THE ENVIRONMENT

(PROTECTION) RULES, 1986

(As amended to date)

The Environment (Protection) Rules, 1986

389

THE ENVIRONMENT (PROTECTION) RULES, 1986

MINISTRY OF ENVIRONMENT AND FORESTS

(Department of Environment, Forest and Wildlife)

NOTIFICATION

New Delhi, the 19

th

November, 1986

1

S.O. 844(E) - In exercise of the powers conferred by sections 6 and 25 of the

Environment (Protection) Act, 1986 (29 of 1986), the Central Government hereby makes

the following rules, namely:-

1. SHORT TITLE AND COMMENCEMENT

(i) These rules may be called the Environment (Protection) Rules, 1986.

(ii) They shall come into force on the date of their publication in the Official

Gazette.

2. DEFINITIONS

In these rules, unless the context otherwise requires,-

(a) "Act" means the Environment (Protection) Act, 1986 (29 of 1986);

2

[(aa) "areas" means all areas where the hazardous substances are handled;]

(b) "Central Board" means the Central Pollution Control Board constituted under

section 3 of the Water (Prevention and Control of Pollution) Act, 1974 (6 of

1974);

(c) "Form" means a form set forth in Appendix A to these rules;

(d) "Government Analyst" means a person appointed or recognized as such under

section 13;

(e) "person" in relation to any factory or premises means a person or occupier or

his agent who has control over the affairs of the factory or premises and includes

in relation to any substance, the person in possession of the substance.

1

As published in Gazette of India, Extraordinary, Part II 3(ii), dt.19.11.1986.

2

Clauses (aa), (ee) and (ff) inserted by Notification NO. G.S.R. 931(E) dated 27.10.89 published in the Gazette No.

564 dated 27.10.89. These rules are referred to as Principal Rules in all Notifications beginning with S.O. 32(E)

published in the Gazette No. 66 dated 16.2.87.

The Environment (Protection) Rules, 1986

390

1

[(ee) "prohibited substance" means the substance prohibited for handling;]

(f) "recipient system" means the part of the environment such as soil, water, air

or other which receives the pollutants;

1

[(ff) "restricted substance" means the substance restricted for handling;]

(g) "section" means a section of the Act;

(h) "Schedule" means a Schedule appended to these rules;

(i) "Standards” means standards prescribed under these rules;

(j) "State Board" means a State Pollution Control Board constituted under section

4 of the Water (Prevention and Control of Pollution) Act, 1974 (6 of 1974) or a

State Pollution Control Board constituted under section 5 of the Air (Prevention

and Control of Pollution) Act, 1981 (14 of 1981);

3. STANDARDS FOR EMISSION OR DISCHARGE OF ENVIRONMENTAL

POLLUTANTS

(1) For the purpose of protecting and improving the quality of the environment

and preventing and abating environmental pollution, the standards for emission or

discharge of environmental pollutants from the industries, operations or processes shall

be as specified in

2

[Schedule I to IV].

(2) Notwithstanding anything contained in sub-rule (1),the Central Board or a

State Board may specify more stringent standards from those provided in

3

[Schedule I to

IV] in respect of any specific industry, operation or process depending upon the quality

of the recipient system and after recording reasons therefore in writing.

4

[(3) The standards for emission or discharge of environmental pollutants

specified under sub-rule (1) or sub-rule (2) shall be complied with by an industry,

operation or process within a period of one year of being so specified.]

1

Clauses (aa), (ee) and (ff) inserted by Notification NO. G.S.R. 931(E) dated 27.10.89 published in the Gazette No.

564 dated 27.10.89. These rules are referred to as Principal Rules in all Notifications beginning with S.O. 32(E)

published in the Gazette No. 66 dated 16.2.87.

2

Substituted by notification G.S.R 422(E) dated 19.5.1993, published in the Gazette No. 174 dated 19.5.1993.

3

Substituted ibid

4

The sub-rule (3)of rule 3 inserted vide S.O.23(E), dt.16.01.1991.

The Environment (Protection) Rules, 1986

391

1

[(3A) (i) Notwithstanding anything contained in sub-rules (1) and (2), on and

from the 1st day of January, 1994, emission or discharge of environmental pollutants

from the

2

[industries, operations or processes other than those industries, operations or

processes for which standards have been specified in Schedule-I] shall not exceed the

relevant parameters and standards specified in schedule VI.

Provided that the State Boards may specify more stringent standards for the

relevant parameters with respect to specific industry or locations after recording reasons

therefore in writing.

(ii) The State Board shall while enforcing the standards specified in

Schedule VI follow the guidelines specified in Annexure I and II in that

Schedule.]

3

[(3B)] The combined effect of emission or discharge of environmental

pollutants in an area, from industries, operations, processes, automobiles and domestic

sources, shall not be permitted to exceed the relevant concentration in ambient air as

specified against each pollutant

4

[in columns (4) and (5) of Schedule VII.]

(4) Notwithstanding anything contained in sub-rule (3)-

(a) the Central Board or a State Board, depending on the local conditions

or nature of discharge of environmental pollutants, may, by order, specify a

lesser period than a period specified under sub-rule (3) within which the

compliance of standards shall be made by an industry, operation or process.

(b) the Central Government in respect of any specific industry, operation

or process, by order, may specify any period other than a period specified under

sub-rule (3) within which the compliance of standards shall be made by such

industry, operation or process.

(5) Notwithstanding anything contained in sub-rule (3) the standards for emission

or discharge of environmental pollutants specified under sub-rule (1) or sub-rule (2) in

respect of an industry, operation or process before the commencement of the

Environment (Protection) Amendment Rules, 1991, shall be complied by such industry,

operation or process by the 31

st

day of December 1991.

1

The sub-rule (3A) of rule 3 inserted by rule 2(a)(iii) of the Environment (Protection) Second Amendment Rules, 1993

notified vide GSR 422(E) dt.19.05.1993, published in the Gazette No.174 dated 19.05.1993.

2

Substituted by rule 2(a) of the Environment (Protection) Third Amendment Rules, 1993 notified vide Notification

G.S.R 801(E), dt.31.12.1993, published in Gazette No.463 dt.31.12.1993.

