Report on Determining the Reactivity of Concrete Aggregates and

Selecting Appropriate Measures for Preventing Deleterious

Expansion in New Concrete Construction

Notice

This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of

information exchange. The U.S. Government assumes no liability for the use of information contained in this

document.

This report does not constitute a standard, specication, or regulation.

Quality Assurance Statement

The Federal Highway Administration provides high-quality information to serve Government, industry, and the

public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize

the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and

adjusts its programs and processes to ensure continuous quality improvement.

FHWA-HIF-09-001

Table of Contents

1.0 Introduction................................................................................. 1

2.0 General Approach....................................................................... 1

3.0 Testing To Determine Aggregate Reactivity.............................. 3

3.1. Use of Field Performance History........................................ 3

3.2. Petrographic Assessment...................................................... 5

3.3. Determination of Potential Alkali-Carbonate Reactive

Rocks by Chemical Composition, CSA A23.2-26A............ 5

3.4. Accelerated Mortar Bar Test, ASTM C 1260....................... 6

3.5. Concrete Prism Test, ASTM C 1293 ................................... 7

3.6. Interpretation of Results from Laboratory Tests................... 7

3.7. Risk Evaluation..................................................................... 8

3.8. Other Test Methods............................................................... 8

4.0 Preventing Damaging Expansion In Concrete Containing

Alkali-Silica Reactive Aggregates............................................... 8

4.1. Performance Testing Using the Concrete Prism Test (CPT).. 9

4.2. Performance Testing Using the Accelerated Mortar Bar Test

(AMBT).................................................................................. 10

4.3. Prescriptive Approach for Selecting Preventive Measures..... 12

4.3.1. Degree of Aggregate Reactivity............................ 12

4.3.2. Level of ASR Risk................................................ 12

4.3.3. Determination of the Level of Prevention............. 13

4.3.4. Identication of Preventive Measures................... 14

5.0 Summary......................................................................................... 18

6.0 References....................................................................................... 19

1

Report A: Determining The Reactivity Of Concrete Aggregates

And Selecting Appropriate Measures For Preventing Deleterious

Expansion In New Concrete Construction

1.0 Introduction

Alkali-aggregate reactions (AAR) occur between the alkali hydroxides in the pore solution of concrete

and certain minerals found in some aggregates. Two types of AAR reaction are currently recognized

depending on the nature of the reactive mineral; alkali-silica reaction (ASR) involves various types of

reactive silica (SiO

2

) minerals and alkali-carbonate reaction (ACR) involves certain types of dolomitic

rocks (CaMg(CO3)

2

). Both types of reaction can result in expansion and cracking of concrete

elements, leading to a reduction in the service life of concrete structures.

This report describes approaches for identifying deleteriously reactive aggregates¹ and selecting appro-

priate preventive measures to minimize the risk of expansion when such aggregates are used in con-

crete. Preventive measures include avoiding the reactive aggregate, limiting the alkali content of the

concrete, using supplementary cementing materials, using lithium-based admixtures, or a

combination of these strategies.

2.0 General Approach

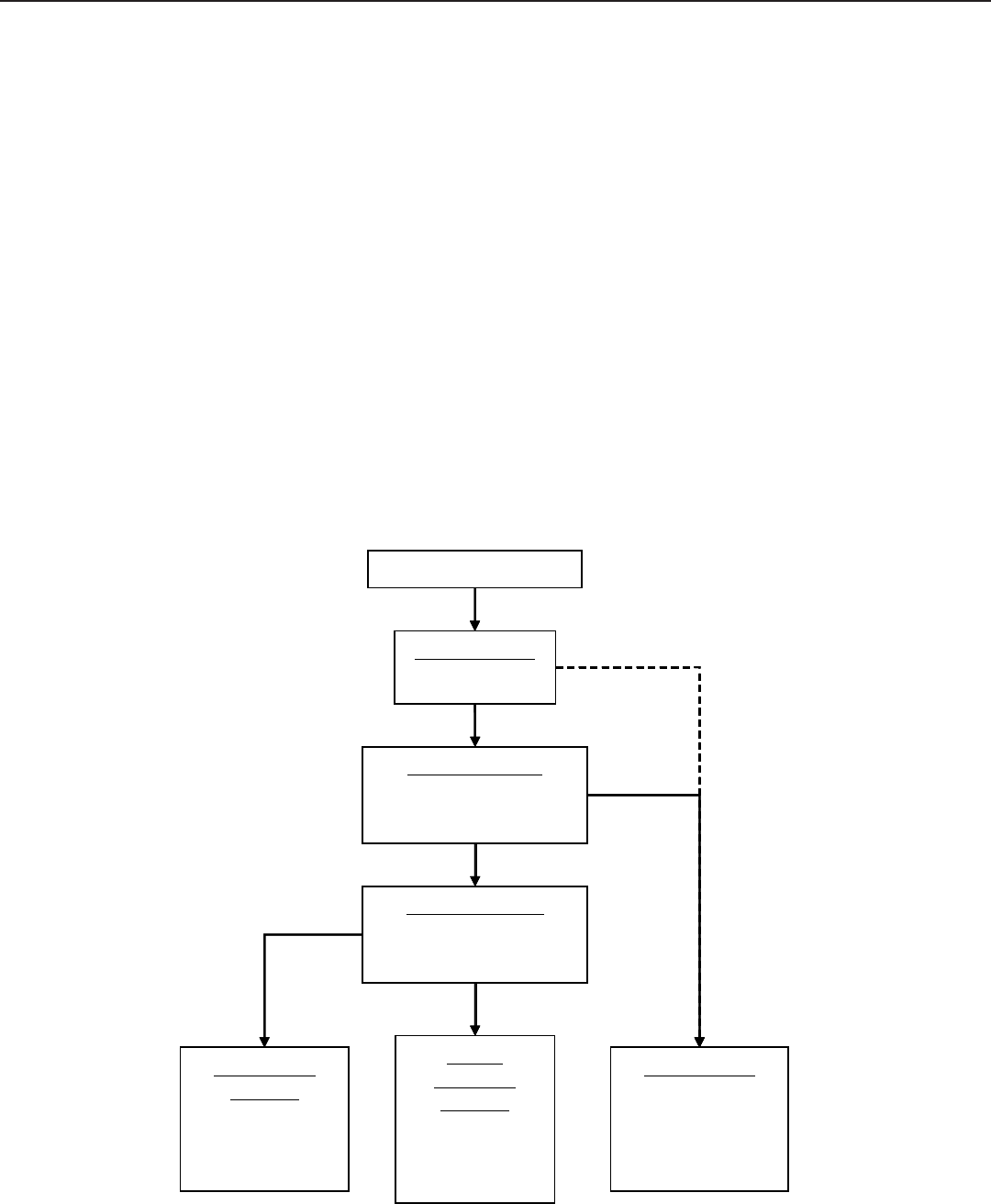

The ow chart in Figure 1 shows the general sequence of testing and decisions that have to be made

when evaluating a source of aggregate for potential AAR. Prior satisfactory eld performance of the

aggregate in concrete is considered in some cases to be sufcient for its acceptance in new concrete.

