PLUG #2103

14awg PIN #2422

white/black

white/brown

white/orange

white/red

white/yellow

black/brown

black

black

black/white

yellow

red/gray

brown/gray

orange

P9

DOOR

22"

4" 4" 4"

21" 14"

14"

BLACK

WHITE

9-PIN CAP MINI #2568

MALE PIN MINI #2569

Joy Up

Joy Down

Joy Right

Joy Left

Button

Coin 1

Ground

Ground

Ground

DBV

Speaker +

Speaker -

+12v

KEY(not used)

Ground

TO

MAIN

PCB

TO

JOYSTICK

UP

LEFT

BUTTON

RIGHT

DOWN

COIN1

COIN1

JOYSTICK

GROUND

LAMP

AND COIN

GROUND

COIN LAMP

POWER

TO MARS

2400AE

DBV

TO DBV POWER

EXTENTION HARNESS

#653T

#653T

#639

#650

#650

#650

#650

WHITE

BLACK

#2874- 3 CONDUCTOR CABLE

#2874- 3 CONDUCTOR CABLE

GREEN

#PC20217

"

46.5

"

60

#2513

BLACK

WHITE

#PC20217

2"

STRIP

"

15

GREEN/YELLOW

GREEN

yellow

black/white

"

98

"

100

"

97

"

108

"

97

"

92

"

98

"

92

"

98

"

98

"

88

"

88

"

98

"

38

5"

#650

#651

4" STRIP

4" STRIP

.250 FLAG

#648

.250 FLAG

#648

.250 FLAG

#648

.250 FLAG

#648

.250 FLAG

#648

.250 FLAG

#648

#652#652

#BC2004X-12" GROUND

WORKBOX

DOOR

#653T

FOR BC IT GOES BETWEEN TRANSFORMER & WORKBOX#1

CAGE & WORKBOX#2

FOR CP IT GOES BETWEEN TRANSFORMER & WORKBOX

NO CAGE

2 PIN CAP #2181

FEMALE PIN #2102

1

2

#2955-SPIRAL WRAP

43" SEE SAMPLE

AND BOARD.

#653T

32

use #8162-14 awg male mini

32

D

C

B

A

4321

D

C

B

A

4321

DATE

3/22/99

DESCRIPTION

#BC2054X

Display

DRAWN BY

CMZRMO

FILENAME

BASIC.VSD

PAGE

3 OF 6

REVISED

7/3/01

TITLE

BASIC CRANE

1

2

3

4

5

6

7

8

9

10

11

12

12 PIN PLUG #2106

SPLIT PIN #2100

1

2

3

4

5

6

7

8

9

10

11

12

12 PIN PLUG #2106

SPLIT PIN #2100

brown

red/black

orange/black

yellow

green

blue

ORANGE

gray

white

black/white

tan

BLACK

Seg a

Seg b

Seg c

Seg d

Seg e

Seg f

+12v

Seg h

Seg g

Sel 1

Sel 2

ground

P6

DISPLAY

"

95

TO MAIN PCB

TO DISPLAY

PCB

QTY

1

PER GAME

33

D

C

B

A

4321

D

C

B

A

4321

DATE

3/22/99

DESCRIPTION

#BC2058X

DOOR INTERLOCK

DRAWN BY

CMZRMO

FILENAME

BASIC.VSD

PAGE

5 OF 6

REVISED

7/3/01

TITLE

BASIC CRANE

PER GAME1QTY

1

2

3

4

5

6

7

8

9

9 PIN PLUG #2292

SOLID PIN #2100S

yellow/black

black

"

40

"