3

Substituted by Rule 2(a) of the Environment (Protection) Second (Amendment) Rules, 1998 notified by notification

GSR 7, dated 22.12.1998.

4

Substituted by Rule 2 of the Environment (Protection) Seventh Amendment Rules, 2009 notified by GSR 826(E),

dated 16.11.2009.

The Environment (Protection) Rules, 1986

392

1

[(6) Notwithstanding anything contained in sub-rule (3), an industry, operation

or process which has commenced production on or before 16

th

May, 1981 and has shown

adequate proof of atleast commencement of physical work for establishment of facilities

to meet the specified standards within a time-bound programme, to the satisfaction of the

concerned State Pollution Control Board, shall comply with such standards latest by the

31

st

day of December, 1993.

(7) Notwithstanding anything contained in sub-rule (3) or sub-rule (6) an

industry, operation or process which has commenced production after the 16

th

day of

May, 1981 but before the 31

st

day of December 1991 and has shown adequate proof of at

least commencement of physical work for establishment of facilities to meet the specified

standards within a time-bound programme, to the satisfaction of the concerned State

Pollution Control Board, shall comply with such standards latest by the 31

st

day of

December, 1992.]

2

[(8) On and from the 1

st

day of

3

[June, 2002], the following coal based thermal

power plants shall use

4

[raw or blended or beneficiated coal with an ash content not

exceeding thirty four per cent on an annual average basis.], namely:-

(a) any thermal power plant located beyond one thousand kilometers from the pit-

head; and

(b) any thermal power plant located in urban area or sensitive area or critically

polluted area irrespective of their distance from pit-head except any pit-head

power plant.

5

[Provided that any thermal power plant using Circulating Fluidised Bed

Combustion or Atmosphere Fluidised Bed Combustion or Pressurized Fluidised Bed

Combustion or integrated Gasification Combined Cycle technologies or any other

clean technologies as may be notified by the Central Government in the Official

Gazette shall be exempted from Clauses (a) and (b)]

Explanation: For the purpose of this Rule :-

(a) „beneficiated coal‟ means coal containing higher calorific value but lower ash

than the original ash content in the raw coal obtained through physical separation

or washing process.

1

Sub-rule (6) and (7) of rule 3 were added by the Environment (Protection) Amendment Rule, 1992 vide G.S.R. 95(E)

dated 12.02.1992.

2

Inserted by Rule 2 of the Environment (Protection) Amendment Rules, 1997 vide G.S.R.560(E), dated 19.9.1997.

3

Substituted vide G.S.R.407(E), dated 31.5.2001.

4

Substituted vide G.S.R.378 (E), dated 30.6.1998.

5

Inserted vide G.S.R. 378 (E), dated 30.6.1998.

The Environment (Protection) Rules, 1986

393

(b) „pit-head power plant‟ means power stations having captive transportation

system for its exclusive use for transportation of coal from the loading point at

the mining end upto the uploading point at the power station without using the

normal public transportation system.;

(c) „sensitive area‟ means an area whose ecological balance is prone to be easily

disturbed.

(d) „critically polluted area‟ means the area where pollution level has reached or

likely to reach to the critical level and which has been identified as such by the

Central Government or Central Pollution Control Board or a State Pollution

Control Board.

1

[(e) „urban area‟ means an area limit of a city having a population of more than 1

million according to 1991 census.]

4. DIRECTIONS

(1) Any direction issued under section 5 shall be in writing.

(2) The direction shall specify the nature of action to be taken and the time within

which it shall be complied with by the person, officer or the authority to whom such

direction is given.

2

[(3) (a) The person, officer or authority to whom any direction is sought to be

issued shall be served with a copy of the proposed direction and shall be given an

opportunity of not less than fifteen days from the date of service of a notice to

file with an officer designated in this behalf the objections, if any, to the issue of

the proposed direction.

(b) Where the proposed direction is for the stoppage or regulation of

electricity or water or any other service affecting the carrying on any industry,

operation or process and is sought to be issued to an officer or an authority, a

copy of the proposed direction shall also be endorsed to the occupier of the

industry, operation or process, as the case may be and objections, if any, filed by

the occupier with an officer designated in this behalf shall be dealt with in

accordance with the procedures under sub-rules (3a) and (4) of this rule:

Provided that no opportunity of being heard shall be given to the

occupier if he had already been heard earlier and the proposed direction

referred to in sub-rule (3b) above for the stoppage or regulation of electricity or

1

Inserted vide G.S.R.378(E), dated 30.6.1998.

2

Sub-rule (3) of rule 4 of the Principal Rules was re-numbered as sub-rule 3(a) and sub-rule 3(b) inserted vide

Notification No. S.O. 64(E) published in the Gazette No. 42 dated 18.1.88.

The Environment (Protection) Rules, 1986

394

water or any other service was the resultant decision of the Central Government

after such earlier hearing

.

]

(4) The Central Government shall within a period of 45 days from the date of

receipt of the objections, if any or from the date up to which an opportunity is given to

the person, officer or authority to file objections whichever is earlier, after considering

the objections, if any, received from the person, officer or authority sought to be directed

and for reasons to be recorded in writing, confirm, modify or decide not to issue the

proposed direction.

(5) In case where the Central Government is of the opinion that in view of the

likelihood of a grave injury to the environment it is not expedient to provide an

opportunity to file objections against the proposed direction, it may, for reasons to be

recorded in writing, issue directions without providing such an opportunity.