However, the use of eld performance in the absence of testing may not be sufcient to completely

safeguard against damage due to AAR in new construction because of the difculties in assuring that

the materials used in existing structures built ten to twenty years ago (time frame needed to ensure that

AAR has not occurred) are similar to those being proposed for use today. In most cases, it will be

necessary to conduct laboratory tests to determine whether or not the aggregate is deleteriously

reactive. There are many test methods available for evaluating aggregate reactivity, but only two ex

pansion tests, together with petrographic examination are recommended in this report. If the

aggregate is deemed to be non-deleteriously-reactive, it can be accepted for use in concrete with no

further consideration of mitigation (assuming that the physical properties of the aggregate render it

suitable for use). If the aggregate is found to be deleteriously reactive, it must then be determined

whether the reaction is of the alkali-carbonate or alkali-silica type. There are no proven measures for

effectively preventing damaging expansion with alkali-carbonate reactive rocks and such materials

must be avoided by selective quarrying or beneciation. If the aggregate is alkali-silica reactive, the

aggregate may be either rejected for use or accepted with an appropriate preventive measure.

¹The term deleteriously reactive is used to dene aggregates that undergo chemical reactions in

concrete which subsequently result in damage to the concrete. Some aggregates with minor amounts of reactive constituents may exhibit some small

amount of reaction without producing any damage to the concrete; these are non-deleteriously reactive aggregates.

2

There are a number of options for minimizing the risk of expansion with alkali-silica reactive rocks.

This report allows for preventive measures to be evaluated on the basis of performance testing or to be

selected prescriptively from a list of options based on previous experience.

In the approach outlined by this report, the level of testing and the test limits vary depending on the lev-

el of risk that is acceptable to the owner. For example, in regions where occurrences of AAR are rare

or where the aggregate sources in use have a long history of good eld performance; it may be

reasonable to continue to rely on the previous eld history without subjecting the aggregates to

laboratory tests. However, in regions where AAR problems are not infrequent and where the

reactivity of aggregates are known to vary from source to source, it may be necessary to implement a

rigorous testing regime to establish aggregate reactivity and evaluate preventive measures. In the

report described here the level of prevention required is a function of the reactivity of the aggregate, the

nature of the exposure conditions, and the availability of alkali in the system.

Select aggregate source

Figure 1. Summary of the Various Stages in the Process of Evaluation

Field Evidence

Is it satisfactory?

Laboratory Tests

Is the aggregate

deleteriously reactive?

Type of Reaction

Is the expansion due to

ACR or ASR?

Alkali

-

Silica

Reactive

Take preventive

measures or do

not use

Alkali

-

Carbonate

Reactive

Avoid reactive

components or

do not use

Non

-

Reactive

Accept for use

No precautionary

measures

necessary

Select aggregate source

Yes

Yes

AC

Field Evidence

Is it satisfactory?

No

R

ASR

No

Laboratory Tests

Is the aggregate

deleteriously reactive?

Type of Reaction

Is the expansion due to

ACR or ASR?

Alkali

-

Silica

Reactive

Take preventive

measures or do

not use

Alkali

-

Carbonate

Reactive

Avoid reactive

components or

do not use

Yes

Yes

AC

No

No

ASR

R

Non

-

Reactive

Accept for use

No precautionary

3

3.0 Testing To Determine Aggregate Reactivity

Figure 2 shows a ow chart of the sequence of testing for this report when evaluating the reactivity of

an aggregate source. Selecting an appropriate preventive measure will be dealt with in the next

section. Interpreting the results from these aggregate tests is discussed at the end of this section (see

Section 3.6 below).

3.1. Use of Field Performance History

The long-term eld performance history of an aggregate can be established by conducting a survey of

existing structures that were constructed using the same aggregate source. As many structures as

practical should be included in the survey and these structures should, where possible, represent

different types of construction (pavements, sidewalks, curb and gutter, elements of bridges, barrier

walls and even non-transportation structures). The following information should be collected for each

structure:

• Age – structures should be at least 10 years old and preferably more than 15 years old as dam

age due to AAR can take more than ten years to develop.

• Cement content and alkali content of the cement used during construction.

• Use of pozzolans or slag during construction.

• Exposure condition – availability of moisture, use of deicing chemicals.

• Presence of symptoms of distress due to AAR or other causes.

.

Cores should be taken from a representative number of these structures and a petrographic examination

be conducted in accordance with ASTM C 856 to establish the following:

• The aggregate used in the structures surveyed is close in mineralogical composition to that of

the aggregate currently being produced.

• There is no evidence of damage due to AAR.

• The presence and quantity of y ash or slag.

If the results of the eld survey indicate that the aggregate is non-deleteriously reactive, the aggregate

may be used in new construction provided that the new concrete is not produced with a higher cement

alkali loading, lower amount of pozzolan or slag, or more aggressive exposure condition than the struc-

tures included in the survey.

There is a certain level of risk associated with accepting aggregates solely on the basis of eld perfor-

mance due to difculties in establishing unequivocally that the materials and proportions used more

than 10 to 15 years ago are similar to those to be used in new construction.

4

Petrographic Examination

Is the rock a quarried carbonate?

Accelerated Mortar Bar

Test, ASTM C 1260

Is 14-day expansion

> 0.10%?

Type of Reaction

†

Is the expansion due to

ACR or ASR?

Alkali-Carbonate

Reactive

Avoid reactive

components or

do not use

Alkali-Silica

Reactive

Take preventive

measures or do

not use

Non-Reactive

Accept for use

No precautionary

measures

necessary

No

ASR

ACR

No

Concrete Prism Test,

ASTM C 1293

Is 1-year expansion

> 0.040%?

No

Chemical Composition,

CSA A23.2-26A

Does the composition fall in

the region of potentially

alkali-carbonate reactive?

Yes

No

Yes

Yes

Yes

Petrographic Examination

Is the rock potentially reactive?

Yes

No

Field History

Is there a history of satisfactory

field performance?

No

Yes

Petrographic Examination

Is the rock a quarried carbonate?