40

#651

#651

P7

34

D

C

B

A

4321

D

C

B

A

4321

QTY

1

PER GAME

DATE

3/22/99

DESCRIPTION

#BC2060X

Opto

DRAWN BY

CMZRMO

FILENAME

BASIC.VSD

PAGE

6 OF 6

REVISED

7/3/01

TITLE

BASIC CRANE

1

2

3

3 PIN PLUG #2206

SOLID PIN #2100S

1

2

3

3 PIN HOUSING #2945

CONTACT PIN #2201

12"

orange

green/black

black

+12

Prize

Ground

TO MAIN PCB

TO OPTO PCB

P4

35

D

C

B

A

4321

D

C

B

A

4321

DATE

2/19/98

DESCRIPTION

Main/Wagon

UPPER & LOWER

DRAWN BY

CHERYLZ1RMO

FILENAM

E

PLUSH3.VSD

PAGE

3 OF 17

REVISED

11/15/00

TITLE

QTY

1

PER GAME

1

2

6

9

10

12

13

14

3

4

5

7

8

11

15

15 PIN PLUG #2144

SPLIT PIN #2100

BROWN

RED

BROWN

ORANGE

YELLOW

GREEN

BLUE

BLUE

red

brown

green

black

blue

white

Motor Up

Motor Down

Claw -

Motor Right

Motor Bk

Motor Lt

Motor Fd

Claw +

Home L/R

Claw Up

Claw Down

Ground

Ground

Home F/B

36v

Motor Up

Motor Down

Claw -

Motor Right

Motor Bk

Motor Lt

Motor Fd

Claw +

Home L/R

Claw Up

Claw Down

Ground

Ground

Home F/B

EARTH

1

2

6

9

10

12

13

14

3

4

5

7

8

11

15

15 PIN PLUG #2144

MALE PIN #2100

BROWN

RED

BROWN

ORANGE

YELLOW

GREEN

BLUE

BLUE

red

brown

green

black

blue

white

GREEN/YELLOW

(91" CG)

GREEN/YELLOW

#2997-2 CONDUCTOR

POWER CORD

TO MAIN PCB

P1

CARRAGE

TO WAGON

HARNESS

TO FRAME

#652

3" STRIP

Motor Up

Motor Down

Home L/R

Claw Up

Claw Down

Claw -

Ground

Ground

Motor Right

Motor Bk

Home F/B

Motor Lt

Motor Fd

Claw +

EARTH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15 PIN PLUG #2144

MALE PIN #2100

TO WAGON

EXTENSION

TO WAGON TO

CRANE

HARNESS

NOTE:

PRIOR TO 9/11/98

THIS CONNECTOR

WAS A 15 PIN MINI

PLUG W/ FEMALE

PINS

**BEND THIS END

#1 PIN IS DOWN

15 PIN CAP #2367

FEMALE PIN #2102

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

NOTE:

PRIOR TO1/7/99

THIS HARNESS WAS

PART OF THE WAGON

EXTENSION HARNESS

QTY

1

PER GAME

MAIN TO WAGON LOWER HARNESS

MAIN TO WAGON UPPER HARNESS

"

(50 LC & MC)

#CG2052X #LC2052X

"

60" CG

"

81" LC

#CG2052AX #LC2052AX

TWISTED WIRE

TWISTED WIRE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

GREEN/YELLOW

#BC2052X

"

(138" BC)

"

48" BC

#BC2052AX

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

GREEN/YELLOW

"

21

CUT 62" CUT 50" CUT 86" CUT 110"

#WC2052AX

CUT 100"

"

97" MC

#MC2052AX

#WC2052X

"

(60" WC)

"

(130" CP)

#CP2052X

"

108" WC

CUT 42"

"

39.5" CP

#CP2052AX

Motor Up

Motor Down

Home L/R

Claw Up

Claw Down

Claw -

Ground

Ground

Motor Right

Motor Bk

Home F/B

Motor Lt

Motor Fd

Claw +

EARTH

36

D

C

B

A

4321

D

C

B

A

4321

QTY

1

PER GAME

DATE

2/19/98

DESCRIPTION

Wagon /Crane

DRAWN BY

CHERYLZ1RMO

FILENAM

E

PLUSH3.VSD

PAGE

4 OF 17

REVISED

11/15/00

TITLE

#CG2053X

1

2

3

4

5

6

7

8

9

10

11

12

12 PIN PLUG #2106

Male Pin #2100

34.5" (CUT 36")

CG2053X

BC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

R/L

Motor

Home

sensor F/B

Sensor

L/R

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

GREEN/YELLOW

"

8

"

8

"

31.5

#2835- SHIELD

Motor Up

Motor Down

Home L/R

Claw Up

Claw Down

Claw -

Ground

Ground

Motor Right

Motor Bk

HomeF/B

Motor Lt.