(6) Every notice or direction required to be issued under this rule shall be deemed

to be duly served

(a) where the person to be served is a company, if the document is

addressed in the name of the company at its registered office or at its principal

office or place of business and is either-

(i) sent by registered post, or

(ii) delivered at its registered office or at the principal office or

place of business;

(b) where the person to be served is an officer serving Government, if the

document is addressed to the person and a copy thereof is endorsed to this Head

of the Department and also to the Secretary to the Government, as the case may

be, in-charge of the Department in which for the time being the business relating

to the Department in which the officer is employed is transacted and is either-

(i) sent by registered post, or

(ii) is given or tendered to him;

(c) in any other case, if the document is addressed to the person to be

served and-

(i) is given or tendered to him, or

(ii) if such person cannot be found, is affixed on some

conspicuous part of his last known place of residence or business or is

given or tendered to some adult member of his family or is affixed on

some conspicuous part of the land or building, if any, to which it relates, or

The Environment (Protection) Rules, 1986

395

(iii) is sent by registered post to that person;

Explanation.-For the purpose of this sub-rule:-

(a) "company" means any body corporate and includes a firm or other

association of individuals;

(b) "a servant" is not a member of the family.

5. PROHIBITION AND RESTRICTION ON THE LOCATION OF INDUSTRIES

AND THE CARRYING ON PROCESSES AND OPERATIONS IN DIFFERENT

AREAS

(1) The Central government may take into consideration the following factors

while prohibiting or restricting the location of industries and carrying on of processes and

operations in different areas-

(i) Standards for quality of environment in its various aspects laid down

for an area.

(ii) The maximum allowable limits of concentration of various

environmental pollutants (including noise) for an area.

(iii) The likely emission or discharge of environmental pollutants from

an industry, process or operation proposed to be prohibited or restricted.

(iv) The topographic and climatic features of an area.

(v) The biological diversity of the area which, in the opinion of the

Central Government needs to be preserved.

(vi) Environmentally compatible land use.

(vii) Net adverse environmental impact likely to be caused by an

industry, process or operation proposed to be prohibited or restricted.

(viii) Proximity to a protected area under the Ancient Monuments and

Archaeological Sites and Remains Act, 1958 or a sanctuary, National Park, game

reserve or closed area notified as such under the Wild Life (Protection) Act, 1972

or places protected under any treaty, agreement or convention with any other

country or countries or in pursuance of any decision made in any international

conference, association or other body.

(ix) Proximity to human settlements.

The Environment (Protection) Rules, 1986

396

(x) Any other factor as may be considered by the Central Government to

be relevant to the protection of the environment in an area.

(2) While prohibiting or restricting the location of industries and carrying on of

processes and operations in an area, the Central Government shall follow the procedure

hereinafter laid down.

(3) (a) Whenever it appears to the Central Government that it is expedient to

impose prohibition or restrictions on the locations of an industry or the carrying

on of processes and operations in an area, it may by notification in the Official

Gazette and in such other manner as the Central Government may deem

necessary from time to time, give notice of its intention to do so.

(b) Every notification under clause (a) shall give a brief description of

the area, the industries, operations, processes in that area about which such

notification pertains and also specify the reasons for the imposition of prohibition

or restrictions on the locations of the industries and carrying on of process or

operations in that area.

(c) Any person interested in filing an objection against the imposition of

prohibition or restrictions on carrying on of processes or operations as notified

under clause (a) may do so in writing to the Central Government within sixty

days from the date of publication of the notification in the Official Gazette.

(d) The Central Government shall within a period of one hundred and

twenty days from the date of publication of the notification in the Official

Gazette consider all the objections received against such notification and may

within

1

[three hundred and sixty five days] from such day of publication] impose

prohibition or restrictions on location of such industries and the carrying on of

any process or operation in an area.

2

[(4) Notwithstanding anything contained in sub-rule (3), whenever it

appears to the Central Government that it is in public interest to do so, it may

dispense with the requirement of notice under clause (a) of sub-rule (3).]

3

[6. PROCEDURE FOR TAKING SAMPLES

The Central Government or the officer empowered to take samples under section

11 shall collect the sample in sufficient quantity to be divided into two uniform parts and

effectively seal and suitably mark the same and permit to the person from whom the

sample is taken to add his own seal or mark to all or any of the portions so sealed and

marked. In case where the sample is made up in containers or small volumes and is likely

to deteriorate or be otherwise damaged if exposed, the Central Government or the officer

1

Substituted for the words “one hundred and eight days” the words “three hundred and sixty five days” by Rule 2 of

the Environment (Protection) Eighth Amendment Rules, 1992

2

Inserted by Rule 2 of the Environment (Protection) Amendment Rules, 1994 notified by G.S.R.320(E), dated

16.3.1994.

3

For rule 6 of the principal rules this rule was substitute vide S.O. 64(E) published in the Gazette No. 42 dated 18.1.88.

The Environment (Protection) Rules, 1986

397

empowered shall take two of the said samples without opening the containers and

suitably seal and mark the same. The Central Government or the officer empowered shall

dispose of the samples so collected as follows:-

(i) One portion shall be handed over to the person from whom the sample

is taken under acknowledgement; and

(ii) The other portion shall be sent forthwith to the environmental

laboratory or analysts.]

7. SERVICE OF NOTICE

The Central Government or the officer empowered shall serve on the occupier or

his agent or person in charge of the place a notice then and there in Form I of his

intention to have the sample analysed.

8. PROCEDURE FOR SUBMISSION OF SAMPLES FOR ANALYSIS, AND THE

FORM OF LABORATORY REPORT THEREON

(1) Sample taken for analysis shall be sent by the Central Government or the

officer empowered to the environmental laboratory by registered post or through special

messenger along with Form II.

(2) Another copy of Form II together with specimen impression of seals of the

officer empowered to take samples along with the seals/marks, if any, of the person from

whom the sample is taken shall be sent separately in a sealed cover by registered post or

through a special messenger to the environmental laboratory.

(3) The findings shall be recorded in Form III in triplicate and signed by the

Government Analyst and sent to the officer from whom the sample is received for

analysis.

(4) On receipt of the report of the findings of the Government Analyst, the officer

shall send one copy of the report to the person from whom the sample was taken for

analysis, the second copy shall be retained by him for his record and the third copy shall

be kept by him to be produced in the Court before which proceedings, if any, are

instituted.

9. FUNCTIONS OF ENVIRONMENTAL LABORATORIES

The following shall be the functions of environmental laboratories:-

(i) to evolve standardized methods for sampling and analysis of various

types of environmental pollutants;

The Environment (Protection) Rules, 1986

398

(ii) to analyze samples sent by the Central Government or the officers

empowered under sub-section (1) of section 11.