Accelerated Mortar Bar

Test, ASTM C 1260

Is 14-day expansion

> 0.10%?

Type of Reaction

†

Is the expansion due to

ACR or ASR?

Alkali-Carbonate

Reactive

Avoid reactive

components or

do not use

Alkali-Silica

Reactive

Take preventive

measures or do

not use

Non-Reactive

Accept for use

No precautionary

measures

necessary

No

ASR

ACR

No

Concrete Prism Test,

ASTM C 1293

Is 1-year expansion

> 0.040%?

No

Chemical Composition,

CSA A23.2-26A

Does the composition fall in

the region of potentially

alkali-carbonate reactive?

Yes

No

Yes

Yes

Yes

Petrographic Examination

Is the rock potentially reactive?

Yes

No

Field History

Is there a history of satisfactory

field performance?

No

Yes

Figure 2. Sequence of Laboratory Tests for Evaluating Aggregate Reactivity

†

The type of reaction only needs to be determined after the concrete prism test if the aggregate being tested is a

quarried carbonate that has been identified as being potentially alkali-carbonate reactive by chemical

composition in accordance with test method CSA A23.2-26A

†

Note: The heavier dotted lines represent the preferred approach whereas the faint dotted lines represent a

higher risk approach.

5

If eld performance indicates that an aggregate source is deleteriously reactive, laboratory expansion

testing is required to determine the level of aggregate reactivity and to evaluate prevention measures.

3.2. Petrographic Assessment

Petrographic examination of aggregates should be conducted in accordance with ASTM C 295.

Petrography can reveal useful information about the composition of an aggregate, including the

identication and approximate quantication of reactive minerals. Petrography may be used to classify

an aggregate as potentially reactive, but expansion testing is required to determine the extent of the

reactivity and appropriate levels of prevention. Aggregates may be accepted as non-reactive solely on

the basis of petrography but there is certain level of risk associated with such a decision as some

reactive phases may not be detected by optical microscopy (e.g. nely dispersed opaline silica found in

some siliceous limestones). Where a trained petrographer is examining aggregates from well-known

and tested sources, it is acceptable to use petrography to classify the aggregate reactivity on a routine

basis. For example, in deposits where chert is known to be the only reactive component and where

testing has shown that the chert content needs to exceed 5% to cause deleterious reaction, it may be

justied to permit acceptance of an aggregate with less than say 3% chert on the basis of petrography.

In addition to looking for alkali-silica reactive minerals such as opal, chalcedony, cristobalite,

tridymite, strained and micro-crystalline quartz, and volcanic glass, petrographers should also be

vigilant as to the presence of mineralogical and textural features characteristic of alkali-carbonate

rocks. Deleterious alkali-carbonate reactive rocks are often characterized by a microscopic texture

consisting of dolomitic rhombs oating in a ne-grained matrix of calcite, quartz and clay. However,

there have been reports of deleterious ACR with rocks that do not exhibit this “classic” texture (Ozol,

2006).

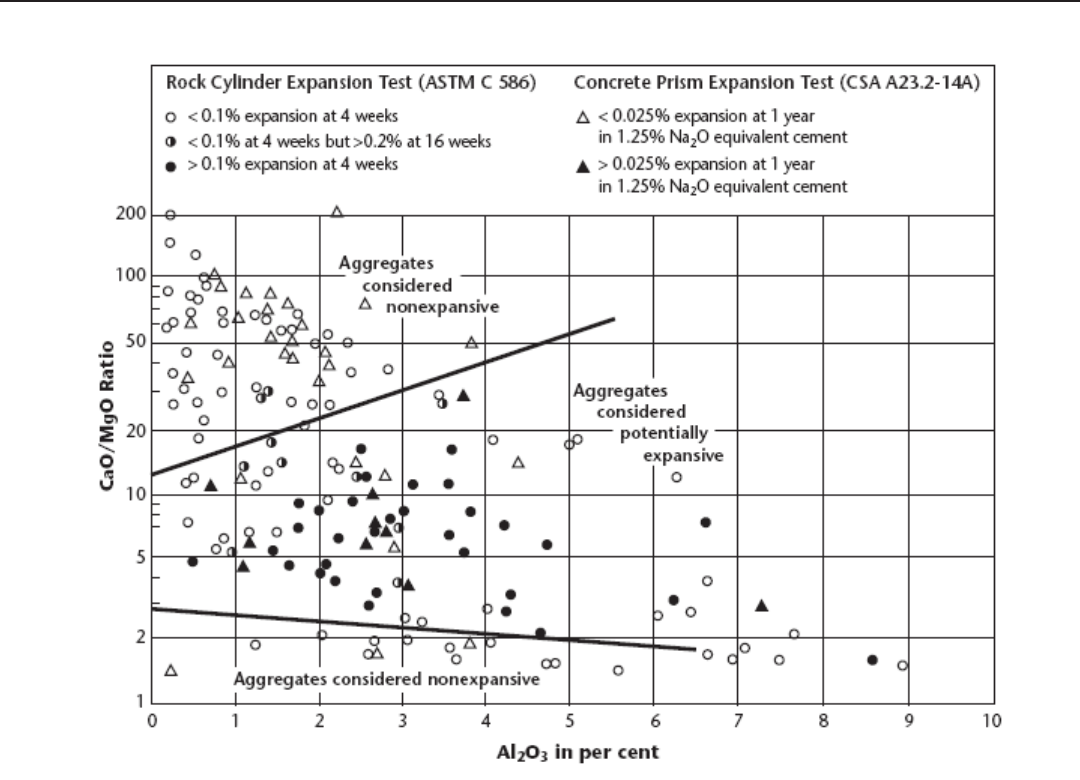

3.3. Determination of Potential Alkali-Carbonate Reactive Rocks by Chemical Composition,

CSA A23.2-26A

If the aggregate being assessed is a quarried carbonate rock, the potential for alkali-carbonate reaction

may be assessed on the basis of its chemical composition (Rogers, 1986). This is the basis for the test

method CSA A23.2-26A .² This test involves the determination of the lime (CaO), magnesia (MgO)

and alumina (Al

2

O

3

) content of the rock, and determining where the composition of the rock falls on a

plot of CaO/MgO ratio versus the Al

2

O

3

content, as shown in Figure 3. If the composition falls in the

range of “aggregates considered to be potentially expansive,” the aggregate is potentially

alkali-carbonate reactive. Such aggregates must be tested using the ASTM C 1293 (concrete prism

test) as ASTM C 1260 (accelerated mortar bar test) is not suitable for detecting alkali-carbonate

reaction.