Motor Fd.

Claw +

Shield

Motor Up

Motor Down

Motor Fd.

Claw Up

Claw Down

Claw -

Ground

Claw +

Motor Bk

Shield

GREEN

ORANGE

TO MAIN TO

WAGON

HARNESS

TO CRANE

HARNESS

+

NOTE:SHIELD

REQUIRED FOR CE

GAMES ONLY

USE A #2422-14 AWG

MALE PIN WHEN

USING SHIELD

IN PIN 12.

NOTE:

PRIOR TO 9/11/98

THIS CONNECTOR WAS A 15 PIN MINI CAP

W/ MALE PINS #8162-20-16 AWG MINI

NOTE:

PRIOR TO 9/11/98

THIS CONNECTOR WAS A 12 PIN MINI

PLUG WITH FEMALE PINS #8163-MINI

GREEN/YELLOW

30" (CUT AT 32")

LC2053X

"

5

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

GREEN/YELLOW

#652

"

7

GREEN/YELLOW

15 PIN CAP #2367

FEMALE PIN #2102

PIN #15 USE #2013-14 AWG

FOR 60" SL SINGLE DO THE HIGHLIGHTED AREAS!!!

MOVE OVER ON CRANE ASY

"

28

37

D

C

B

A

4321

D

C

B

A

4321

DATE

2/19/98

DESCRIPTION

Crane

DRAWN BY

CHERYLZ1RMO

FILENAM

E

PLUSH3.VSD

PAGE

5 OF 17

REVISED

11/15/00

TITLE

#CG2056X

QTY

1

PER GAME

12 PIN CAP #2105

FEMALE PIN #2102

1

2

3

4

5

6

7

8

9

10

11

12

F/B

Motor

Sense

Up

Sense

Down

"

8

U/D

Motor

1

2

3

4

Retractable Cord

Claw

Solenoid

BLACK

WHITE

WHITE

BLACK

4-PIN CIRCULAR

CONN.

Motor Up

Motor Down

Motor Fd

Claw Up

Claw Down

Claw -

Ground

Claw +

Motor Bk

Shield

BROWN

RED

BLUE

BLACK

WHITE

YELLOW

GREEN/YELLOW

"

8

"

8

"

5

"

6

"

8

"

8

"

8

"

6

"

8

"

5

TO WAGON TO

CRANE

HARNESS

+

+

NOTE:

PRIOR TO 9/11/98

THIS CONNECTOR

WAS A 12 PIN MINI

CAP WITH MALE PINS

#653

CONN IS PART OF THE CRANE BOM

SUB ASY SOLDERS THE WIRES FOR

THE MOTORS DIRECT AND ADDS THE

PINS ON THE SENSORS MAKING THOSE

PARTS PART OF THE CRANE BOM!

38

D

C

B

A

4321

D

C

B

A

4321

DATE

2/19/98

DESCRIPTION

Counter

DRAWN BY

CHERYLZ1RMO

FILENAM

E

PLUSH3.VSD

PAGE

12 OF 17

REVISED

11/15/00

TITLE

#CG2063X

QTY

1

PER GAME

1

2

3

3 PIN PLUG #2206

SOLID PIN #2100S

Prize

Counter

5v

Coin

Counter

5v

Red

Black

Black

Red

brown/white

orange

brown

PCNTR

+5v

CCNTR

P8

Counter

"

18

TO MAIN PCB

#2558

#2558

#2558

#2558

39

D

C

B

A

4321

D

C

B

A

4321

DATE

2/19/98

DESCRIPTION

110v Transformer

DRAWN BY

CHERYLZ1RMO

FILENAM

E

PLUSH3.VSD

PAGE

14 OF 17

REVISED

11/15/00

TITLE

#CG2002X/CG2004X

120V TO

DBV

Lamps 12v unregulated

Motors 22v unregulated

Claw 36v regulated

Logic 12v regulated

TRANSFORMER #CG2002

120v PRIMARY MCI# 2-51-9813

1

3

5

2

8

4

7

6

9

9 PIN PLUG #2292

20-14 awg MALE #8260

10.5v ac @ 3.0 A ac 90%

16.5v ac @ 3.5 A ac 85%

36v ac @ 3.5 A ac 60%

13.2v ac @ 2.0 A ac 100%

BLUE

BLUE

ORANGE

ORANGE

YELLOW

YELLOW

RED

RED

KEY

"