(iii) to carry out such investigations as may be directed by the Central

Government to lay down standards for the quality of environment and discharge

of environmental pollutants, to monitor and to enforce the standards laid down;

(iv) to send periodical reports regarding its activities to the Central

Government;

(v) to carry out such other functions as may be entrusted to it by the

Central Government from time to time.

10. QUALIFICATIONS OF GOVERNMENT ANALYST

A person shall not be qualified for appointment or recognized as a Government Analyst

unless he is a:-

(a) graduate in science from a recognized university with five years

experience in laboratory engaged in environmental investigation, testing or

analysis; or

(b) post-graduate in science or a graduate in engineering or a graduate in

medicine or equivalent with two years experience in a laboratory engaged in

environmental investigations testing or analysis; or

(c) post-graduate in environmental science from a recognized university

with two years experience in a laboratory engaged in environmental

investigations, testing or analysis.

11. MANNER OF GIVING NOTICE

The manner of giving notice under clause (b) of section 19 shall be as follows,

namely:-

(l) The notice shall be in writing in Form IV.

(2) The person giving notice may send notice to-

(a) if the alleged offence has taken place in a Union territory

(A) the Central Board and

(B) Ministry of Environment and Forests (represented by the

Secretary to Government of India);

The Environment (Protection) Rules, 1986

399

(b) if the alleged offence has taken place in a State:

(A) the State Board; and

(B) the Government of the State (represented by the Secretary to

the State Government in-charge of environment); and

(C) the Ministry of Environment and Forests (represented by the

Secretary to the Government of India);

(3) The notice shall be sent by registered post acknowledgement due; and

(4) The period of sixty days mentioned in clause (b) of section 19 of the

Environment (Protection) Act, 1986 shall be reckoned from the date it is first received by

one of the authorities mentioned above.

1

[12. FURNISHING OF INFORMATION TO AUTHORITIES AND AGENCIES

IN CERTAIN CASES

Where the discharge of environmental pollutant in excess of the prescribed

standards occurs or is apprehended to occur due to any accident or other unforeseen act

or event, the person in charge of the place at which such discharge occurs or is

apprehended to occur shall forth with intimate the fact of such occurrence or

apprehension of such occurrence to all the following authorities or agencies, namely:-

(i) The officer-in-charge of emergency or disaster relief operation in a

district or other region of a state or Union territory specified by whatever

designation by the Government of the said State or Union territory, and in whose

jurisdiction the industry, process or operation is located.

(ii) Central Board or a State Board as the case may be and its regional

officer having local jurisdiction who have been delegated powers under section

20, 21, 23 of the Water (Prevention and Control of Pollution) Act, 1974 (6 of

l974) and section 24 of the Air (Prevention and Control of Pollution) Act, 1981

(14 of 1981).

(iii) The statutory authorities or agencies specified in column 3 in

relation to places mentioned in column 2 against thereof of the Schedule II.]

1

Rule 12 inserted vide Notification No. S.O. 32(E) dated 16.2.87 published in the Gazette No. 66 dated 16.2.87.

The Environment (Protection) Rules, 1986

400

1

[13. PROHIBITION AND RESTRICTION ON THE HANDLING OF

HAZARDOUS SUBSTANCES IN DIFFERENT AREAS

(1) The Central Government may take into consideration the following factors

while prohibiting or restricting the handling of hazardous substances in different areas-

(i) The hazardous nature of the substance (either in qualitative or

quantitative terms as far as may be) in terms of its damage causing potential to

the environment, human beings, other living creatures, plants and property;

(ii) the substances that may be or likely to be readily available as

substitutes for the substances proposed to be prohibited or restricted;

(iii) the indigenous availability of the substitute, or the state of

technology available in the country for developing a safe substitute;

(iv) the gestation period that may be necessary for gradual introduction

of a new substitute with a view to bringing about a total prohibition of the

hazardous substance in question; and

(v) any other factor as may be considered by the Central Government to

be relevant to the protection of environment.

(2) While prohibiting or restricting the handling of hazardous substances in an

area including their imports and exports the Central Government shall follow the

procedure hereinafter laid down-

(i) Whenever it appears to the Central Government that it is expedient to

impose prohibition or restriction on the handling of hazardous substances in an

area, it may, by notification in the Official Gazette and in such other manner as

the Central Government may deem necessary from time to time, give notice of its

intention to do so.

(ii) Every notification under clause (i) shall give a brief description of the

hazardous substances and the geographical region or the area to which such

notification pertains, and also specify the reasons for the imposition of

prohibition or restriction on the handling of such hazardous substances in that

region or area.

(iii) Any person interested in filing an objection against the imposition of

prohibition or restrictions on the handling of hazardous substances as notified

under clause (i) may do so in writing to the Central Government within sixty

days from the date of publication of the notification in the Official Gazette.

1

Rule 13 inserted vide Notification No G.S.R. 931(E) dated 27.10.89 published in the Gazette No. 564 dated 27.10.89.

The Environment (Protection) Rules, 1986

401

(iv) The Central Government shall within a period of ninety days

from the date of publication of the notification in the official Gazette consider

all the objections received against such notification and may impose

prohibition or restrictions on the handling of hazardous substances in a region

or an area.]

1

[14. SUBMISSION OF ENVIRONMENTAL

2

[STATEMENT]

Every person carrying on an industry, operation or process requiring consent

under Section 25 of the Water (Prevention and Control of Pollution) Act, 1974 (6 of

1974) or under section 21 of the Air (Prevention and Control of Pollution) Act, 1981

(14 of 1981) or both or authorization under the Hazardous Wastes (Management and

Handling) Rules, 1989 issued under the Environment (Protection) Act, 1986 (29 of

1986) shall submit an environmental

2

[statement] for the financial year ending the 31

st

March in Form V to the concerned State Pollution Control Board on or before the

3

[thirtieth day of September] every year, beginning 1993.]