²CSA is the Canadian Standards Association. CSA Standards such as A23.2 Method of Test and Standard Practices for Concrete can be

found at www.csa.ca

6

Figure 3. Using Chemical Composition as a Basis for Determining Potential Alkali-Carbonate Reactivity of

Quarried Carbonates (from CSA A23.2-26A)

3.4. Accelerated Mortar Bar Test, ASTM C 1260

If the aggregate is not a quarried carbonate or it is a quarried carbonate with a composition that falls

outside of the region of “aggregates considered to be potentially reactive” in Figure 3 when tested in

accordance with CSA A23.2-26A, the next step is to test the aggregate in accordance with ASTM C

1260.

Coarse aggregates for this test have to the crushed to sand size (< 5 mm) and then washed and graded

to meet the grading requirements of the test. Sands have to be washed and graded to meet the same

grading requirements. The test is intended to evaluate coarse and ne aggregates separately, and should

not be used to evaluate job combinations of coarse and ne aggregates.

In this test, mortar bars are produced with the aggregate being evaluated and at the age of two days the

bars are immersed into a solution of 1 M NaOH maintained at a temperature of 176oF (80oC) and the

length change of the bars is monitored. If the mortars do not expand by more than 0.10% after 14 days

immersion in this solution, the aggregate is considered non-deleteriously reactive. If the mortar bar

expands by more that 0.10% at 14 days, the aggregate is considered to be potentially reactivity and its

reactive should be conrmed in ASTM C 1293 (concrete prism test).

7

3.5. Concrete Prism Test, ASTM C 1293

The concrete prism test is suitable for evaluating all aggregate types and is considered to be the most

reliable laboratory test for predicting eld performance of aggregates. If the aggregate being tested is

a coarse aggregate it is blended with a non-reactive ne aggregate and vice-versa, and the coarse-ne

aggregate combination is used to produce concrete prisms with a specied high alkali loading. The test

is not intended for use with specic job combinations of coarse and ne aggregate, however, it is

generally considered acceptable to do this, but the results are not applicable if either the coarse or ne

aggregate is changed during the job.

The prisms are stored over water in sealed containers at 100oF (38oC) and the length change is moni-

tored periodically. If the prisms do not expand by more than 0.04% after 1 year, the aggregate is con-

sidered non-deleteriously reactive and may be used in concrete with no further testing (for AAR). If

the prism expands by more that 0.04% at 1 year, the aggregate is considered to be potentially reactive

and preventive measures are required if the aggregate is to be used in concrete construction.

If the aggregate tested was a quarried carbonate rock with a chemical composition that fell within the

region of “aggregates considered to be potentially reactive,” the concrete prisms must be examined to

determine whether alkali-carbonate reaction contributed to the expansion.³ If damaging ACR is

detected, either in isolation or in combination with ASR, the rock should not be used in concrete

without selective quarrying or aggregate beneciation to remove the reactive components.

3.6. Interpretation of Results from Laboratory Tests

Figure 2 shows dotted lines from the boxes marked “Field History”, “Petrographic Examination”, and

“Accelerated Mortar Bar Test” to the box marked “Non-Reactive” as there is an element of risk

associated with accepting aggregates solely on the basis of these tests. With eld history it is usually

difcult to rmly establish that the materials and conditions to be used in a new project are the same as

those used in a structure that is more than 10 to 15 years old. With some aggregates it may not be

possible to identify reactive constituents by petrographic examination.

The accelerated mortar bar test (AMBT) is generally recognized as a relatively severe test and it is well

established that it identies as deleteriously reactive many aggregate sources that have a history of

satisfactory eld performance and that perform well in the concrete prism test (CPT);

4

that is the CPT

identies the same aggregate as non-deleteriously reactive. For this reason, results from the accelerated

mortar bar test should not be used to reject an aggregate. If an aggregate fails the AMBT (expansion

> 0.10% at 14 days) its reactivity should be conrmed by testing using the CPT. If the results of the

AMBT and CPT are in disagreement, the results of the CPT shall prevail.

³The determination of the extent to which the alkali-carbonate reaction contributed to the expansion of the concrete should be con-

ducted by an expert with experience of ACR. Methods used might include a petrographic examination of the concrete (ASTM C 856),

accelerated microbar testing of the aggregate (Lu et al., 2004), and/or rock cylinder expansion tests (ASTM C 586) conducted on

samples of rock from the quarry. The ASTM C 1105 version of the concrete prism test for alkali-carbonate rock reaction may also be

used but the alkali content of the concrete should be kept sufciently low to ensure that expansion due to alkali-silica reaction is elimi-

nated during the test. Keeping the alkali content below 1.8 kg/m

3

(3.0 lb/yd

3

) Na

2

Oe should be sufcient for this purpose.

4

The term “false positive” is used to describe the case where a test method incorrectly identies an aggregate as deleteriously reactive.

Similarly, “false negative” describes the case where a test wrongly identies an aggregate as being non-deleteriously reactive.

8

Until recently it was assumed that aggregates that passed the AMBT (expansion ≤ 0.10% at 14 days)

were most likely to pass the CPT (expansion ≤ 0.04% at 1 year), and such aggregates could be accepted

for use in concrete without the need for conrmatory testing using the CPT. However, there appears

to be an increasing number of coarse aggregates that pass the AMBT and fail the CPT (Folliard et al.

2006) and this is somewhat disconcerting for specications that permit the use of aggregates passing

the AMBT with no further testing (that is no requirements for CPT).

5

Consequently, there is a risk as-

sociated with accepting an aggregate solely on the basis of the results from the AMBT.

In Figure 2, the AMBT is shown with a broken line as there is the possibility of incorrectly identify-

ing a deleteriously-reactive aggregate as being non-deleteriously-reactive using this test method. The

most reliable approach for determining aggregate reactivity is to use the CPT as the expansion test for

all cases (that is to exclude the AMBT from the evaluation process). However, it is recognized that the

long duration of the CPT makes it impractical for use in many circumstances and there is a need for

a more rapid test. Despite its limitations, the AMBT is probably the most viable accelerated test cur-

rently in use.

3.7. Risk Evaluation

The risk of AAR-damage occurring due to a failure to detect deleteriously reactive aggregate can be

reduced by implementing routine testing using petrography and/or laboratory expansion tests. Increas-

ing the complexity and frequency of testing will result in lower risks but higher costs. For example,

frequent petrographic and concrete prism testing of all aggregate sources may reduce the risk of failing

to identify deleteriously reactive aggregates to a negligible level, but the costs associated with this level

of testing may not be justied in a region where there are few cases of AAR and where most aggregate

sources have a good eld performance history. It is incumbent on the owner to dene what level of risk

is acceptable and thus determine the type and frequency of testing.