36

1

2

2 PIN CAP #2181

FEMALE PIN #2102

1

2

BLACK

WHITE

BLACK

WHITE

120v To AC

INTERNAL

LIGHTS

PRIMARY 120v

"

8

"

8

1

2

3

BLACK

WHITE

"

12

15"

#CG2004X

**PUT 29" OF #2955-BLACK SPIRAL

WRAP 3" BACK FROM THE

CONNECTOR.

To 120v

SWITCH

BOX

SECONDARY

TRANSFORMER

COVER

FRAME

GREEN/YELLOW

#652 #652

3 PIN PLUG #2206

MALE PIN #2422

2 PIN CAP #2181

FEMALE PIN #2013

40

D

C

B

A

4321

D

C

B

A

4321

DATE

9/15/99

DESCRIPTION

#CP8284X-ASY BALLAST

#CP2081X-HARNESS AC BALLAST

DRAWN BY

RMO

FILENAM

E

CRANPUSH2.VSD

PAGE

16 OF 16

REVISED

12/4/00

TITLE

Cranpush

D

C

B

A

4321

D

C

B

A

4321

.250 YELLOW

MALE #8282

.250 YELLOW

MALE #8282

WITH

SPRING

WITH

SPRING

.250 YELLOW

MALE #8282

#8284-BALLAST

(MODEL#WH6-120-6)

1

2

3

YELLOW

RED

#PC20217

BLACK

GREEN/YELLOW

WHITE

3 PIN PLUG #2206

SOLID PIN #2100S

PIN 1+3 USE #8260-20-14 AWG MALE

"

18

#8283 - FLOURESCENT BULB (24" HO)

#8283 - FLOURESCENT BULB (24" HO)

1

2

3

3 PIN CAP #2288

FEMALE #2102

BLACK

GREEN

WHITE

#8173-3 CONDUCTOR SVT CABLE

#CP2081X- AC BALLAST HARNESS

BLACK

WHITE

TO TRANSFORMER

"

5 1/2

"

5 1/2

"

10

"

10

"

6

"

5

#DD8239SX-SOCKET

ASY W/SPRING

#DD8239SX-SOCKET

ASY W/SPRING

1

2

2 PIN PLUG #2103

SOLID PIN #2100S

#DD8239BX-SOCKET ASY

#PC20217

"

10

#CP8284X- ASY BALLAST

#CG2081X- AC BALLAST HARNESS

CP

123"

CG

88"

"

5

#639

#639

#639

"

28

#DD8239BX-SOCKET ASY

.250 #653T

41

1

2

3

4

4 PIN PLUG #2099

SOLID PIN #2100S

4 PIN MLX CAP #2158

FEMALE PIN #2176

1

2

3

4

4 PIN CAP #2101

FEMALE PIN #2102

1

2

3

4

1

2

3

4

4 PIN PLUG #2099

SOLID PIN #2100S

4 PIN MLX CAP #2158

FEMALE PIN #2176

1

2

3

4

To Fan

To Ticket Dispenser

blue

black *2

white

orange *2

black

orange

black

orange

blue

black

white

orange

D

C

B

A

4321

D

C

B

A

4321

DATE

2/16/01

DESCRIPTION

DRAWN BY

MMARTIN

FILENAME

FANTICKET.VSD

PAGE

1 OF 1

REVISED

2/27/01

TITLE

FanTicket Extension

95

"

60

"

15

"