1

Inserted by Rule 2 of the Environment (Protection) (second amendment) Rules, 1992 vide notification G.S.R. 329(E),

dated 13.3.1992.

2

Substituted by Rule 2(a) (i) of the Environment (Protection) Amendment Rules, 1993 vide notification G.S.R.

386(E), dated 22.4.1993

3

Substituted by Rule 2(a) (ii), ibid

The Environment (Protection) Rules, 1986

402

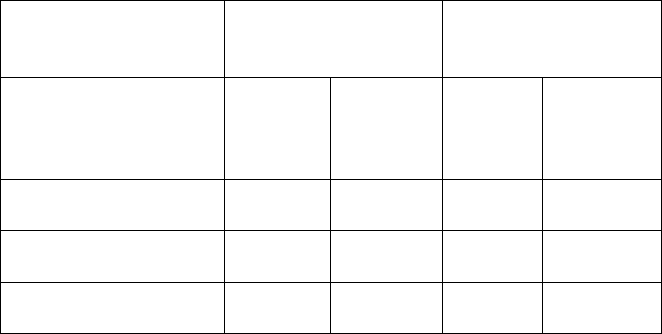

STANDARDS FOR EMISSION OR DISCHARGE OF

ENVIRONMENTAL POLLUTANTS

1

SCHEDULE – I (See rule 3)

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

1.

CAUSTIC SODA

INDUSTRY

Concentration not to exceed,

miligramme per lit. (except for pH

and flow)

Total concentration of

mercury in the final effluent

*

0.01

Mercury bearing waste-water

generation (flow)

10 kilolitres/ tonne of caustic soda

produced.

pH

5.5 to 9.0

*Final effluent is the combined effluent from (a) cell house, (b) brine

plant, (c) chlorine handling (d) hydrogen handling (e) hydrochloric

acid plant.

**2.

MAN-MADE

FIBRES

(SYNTHETIC)

Concentration not to exceed

miligramme per litre (except for pH)

Suspended solids

100

Bio-chemical oxygen demand

2

[BOD 3 days at 27

o

C]

30

pH

5.5 to 9.0

3

[3.

PETROLEUM

OIL REFINERY

A. EFFLUENT

1. pH

6.0-8.5

2. Oil & Grease

5.0

3. BOD

3 days, 27

o

C

15.0

4. COD

125.0

5. Suspended Solids

20.0

6. Phenols

0.35

7. Sulphides

0.5

8. CN

0.20

9. Ammonia as N

15.0

10. TKN

40.0

11. P

3.0

1

The Environment (Protection) Rules, 1986 are referred to as principal rules in all subsequent Notifications

beginning with S.O. 32(E), dated 16.2.1987 published in the Gazette no. 66, dated 16.2.1987. The Schedule to be

principal rules was renumbered as Schedule-I vide S.O. 32(E) supra.

**

Standards notified at Sl. No. 60 may also be referred.

2

Substituted by Rule 2 of the Environment (Protection) Amendment Rules, 1996 notified by G.S.R.176(E), dated

2.4.1996 may be read as BOD (3 days at 27

o

C) wherever BOD 5 days 20

o

C occurred.

3

Substituted by Rule 2 (i) of the Environment (Protection) Amendment Rules, 2008 notified by G.S.R.186(E),

dated 18.3.2008.

The Environment (Protection) Rules, 1986

403

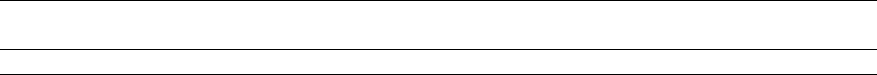

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

12. Cr (Hexavalent)

0.1

13. Cr (Total)

2.0

14. Pb

0.1

15. Hg

0.01

16. Zn

5.0

17. Ni

1.0

18. Cu

1.0

19. V

0.2

20. Benzene

0.1

21. Benzo (a) – Pyrene

0.2

Notes:-

(i) Concentration limits shall be complied with at the outlet, discharging effluent

(excluding discharge from sea water cooling systems) to receiving

environment (surface water Bodies, marine systems or public sewers). In

case of application of treated effluent directly for irrigation/horticulture

purposes (within or outside the premises of refinery), make-up water for

cooling systems, fire fighting, etc., the concentration limits shall also be

complied with at the outlet before taking the effluent for such application.

However, any use in the process such as use of sour water in desalter is

excluded for the purpose of compliance.

(ii) In case of circulating seawater cooling, the blow-down from cooling systems

shall be monitored for pH and oil & grease (also hexavalent & total

chromium, if chromate treatment is given to cooling water) and shall

conform to the concentration limits for these parameters. In case of reuse of

treated effluent as cooling water make-up, all the parameters (as applicable

for treated effluent) shall be monitored and conform to the prescribed

standards.

(iii) In case of once through cooling with seawater, the oil & grease content in the

effluent from cooling water shall not exceed 1.0 mg/l.

B. EMISSIONS

Limiting concentration in mg/Nm

3

, unless stated

(Furnace, Boiler

and Captive

Power Plant)

Fuel

Type

Existing

refineries

New Refinery/

Furnace/

Boiler

Sulphur Dioxide

(SO

2

)

Gas

50

50

Liquid

1700

850

Oxides of Nitrogen

(NOx)

Gas

350

250

Liquid

450

350

Particulate Matter

(PM)