3.8. Other Test Methods

There are many other test methods for evaluating the reactivity of aggregates and a full discussion of

these tests is beyond the scope of this report. One of the more promising tests is an accelerated version

of the CPT, which is conducted at 140oF (60oC) to accelerate the reaction. A detailed discussion of

these tests can be found elsewhere (Thomas et al. 2006).

4.0 Preventing Damaging Expansion in Concrete Containing Alkali-Silica Reactive

Aggregates

This report provides two approaches for selecting preventive measures. In the rst approach, the

performance of the preventive measure is tested in combination with the reactive aggregate using either

5

It has been proposed to extend the duration of this test and to use an expansion limit of 0.10%, or even, 0.08% after 28 days immersion in 1 M

NaOH at 176 °F (80 °C). This more onerous requirement should be adopted only when it can be demonstrated that extension of the test period is

required to capture aggregates that have been identied as being deleteriously reactive either by concrete prism testing or eld performance. The ex-

tended test duration should not be applied across the board to all aggregates as this will result in an unacceptable number of cases where the acceler-

ated mortar bar test results in false positives (that is the test wrongly identies aggregates as deleteriously reactive). It should be noted that extending

the test duration does not capture all of the aggregates that have been found to pass the AMBT but fail the CPT.

9

the CPT or the AMBT. This approach is suitable for selecting the appropriate level of SCM’s or lithi-

um nitrate admixtures. The second is a prescriptive approach where the preventive measure is selected

on the basis of the reactivity of the aggregate, the nature of structure and its exposure, the required

service life, and the availability of alkalis in the system. This approach is suitable for selecting the ap-

propriate level of SCM and/or the maximum alkali content of the concrete.

The preventive measures determined by either performance testing or prescription using this report

will generally reduce the risk of expansion due to ASR to an acceptable level for most highway ap-

plications. However, it should be noted that the level of prevention arrived at by following this report

may not be sufcient for certain critical structures such as hydraulic dams or power plants where ASR

expansion of any level cannot be tolerated.

4.1. Performance Testing Using the Concrete Prism Test (CPT)

The ability of SCM’s such as y ash, slag, silica fume and natural pozzolans, or of chemical admix-

tures, such as lithium compounds, to control deleterious expansion with a reactive aggregate can be

evaluated using a modied version of the concrete prism test, ASTM C 1293. When testing SCM’s, the

total cementitious content is maintained at 708 lb/yd

3

(420 kg/m

3

), but the portland cement is partially

replaced with the desired amount of the SCM (or combination of SCM’s) under investigation. The al-

kali content of the portland cement component of the mix only is raised to 1.25% Na2Oe.

6

It is prudent

to conduct a number of tests using varying levels of SCM(s) to optimize the proportions in terms of

meeting the expansion criteria. The test duration for evaluating preventive measures is two years and

the expansion criterion used to demonstrate that the combination of SCM and reactive aggregate is suit-

able for use in concrete construction is expansion ≤ 0.04% at 2 years.

The only lithium compound included in this report is an aqueous solution of lithium nitrate.

7

When

testing lithium nitrate solution the procedure in ASTM C 1293 is followed with the following excep-

tions:

The alkali content of the portland cement is raised to 1.25% Na

2

Oe.

The desired quantity of lithium nitrate solution is added to the mix water prior to mixing. It is prudent

to conduct a number of tests using varying amounts of lithium to determine the minimum “safe” level

required to sufciently suppress expansion.

8

The amount of water contained in the lithium nitrate solution should be included in the calculation of W/

CM. In other words, this amount of water should be subtracted from the mix water content required for

the same mix without lithium.

6

The expansion of concrete prisms produced with cement alkalis raised to 1.25% Na

2

Oe provides a reliable prediction of the eld expansion of concrete

produced with cement with alkalis up to 1.0% Na

2

Oe. If the cement to be used in the eld has an alkali content above 1.00% Na

2

Oe, this same cement

should be used for the concrete prism test and the alkalis should be raised by 0.25% Na

2

Oe by the addition of NaOH to the mix water.

7

At the time of writing, the only commercially available products were all solutions containing 30% LiNO

3

.

8

The published literature indicates that the level of lithium required increases as the concentration of the other alkalis (Na+K) in the system increases.

For many aggregates, deleterious expansion appears to be prevented when the lithium-to-sodium-plus-potassium-molar ratio, [Li]/ [Na+K] ≥ 0.74. For

a 30%-solution of LiNO

3

, the molar ratio of 0.74 is achieved when the dose of lithium is equal to 0.55 gal LiNO3 solution per lb Na2Oe (4.6 L LiNO

3

solution per kg Na2Oe). The alkalis added to the mix water as NaOH should be included in the calculation of the lithium-to-sodium-plus-potassium-

molar ratio.

10

The test is extended to two years and the expansion criterion used to demonstrate that the combination

of lithium and reactive aggregate is suitable for use in concrete construction is expansion ≤ 0.04%

at 2 years.

4.2. Performance Testing Using the Accelerated Mortar Bar Test (AMBT)

Before the accelerated mortar bar test (AMBT) can be used to determine the performance of a specic

SCM-aggregate or lithium-aggregate combination, it must rst be demonstrated that the aggregate

being evaluated responds well to the accelerated test. This requires a comparison of the results from the

AMBT and the CPT test for the aggregate being used (without preventive measures). After subjecting

the aggregate to both tests, the results are plotted on Figure 4. Provided the data fall within the region

indicated in Figure 4, the AMBT can be used to determine the efcacy of both SCM’s and lithium nitrate.

The AMBT and CPT should be compared every two years unless the results of petrography or other tests

indicate a signicant change in the composition of the material in the quarry, in which case new tests

should be commenced immediately.

When testing the SCM in the AMBT, the modied version of the test, ASTM C 1567, should be used; this

test was developed specically for “determining the potential alkali-silica reactivity of combinations of

cementitious materials and aggregates.” Combinations of cementitious materials and aggregates will be

deemed acceptable for use if the expansion ≤ 0.10% after 14 days immersion in 1 M NaOH.

9

Note: this

test method is not suitable for evaluating SCM’s with high levels of alkalis (y ash with > 4.5% Na

2

Oe,

and slag and silica fume with > 1.0% Na

2

Oe) and such materials should be evaluated using the concrete

prism test.

9

If it has been determined that an extended test duration of 28 days in 1M NaOH and a lower expansion limit of 0.08% is required to correctly identify

the aggregate as deleteriously reactive then the same requirements should be used to evaluate the preventive measures.