#CG2064X-FAN HARNESS

#CG2062X-FANTICKET EXTENSION

HARNESS

42

D

C

B

A

4321

D

C

B

A

4321

DATE

7/2/98

DESCRIPTION

LITTLE CRANE

DRAWN BY

RMORMO

FILENAM

E

LC.VSD

PAGE

2 OF 4

REVISED

8/31/00

TITLE

1

2

3

4

5

6

7

8

9

10

11

12

12 PIN PLUG #2106

SPLIT PIN #2100

1

2

3

4

5

6

7

8

9

10

11

12

12 PIN PLUG #2106

SPLIT PIN #2100

brown

red/black

orange/black

yellow

green

blue

ORANGE

gray

white

black/white

tan

BLACK

Seg a

Seg b

Seg c

Seg d

Seg e

Seg f

+12v

Seg h

Seg g

Sel 1

Sel 2

ground

P6

Display

"

55

#LC2054X-DISPLAY HARNESS

D

C

B

A

4321

D

C

B

A

4321

1

2

3

4

5

6

7

8

9

9 PIN PLUG #2292

SOLID PIN #2100S

yellow/black

black

"

27

#651

#651

#LC2058X-DOOR INTERLOCK

1

2

3

3 PIN PLUG #2206

SOLID PIN #2100S

Prize

Counter

5v

Coin

Counter

5v

Red

Black

Black

Red

PCNTR

+5v

CCNTR

"

6

COUNTER

P8

#2558

brown/white

orange

brown

#LC2063X-COUNTER

#LC2055X-POWER BOX HARNESS

3 PIN CAP #2288

FEMALE #2102

1

2

3

#651

#651

#652 #638

#PC20217

"

12

"

14

GREEN/YELLOW

BROWN

BLUE

"

3

P1

P7

43

D

C

B

A

4321

D

C

B

A

4321

DATE

6/23/00

DESCRIPTION

DRAWN BY

CHERYLZ1

FILENAM

E

LIGHT ROPE

CONTROLLER.VS

D

PAGE

1 OF 1

REVISED

12/6/00

TITLE

LIGHT ROPE CONTROLLER

P1

P2

#2033X

PCBA-ROPE LIGHT

CONTROLLER

1

2

3

4

5

5 PIN HOUSING #2419

AMP CONTACT PIN #2201

TO LIGHT

ROPE

"

BROWN

BLACK

BLUE

#2090X-ROPE LIGHT HARNESS

FOR- WK,DC

1

2

3

4

5

5 PIN HOUSING #2419

AMP CONTACT PIN #2201

BROWN

BLACK

BLUE

TO LIGHT

ROPE

TO LIGHT

ROPE

TO LIGHT

ROPE

FOR-JC

#JC2090X-ROPE LIGHT HARNESS

BROWN

BLK

BLUE

"

8

BUCHANAN

INSULATOR &

SPLICE CAP

1

2

3

4

5

5 PIN HOUSING #2419

AMP CONTACT PIN #2201

BROWN

BLACK

BLUE

P2

P2

P2

#CP2090X-ROPE LIGHT HARNESS

FOR-CP&AC

3 PIN HOUSING #2945

WITH AMP CONTACT #2201

1

2

3

1

2

2 PIN PLUG #2103

SOLID PIN #2100S

BLACK

WHITE

BLACK

WHITE

"

18

#8173-SVT

P1

#2089X-AC ROPE LIGHT HARNESS

FOR JC,DC,DCSL,CP,CP AIR CONDITIONER

3 PIN HOUSING #2945

WITH AMP CONTACT #2201

1

2

3

#8173-SVT

WHITE

BLACK

P1

1

2

3

3 PIN PLUG #2206

SOLID PIN #2100S

BLACK

WHITE

"

10

#WK2089X-AC ROPE LIGHT HARNESS

FOR WK

6 1/2

#PC20217

"

18

44

I.C.E warrants all components in the PINNACLE CRANE™ game to be free of

defects in materials and workmanship for a period of ninety days from the date of

purchase.

This warranty does not cover items damaged due to normal wear and tear,

subjected to abuse, improperly assembled by the end user, modified, repaired, or

operated in a fashion other than that described in the service manual.

If your PINNACLE CRANE™ game fails to conform to the above-mentioned