Gas

10

5

Liquid

100

50

The Environment (Protection) Rules, 1986

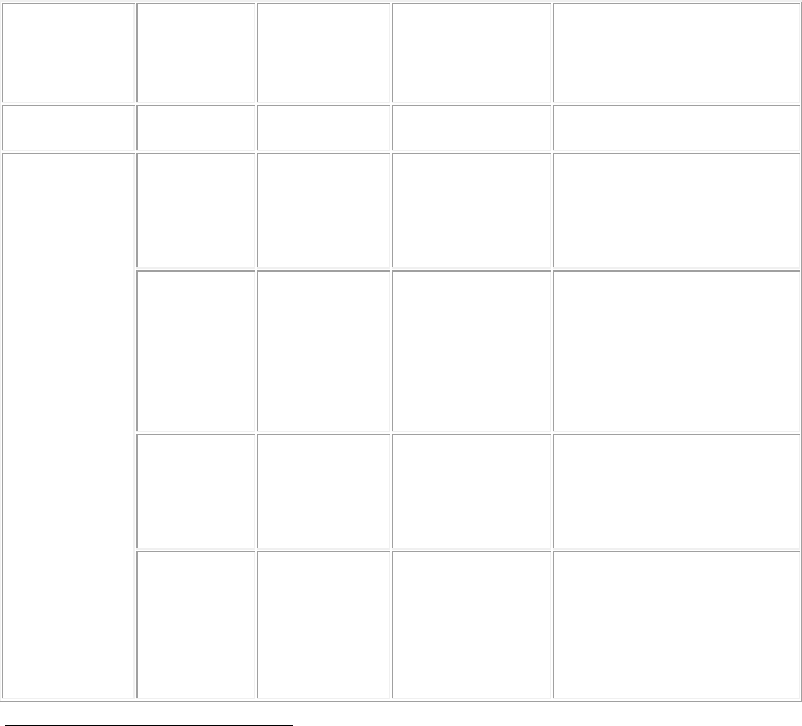

404

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Carbon Monoxide

(CO)

Gas

150

100

Liquid

200

150

Nickel and Vanadium

(Ni+v)

Liquid

5

5

Hydrogen Sulphide

(H

2

S) in fuel gas

Liquid /

Gas

150

150

Sulphur content in

liquid fuel, weight%

Liquid /

Gas

1.0

0.5

Notes:-

(i) In case of mixed fuel (gas and liquid) use, the limit shall be computed based on

heat supplied by gas and liquid fuels.

(ii) All the furnaces/boilers with heat input of 10 million kilo calories/hour or more

shall have continuous systems for monitoring of SO

2

and NO

2.

Manual

monitoring for all the emission parameters in such furnaces or boilers shall be

carried out once in two months.

(iii) All the emission parameters in furnaces/boilers having heat input less than 10

million kilo calories/hour will be monitored once in three months.

(iv) In case of continuous monitoring, one hourly average concentration values shall

be complied with 98% of the time in a month. Any concentration value obtained

through manual monitoring, if exceeds the limiting concentration value, shall be

considered as non-compliance.

(v) Data on Nickel and Vanadium content in the liquid fuel (in ppm) shall be

reported. Nickel and Vanadium in the liquid fuel shall be monitored at least once

in six months, if liquid fuel source & quality are not changed. In case of

changes, measurement is necessary after every change.

(FCC

Regenerators)

Limiting concentration in mg/Nm

3

,

unless stated

Existing refineries

New Refinery

/FCC

Commissioned

Hydro

processed

FCC feed

Other than

Hydro

processed

FCC feed

Sulphur Dioxide

(SO

2

)

500

1700

500 (for hydro-

processed feed)

850 for other

feed)

Oxides of Nitrogen

(NO

x

)

400

450

350

Particulate Matter

(PM)

100

100

50

Carbon Monoxide

(CO)

400

400

300

Nickel and

Vanadium (Ni+V)

2

5

2

Opacity, %

30

30

30

The Environment (Protection) Rules, 1986

405

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Notes:-

(i) In case part feed is hydro-processed, the emission values shall be calculated

proportional to the feed rates of untreated and treated feeds.

(ii) FCC regenerators shall have continuous systems for monitoring of SO

2

and

NO

x.

One hourly average concentration values shall be complied with 98% of

the time in a month, in case of continuous monitoring. Manual monitoring

for all the emission parameters shall be carried out once in two months.

(iii) Any concentration value obtained through manual monitoring, if exceeds the

limiting concentration value, shall be considered as non-compliance.

(iv) Data on Sulphur (weight in %), Nickel (PPM) and Vanadium (PPM) content

in the feed to FCC shall be separated regularly.

(v) Limit of Carbon Monoxide emissions shall be complied with except during

annual shut down of CO boiler for statutory maintenance.

Plant

Capacity

(Tonnes/day)

Existing

SRU

New SRU or

Refinery

Commissioned

{Sulphur,

Recovery

Units (SRU)}

Sulphur recovery, %

Above 20

98.7

99.5

H

2

S, mg/Nm

3

15

10

Sulphur recovery, %

5-20

96

98

Sulphur recovery, %

1-5

94

96

Oxides of Nitrogen

(NO

x

), mg/Nm

3

All capacity

350

250

Carbon Monoxide

(CO), mg/Nm

3

All capacity

150

100

Notes:-

(i) Sulphur recovery units having capacity above 20 tonnes per day shall have

continuous systems for monitoring of SO

2.

Manual monitoring for all the

emission parameters shall be carried out once in a month.

(ii) Data on Sulphur Dioxide emissions (mg/Nm

3

) shall be reported regularly.

(iii) Sulphur recovery efficiency shall be calculated on monthly basis, using

quantity of sulphur in the feed to SRU and quantity of sulphur recovered.

The Environment (Protection) Rules, 1986

406

C- FUGITIVE EMISSION

Storage of Volatile Liquids : General Petroleum Products

(1) Storage tanks with capacity between 4 to 75m

3

and total vapour Pressure

(TVP) of more than 10 kpa should have Fixed Roof Tank (FRT) with

pressure valve vent.

(2) Storage tank with the capacity between 75 to 500 m

3

and total vapour

Pressure (TVP) of 10 to 76 kpa should have Internal Floating Root Tank

(IFRT) of External Floating Root Tank (EFRT) or Fixed Roof Tank with

vapour control or vapour balancing system.

(3) Storage tanks with the capacity of more than 500 m

3

and total vapour

Pressure (TVP) of 10 to 76 kpa should have Internal Floating Roof Tank or

External Floating Roof Tank or Fixed Roof Tank with vapour control system.

(4) The tanks with the capacity of more than 75 m

3

and total vapour Pressure

(TVP) of more than 76 kpa should have Fixed Root Tank with vapour control

system.