11

0.0

0.2

0.4

0.6

0.8

1.0

0 0.1 0.2 0.3 0.4 0.5 0.6

Expansion in AMBT at 14 Days (%)

If AMBT vs CPT data fall

within this range - the AMBT

may be used to evaluate

preventive measures

Expansion in CPT at 1 Year (%)

Figure 4. Comparison of AMBT and CPT Data for the Purpose of Determining Whether the AMBT is

Suitable for Evaluating Preventive Measures with a Specic Aggregate

When using the AMBT to determine the lithium dose required with a specic aggregate the approach

proposed by Tremblay et al. (2008) will be used; the procedure is as follows:

1. Test the aggregate using the standard AMBT (ASTM C 1260). Extend the duration of the test

such that the mortar bars are exposed to 1M NaOH at 80oC (178oF) for a period of 28 days. Let E1 =

expansion of bars without lithium at 28 days.

2. Test the aggregate in a modied version of the AMBT. In this test add sufcient lithium

nitrate to the mortar bar mixture and the soak solution to achieve lithium-to-alkali molar ratios of [Li]/

[Na+K] = 0.74 in the mortar and [Li]/ [Na+K] = 0.148 in the soak solution. Conduct the rest of the test

in accordance with ASTM C 1260 extending the period in 1 M NaOH to 28 days. Let E2 = expansion

of bars with lithium at 28 days.

3. If (E

2

– E

1

)/E

1

< 0.1 then use the following lithium-to-alkali molar ratio:

(Eq.1)

LA=[LI]/[Na + K] = 1.0 + 0.7X [(E

2

- E

1

)/E

1

]

Where LA is the lithium-to-sodium-plus-potassium molar ratio. The amount of 30%-LiNO

3

solution

required in the concrete mix is then 0.55 x LA/0.74 gal of lithium solution per lb of Na

2

Oe in the con-

crete mixture (or 4.6 x LA/0.74 liters of lithium solution per kg of Na

2

Oe.

4. If (E

2

– E

1

)/E

1

≥ 0.1 then use the concrete prism test to determine the lithium content required

(see Section 5.2).

12

4.3. Prescriptive Approach for Selecting Preventive Measures

The level of prevention is determined by considering the class, size and exposure condition of the

structure, the degree of aggregate reactivity, and the level of alkalis from the portland cement (when

SCM’s are used as preventive measures). This approach is similar to that developed in Canada (CSA

A23.2-27A) and in Europe (RILEM TC191-ARP: AAR-7).

4.3.1. Degree of Aggregate Reactivity

The degree of alkali-silica reactivity of an aggregate is determined by testing the aggregate in the CPT

and using the expansion value at one-year. Aggregate-reactivity classes are given in Table 1.

Table 1. Classification of Aggregate Reactivity

Aggregate-

Reactivity Class

R0

R1

R2

R3

Description of Aggregate

Reactivity

Non-reactive

Moderately reactive

Highly reactive

Very highly reactive

One-Year Expansion

in CPT (%)

< 0.040

0.040 - 0.120

0.120 - 0.240

> 0.240

If data from the CPT are not available, the aggregate may be considered as very highly reactive (R3).

Where the coarse and ne aggregates are of different reactivity, the level of prevention should be se-

lected for the most reactive aggregate.

4.3.2. Level of ASR Risk

The risk of ASR occurring in a structure is determined by considering the aggregate reactivity and the

exposure conditions using Table 2.

13

Table 2. Determining the Level of ASR Risk

Size and exposure conditions

Aggregate-Reactivity Class

R0 R1 R2 R3

Non-massive

†

environment

2

concrete in a dry

Level 1 Level 1 Level 2 Level 3

Massive

†

elements in a dry

††

environment

Level 1 Level 2 Level 3 Level 4

All concrete exposed to humid

air, buried or immersed

Level 1 Level 3 Level 4 Level 5

All concrete exposed to alkalis in

service

†††

Level 1 Level 4 Level 5 Level 6

†

A massive element has a least dimension > 3 ft (0.9 m)

††

A dry environment corresponds to an average ambient relative humidity lower than 60%, normally

only found in buildings

†††

Examples of structures exposed to alkalis in service include marine structures exposed to seawater

and highway structures exposed to deicing salts (e.g. NaCl) or anti-icing salts (e.g. potassium acetate,

sodium formate, etc.)

4.3.3. Determination of the Level of Prevention

The level of prevention required is determined from Table 3 by considering the risk of ASR

from Table 2 together with the class of structure from Table 4.

Table 3. Determining the Level of Prevention

Level of ASR

Classification of Structure (Table 4)

Risk (Table 4)

S1 S2 S3 S4

Risk Level 1 V V V V

Risk Level 2 V V W X

Risk Level 3 V W X Y

Risk Level 4 W X Y Z

Risk Level 5 X Y Z ZZ

Risk Level 6 Y Z ZZ

††

††

It is not permitted to construct a Class S4 structure (see Table 4) when the risk of ASR

is Level 6. Measures must be taken to reduce the level of risk in these circumstances.

14

Table 4. Structures Classified on the Basis of the Severity of the Consequences Should ASR

†

Occur (Modified

for Highway Structures from RILEM TC 191-ARP)

Class

Consequences of

ASR

Acceptability of

ASR

Examples

††

S1

Safety, economic or

environmental

consequences small

or negligible

Some

deterioration

from ASR may

be tolerated

Non-load-bearing elements inside buildings

Temporary structures (e.g. < 5 years)

S2

Some safety,

economic or

environmental

consequences if

major deterioration

Moderate risk

of ASR is

acceptable

Sidewalks, curbs and gutters

Service-life < 40 years

Pavements

S3

Significant safety,

economic or

environmental

consequences if

minor damage

Minor risk of

ASR acceptable

Culverts

Highway barriers

Rural, low-volume bridges

Large numbers of precast elements where

economic costs of replacement are severe

Service life normally 40 to 75 years

S4

Serious safety,

economic or

environmental

consequences if

minor damage

ASR cannot be

tolerated

Major bridges

Tunnels

Critical elements that are very difficult to

inspect or repair

Service life normally > 75 years

†

Note: this table does not consider the consequences of damage due to ACR. This protocol does not permit the use

of alkali-carbonate aggregates

††

The types of structures listed under each Class are meant to serve as examples. Some owners may decide to use

their own classification system. For example, sidewalks and culverts may be placed in the S3 Class is some

jurisdictions.