(5) Requirement for seals in Floating Roof Tanks:

(i) (a) IFRT and EFRT shall be provided with double seals with

minimum vapour recovery of 96%.

(b) Primary seal shall be liquid or shoe mounted for EFRT and

vapour mounted for IFRT. Maximum seal gap width will be

4 cm and maximum gap area will be 200 cm

2

/m of tank

diameter.

(c) Secondary seal shall be rim mounted. Maximum seal gap

width will be 1.3 cm and maximum gap area will be 20

cm

2

/m of tank diameter.

(d) Material of seal and construction shall ensure high

performance and durability.

(ii) Fixed Roof Tanks shall have vapour control efficiency of 95%

and vapour balancing efficiency of 90%

(iii) Inspection and maintenance of storage tanks shall be carried out

under strict control. For the inspection, API RP 575 may be

adopted, In-service inspection with regard seal gap should be

carried out once in every six months and repair to be

implemented in short time. In future, possibility of on-stream

repair of both seals shall be examined.

The Environment (Protection) Rules, 1986

407

Storage of Volatile Liquids : Benzene Storage

(1) FRT with vapour to incineration with 99.9% of removal efficiency for

volatile organic compounds (VOC) shall be provided.

(2) IFRT/EFRT with double seals, emission-reducing roof fitting and fitted with

fixed roof with vapour removal efficiency of at least 99% shall be provided.

Solvents for Lube-Base Oil production (Furfural, NMP, MEK, Toluene and

MIBK)

IFRT with double seals and inert gas blanketing with vapour removal efficiency of at

least 97% shall be provided.

Emission control for Road tank truck/Rail tank wagon loading

Loading of Volatile

Products

Gasoline and Naphtha:

(i) VOC reduction, %.

(ii) Emission, gm/m

3

(i) 99.5

(ii) 5

Benzene:

(i) VOC reduction, %

(ii) Emission, mg/m

3

(i) 99.99

(ii) 20

Toluene/Xylene:

(i) VOC reduction, %

(ii) Emission, mg/m

3

(i) 99.98

(ii) 150

Note:

(i) It shall be applicable for Gasoline, Naphtha,

Benzene, Toluene and Xylene loading.

(ii) Road tank Truck shall have Bottom loading and

Roll tank wagon shall have Top submerged

loading.

(iii) Annual leak testing for vapour collection shall be

done.

Standards for Equipment Leaks

(1) Approach: Approach for controlling fugitive emissions from

equipment leaks shall have proper selection, installation and

maintenance of non-leaking or leak-tight equipment. Following

initial testing after commissioning, the monitoring for leak detection

is to be carried out as a permanent on-going Leak Detection and

Repair (LDAR) programme. Finally detected leaks are to be repaired

within allowable time frame.

The Environment (Protection) Rules, 1986

408

(2) Components to be Covered: Components that shall be covered under

LDAR programme include (i) Block valves; (ii) Control valves;

(iii) Pump seals; (iv) Compressor seals; (v) Pressure relief valves;

(vi) Flanges – Heat Exchangers; (vii) Flanges – Piping; (viii)

Connectors – Piping; (ix) Open ended lines; and (x) Sampling

connections, Equipment and line sizes more than 1.875 cm or ¾ inch

are to be covered.

(3) Applicability: LDAR programme would be applicable to components

(given at 2 above) for following products/compounds: (i)

hydrocarbon gases; (ii) Light liquid with vapour pressure @ 20

o

C

> 1.0 kPa; and (iii) Heavy liquid with vapour pressure @ 20

o

C

between 0.3 to 1.0 kPa.

(4) While LDAR will not be applicable for heavy liquids with vapour

pressure < 0.3 kPa, it will be desirable to check for liquid dripping as

indication of leak.

(5) Definition of leak: A leak is defined as the detection of VOC

concentration more than the values (in ppm) specified below at the

emission source using a hydrocarbon analyzer according to

measurement protocol (US EPA – 453/R-95-017, 1995 Protocol for

equipment leak emission estimates may be referred to:

Component

General

Hydrocarbon (ppm)

Benzene (ppm)

Till 31

st

Dec.

2008

w.e.f.

January

01, 2009

Till 31

st

Dec.,

2008

w.e.f

January

01, 2009

Pump/Compressor

10000

5000

3000

2000

Valves/Flanges

10000

3000

2000

1000

Other components

10000

3000

2000

1000

(6) In addition, any component observe to be leaking by sight, sound or

smell, regardless of concentration (liquid dripping, visible vapor

leak) or presence of bubbles using soap solution should be

considered as leak.

(7) Monitoring Requirements and Repair Schedule: Following frequency

of monitoring of leaks and schedule for repair of leaks shall be

followed:

The Environment (Protection) Rules, 1986

409

Component

Frequency of

monitoring

Repair schedule

Quarterly (semiannual

after two consecutive

periods with < 2%

leaks and annual after

5 periods with < 2%

leaks)

Repair will be started

within 5 working days

and shall be completed

within 15 working days

after detection of leak for

general hydrocarbons. In

case of benzene, the leak

shall be attended

immediately for repair.

Pump seals

Quarterly

Compressor seals

Quarterly

Pressure relief

devices

Quarterly

Pressure relief

devices (after

venting)

Within 24 hours

Heat Exchangers

Quarterly

Process drains

Annually

Components that

are difficult to

monitor

Annually

Pump seals with

visible liquid

dripping

Immediately

Immediately

Any component

with visible leaks

Immediately

Immediately

Any component

after repair/

replacement

Within five days

-

(8) The percentage leaking components should not be more than 2% for any

group of components monitored excluding pumps/compressors. In case of

pumps/compressors it should be less than 10% of the total number of

pumps/compressors or three pumps and compressors, whichever is greater.

(9) Emission inventory: Refinery shall prepare on inventory of equipment

components in the plant. After the instrumental measurement of leaks,

emission from the components will be calculated using stratified emission

factor (USEPA) or any other superior factors. The total fugitive emission

will be established.

The Environment (Protection) Rules, 1986

410

(10) Monitoring following types of monitoring methods may be judiciously

employed for detection of leaks: (i) instrumental method of measurement of

leaks; (ii) Audio, visual and olfactory (AVO) leak detection; and (iii) Soap

bubble method.