4.3.4. Identication of Preventive Measures

Option 1 – Limiting the Alkali Content of the Concrete

Damaging alkali-silica reaction can be prevented by limiting the alkali content of the concrete. Maxi-

mum permissible alkali contents are given in Table 5. The alkali content of concrete is calculated on

the basis of the alkali contributed by the portland cement alone.

15

Table 5. Maximum Alkali Contents to Provide Various Levels of Prevention

Prevention

Level

Maximum alkali content of concrete (Na

2

Oe)

lb/yd

3

kg/m

3

V No limit

W 5.0 3.0

X 4.0 2.4

Y 3.0 1.8

Z

†

Table 7

ZZ

†

†

SCM’s must be used in Prevention levels Z and ZZ.

Option 2 – Using Supplementary Cementing Materials (SCM)

Damaging alkali-silica reaction can be prevented by using a sufcient quantity of a suitable supplemen-

tary cementing material (SCM) such as y ash, slag, silica fume or natural pozzolan. Table 6 provides

minimum replacement levels for Class F y ash with less than 18% CaO and meeting the requirements

of ASTM C 618, silica fume with more than 85% SiO

2

and meeting the requirements of ASTM C 1240,

and slag meeting the requirements of ASTM C 989. Class C y ashes or Class F y ashes with more

than 18% CaO are not covered by these prescriptive measures; the ability of these materials to control

ASR with a particular reactive aggregate should be determined by performance testing (see sections 4.1

and 4.2).

Many natural pozzolans such as metakaolin, calcined clays and shales, and volcanic ash have been

shown to be effective in controlling expansion due to ASR. However, no prescriptive measures are

provided for natural pozzolans in Table 6 as this class of materials covers a wide variety of pozzolan

types with a broad range of properties. When natural pozzolans are to be used to control ASR, the ef-

cacy of a particular aggregate-pozzolan combination should be determined by performance testing

(see sections 4.1 and 4.2). Information on natural pozzolans can be found in ACI 232.1R Use of Raw

or Processed Natural Pozzolans in Concrete.

16

Table 6. Minimum Levels of SCM to Provide Various Levels of Prevention

Type of SCM

Alkali level

of SCM

(% Na

2

Oe)

Minimum Replacement Level

†† (% by mass)

Level W Level X Level Y Level Z Level ZZ

Fly ash

(CaO ≤ 18%)

< 3.0 15 20 25 35

Table 7

3.0 – 4.5 20 25 30 40

Slag < 1.0 25 35 50 65

Silica Fume†

(SiO

2

> 85%)

< 1.0

1.2 x LBA

or

2.0 x KGA

1.5 x LBA

or

2.5 x KGA

1.8 x LBA

or

3.0 x KGA

2.4 x LBA

or

4.0 x KGA

†The minimum level of silica fume (as a percentage of cementing material) is calculated on the basis of the alkali

(Na

2

Oe) content of the concrete contributed by the portland cement and expressed in either units of lb/yd

3

(LBA in

Table 6) or kg/m

3

(KGA in Table 6). LBA is calculated by multiplying the cement content of the concrete in lb/yd

3

by the alkali content of the cement divided by 100. For example, for a concrete containing 500 lb/yd

3

of cement with

an alkali content of 0.81% Na

2

Oe the value of LBA = 500 x 0.81/100 = 4.05 lb/yd

3

. For this concrete, the minimum

replacement level of silica fume for Level Y is 1.8 x 4.05 = 8.1%. KGA is calculated by multiplying the cement

content of the concrete in kg/m

3

by the alkali content of the cement divided by 100. For example, for a concrete

containing 300 kg/m

3

of cement with an alkali content of 0.91% Na

2

Oe the value of KGA = 300 x 0.91/100 = 2.73

kg/m

3

. For this concrete, the minimum replacement level of silica fume for Level X is 2.5 x 2.73 = 6.8%.

Regardless of the calculated value, the minimum level of silica fume shall not be less than 7% when it is the only

method of prevention.

†† Note: the use of high levels of SCM in concrete may increase the risk of problems due to deicer salt scaling if the

concrete is not properly proportioned, finished and cured.

When two or more SCM’s are used together to control ASR, the minimum replacement levels given

in Table 6 for the individual SCM’s may be reduced provided that the sum of the parts of each SCM is

greater than or equal to one. For example, when silica fume and slag are used together, the silica fume

level may be reduced to one-third of the minimum silica fume level given in the table provided that the

slag level is at least two-thirds of the minimum slag level.

The minimum replacement levels in Table 6 are appropriate for use with portland cements of moder-

ate to high alkali contents (0.7 to 1.0 % Na

2

Oe). Table 7 provided recommendations for adjusting

the level of SCM when the alkali content of the portland cement is above or below this range. Where

SCM’s are combined with lower alkali cements (< 0.7% Na

2

Oe) it is probably safe to adopt the value

of the minimum replacement level for the next prevention level down. For example, if slag is to be

used in prevention level Y with a low-alkali cement, the level of slag can be reduced to the level speci-

ed for prevention level X (35%). The replacement levels should not be below those given in Table

6 for prevention level W, regardless of the alkali content of the portland cement. Similarly, if higher

alkali cements (> 1.0% Na

2

Oe) are used together with SCMs, the replacement level of SCM should be

increased to that required for the next prevention level up. For example, if slag is to be used in preven-

tion level Y with a high-alkali cement, the level of slag should be increased to the level specied for

prevention level Z (65%). This report does not provide guidance for using preventive measures with

reactive aggregates when the alkali content of the portland cement exceeds 1.25% Na

2

Oe.

17

Table 7. Adjusting the Minimum Level of SCM Based on the Alkali Content

of the Portland Cement

Cement Alkalis Level of SCM

(% Na

2

Oe)

< 0.70

Reduce the minimum amount of SCM given in

Table 6 by one prevention level†

0.70 to 1.00 Use the minimum levels of SCM given in Table 6

> 1.00

Increase the minimum amount of SCM given in

Table 6 by one prevention level

> 1.25 No guidance is given

†The replacement levels should not be below those given in Table 6 for prevention level W, regardless of the alkali

content of the portland cement.

Option 3 – Controlling the Alkali Level of Concrete and using SCMs when Exceptional Levels of Prevention

are Required (Levels Z and ZZ)

Where extreme levels of prevention are required, a combination of Options 1 and 2 may be required. This ap-

proach requires that a minimum level of SCM is used and that a maximum limit is placed on the alkali content

of the concrete contributed by the portland cement. Options for Prevention Levels Z and ZZ are given in Table

8.

Table 8. Using SCM and Limiting the Alkali Content of the Concrete to Provide Exceptional Levels of

Prevention

Prevention

Level

SCM as sole prevention Limiting concrete alkali content plus SCM

Minimum SCM level

Maximum alkali content,

lb/yd

3

(kg/m

3

)

Minimum SCM level

Z

SCM level shown for

Level Z in Table 7

3.0 (1.8)

SCM level shown for

Level Y in Table 6

ZZ Not permitted 3.0 (1.8)

SCM level shown for

Level Z in Table 6

18

5.0 SUMMARY

This document describes a report for determining the reactivity of concrete aggregates and selecting

appropriate measures for preventing deleterious expansion in new concrete construction. It is recom-

mended that the following sequence of testing is followed to determine aggregate reactivity: consid-

eration of eld performance history, petrographic examination, accelerated mortar bar testing and

concrete prism testing. Some agencies may adopt one or more of these test procedures depending on

prior experience with ASR and the acceptable level of risk of ASR in new construction. Appropriate

preventive measures can be selected either by performance testing using the accelerated mortar bar test

or concrete prism test, or by using prescribed measures which have been developed based on previous

experience and published research data. The level of prevention prescribed is a function of the class of

the structure, the reactivity of the aggregate, the alkali content of the portland cement, the composition

of the material used for prevention, and the exposure conditions. This report is not aimed at completely

eliminating the possibility of ASR expansion occurring in new construction but it does provide various

approaches for minimizing the risk of ASR to a level acceptable to the owner.

19

6.0 REFERENCES

American Concrete Institute (ACI), “Use of Raw of Processed Natural Pozzolans in Concrete,” ACI

221.1R, 2000.

American Standards for Testing and Materials (ASTM), “Standard Guide for Petrographic Examination

of Aggregates for Concrete,” ASTM International, ASTM C295.

American Standards for Testing and Materials (ASTM), “Standard Test Method for Potential Alkali

Reactivity of Carbonate Rocks as Concrete Aggregates (Rock-Cylinder Method),” ASTM International,

ASTM C586.

American Standards for Testing and Materials (ASTM), “Standard Specication for Coal Fly Ash and

Raw or Calcined Natural Pozzolan for Use in Concrete,” ASTM International, ASTM C618.

American Standards for Testing and Materials (ASTM), “Standard Practice for Petrographic Exami-

nation of Hardened Concrete,” ASTM International, ASTM C856, Annual book of ASTM Standards,

Section Four, Vol. 04.02 Concrete and Aggregates, pp. 434-450, 2003.

American Standards for Testing and Materials (ASTM), “Standard Specication for Ground Granulated

Blast-Furnace Slag for Use in Concrete and Mortars,” ASTM International, ASTM C989.

American Standards for Testing and Materials (ASTM), “Standard Test Method for Length Change of

Concrete Due to Alkali-Carbonate Rock Reaction,” ASTM International, ASTM C1105.

American Standards for Testing and Materials (ASTM), “Standard Specication for Silica Fume Used

in Cementitious Mixtures,” ASTM International, ASTM C1240.

American Standards for Testing and Materials (ASTM), “Standard Test Method for Potential Alkali

Reactivity of Aggregates (Mortar-Bar Method),” ASTM International, ASTM C1260.

American Standards for Testing and Materials (ASTM), “Standard Test Method for Determination of

Length Change of Concrete Due to Alkali-Silica Reaction,” ASTM International, ASTM C1293.

American Standards for Testing and Materials (ASTM), “Standard Test Method for Determining the

Potential Alkali-silica Reactivity of Combinations of Cementitious Materials and Aggregates,” ASTM

International, ASTM C1567.

Canadian Standards Association (CSA), “Determination of Potential Alkali-Carbonate Reactivity of

Quarried Carbonate Rocks by Chemical Composition,” CSA A23.2-26A, Canadian Standards Associa-

tion, Mississauga, Ontario, Canada.

Canadian Standards Association (CSA), “Standard Practice to Identify Degree of Alkali-Aggregate Re-

activity of Aggregates and to Identify Measures to Avoid Deleterious Expansion in Concrete (2000a),”

CSA A23.2-27A, Canadian Standards Association, Mississauga, Ontario, Canada, 2000.

20

Folliard, K.J., Barborak, R., Drimalas, T., Du, L., Garber, S., Ideker, J., Ley, T., Williams, S., Juenger,

M., Thomas, M.D.A., and Fournier, B., “Preventing ASR/DEF in New Concrete: Final Report,” The

University of Texas at Austin, Center for Transportation Research (CTR), CTR 4085-5, 2006.

Lu, D.Y., Fournier, B. and Grattan-Bellew, P.E., “Evaluation of the Chinese Accelerated Test for Alkali-

Carbonate Reaction,” Proceedings of the 12th International Conference on Alkali-Aggregate Reaction

in Concrete, Beijing (China), International Academic Publishes, World Publishing Corporation, ISBN

7-5062-7033-1, Tang, M.S. and Deng, M. Editors, Vol. 1, pp. 386-392, Oct 15-19 2004.

Nixon, P.J., and Sims, I., “Alkali-reactivity and Prevention – Assessment, Specication, and Diagnosis

of Alkali-reactivity,” International Union of Laboratories and Experts in Construction Materials, Sys-

tems and Structures (RILEM), International Specication to Minimise Damage from Alkali Reactions

in Concrete: Part 1 Alkali-Silica Reaction, RILEM TC 191-ARP AAR-7.1, 2006.

Ozol, M.A., “Alkali-carbonate Rock Reaction,” Signicance of Tests and Properties of Concrete, STP

169D, Chapter 23, American Society of Testing and Materials, West Conshohocken, PA, pp. 410-424,

2006.

Rogers, C.A., “Evaluation for the Potential for Expansion and Cracking of Concrete Caused by the

Alkali-carbonate Reaction,” Cement, Concrete and Aggregates, Vol. 8, No. 1, pp. 13-23, 1986.

Thomas, M.D.A., Fournier, B., Folliard, K., Ideker, J. and Shehata, M., “Test Methods for Evaluating

Preventive Measures for Controlling Expansion due to Alkali-silica Reaction in Concrete,” Cement and

Concrete Research, Vol. 36 (10), pp. 1842-1856, 2006.

Tremblay, C., Berube, M-A., Fournier, B., Thomas, M.D.A. and Folliard, K.J., “Use of the Accelerated

Mortar Test to Evaluate the Effectiveness of LiNO3 Against Alkali-silica Reaction Part 2: Comparison

With Results from the Concrete Prism Test,” Accepted for publication, Cement and Concrete Research,

March 2008.

21

FHWA-HIF-09-001