(11) Data on time of measurement and concentration value for leak detection;

time of repair of leak; and time of measurement & concentration value after

repair of leak should be documented for all the components.

(12) Pressure relief and blow down systems should discharge to a vapour

collection and recovery system or to flare.

(13) Open-ended lines should be closed by a blind flange or plugged.

(14) Totally closed-loop should be used in all routine samples.

(15) Low emission packing should be used for valves.

(16) High integrity sealing materials should be used for flanges.

D. Emission Standards for VOC from Wastewater Collection and Treatment

(1) All contaminated and odorous wastewater streams shall be handled in closed

systems from the source to the primary treatment stages (oil-water separator

and equalization tanks).

(2) The collection system shall be covered with water seals (traps) on sewers and

drains and gas tight covers on junction boxes.

(3) Oil-water separators and equalization tanks shall be provided with

floating/fixed covers. The off-gas generated shall be treated to remove at least

90% of VOC and eliminate odour. The system design shall ensure safety

(prevention of formation of explosive mixture, possible detonation and

reduce the impact) by dilution with air/inert gas, installing LEL detector

including control devices, seal drums, detonation arrestors etc. The system

shall be designed and operated for safe maintenance of the collection and

primary treatment systems.

(4) Wastewater from aromatics plants (benzene and xylene plants) shall be

treated to remove benzene & total aromatics to a level of 10, 20 ppm

respectively before discharge to effluent treatment system without dilution].

The Environment (Protection) Rules, 1986

411

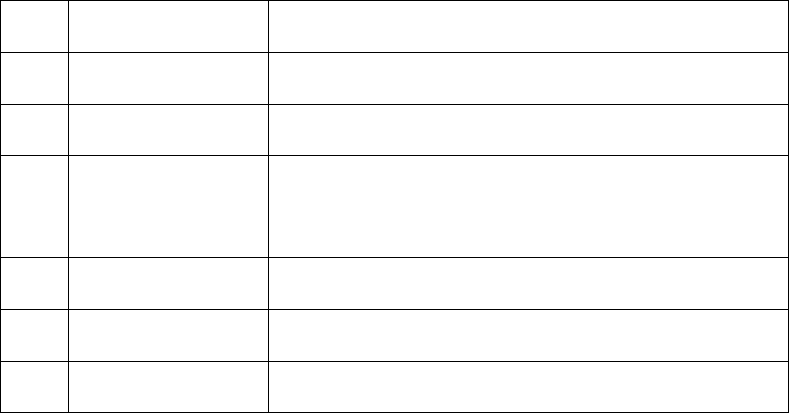

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

4.

SUGAR

INDUSTRY

Concentration not exceed,

milligramme per litre

Bio-chemical oxygen demand,

1

[3 days at 27

o

C]

100 for disposal on land

30 for disposal in surface water

Suspended solids

100 for disposal on land.

30 for disposal in surface waters.

5.

THERMAL

POWER

PLANTS

Maximum limiting concentration,

milligrammes per litre (except for pH

and temperature)

Condenser Cooling

waters (once through

cooling system)

pH

6.5 – 8.5

Temperature

Not more than 5

o

C higher than the

intake water temperature

Free available chlorine

0.5

Boiler blowdowns

Suspended solids

100

Oil and Grease

20

Copper (total)

1.0

Iron (total)

1.0

Cooling tower blowdown

Free available chlorine

0.5

Zinc

1.0

Chromium (total)

0.2

Phosphtate

5.0

Other corrosion

inhibiting material

Limit to be established on case by case

basis by Central Board in case of

Union territories and State Board in

case of States.

Ash pond effluent

pH

6.5 – 8.5

Suspended solids

100

Oil and Grease

20

1

Substituted by Rule 2 of the Environment (Protection) Amendment Rules, 1996 notified by G.S.R.176(E), dated

2.4.1996 may be read as BOD (3 days at 27

o

C) wherever BOD 5 days 20

o

C occurred.

The Environment (Protection) Rules, 1986

412

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

6.

COTTON TEXTILE

INDUSTRIES

(COMPOSITE AND

PROCESSING)

Concentration not to exceed,

milligramme per litre (except for pH

and bioassay)

Common

pH

5.5 to 9

Suspended solids

100

Bio-Chemical Oxygen

Demand

1

[3days at

27

o

C]

150

Oil and grease

10

Bio-assay test

90% survival of fish of after 96 hours

Special:

Total chromium as

(Cr)

2

Sulphide (as S)

2

Phenolic compounds

(as C

4

H

2

OH)

5

The special parameters are to be stipulated by the Central Board in case of Union territories

and State Boards in case of States depending upon the dye used in the industry. Where the

industry uses chrome dyes, sulphur dyes and/or phenolic compounds in the dyeing/printing

process, the limits on chromium of 2 mg/litre, sulphides of 2 mg/litre and phenolic

compounds of 5 mg/litre respectively shall be imposed.

Where the quality requirement of the recipient system so warrants, the limit of BOD should

be lowered upto 30 according to the requirement by the State Boards for the States and the

Central Board for the union territories.

A limit on sodium absorption ratio of 26 should be imposed by the State Boards for the

States and the Central Board for the Union territories if the disposal of effluent is to be made

on land.

1

Substituted by Rule 2 of the Environment (Protection) Amendment Rules, 1996 notified by G.S.R.176(E), dated

2.4.1996 may be read as BOD (3 days at 27

o

C) wherever BOD 5 days 20

o

C occurred.

The Environment (Protection) Rules, 1986

413

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

7.

COMPOSITE

WOOLLEN MILLS

Concentration not be exceed,

milligramme per litre (except for pH

and bioassay)

Common :

Suspended Solids

100

pH

5.5 to 9.0

Bio-chemical oxygen

demand

1

[3days at

27

o

C]

100

Oil and grease

10

Bio-assay

90% survival of fish after 96 hrs.

Special :

Total chromium (as

Cr)

2

Sulphide (as S)

2

Phenolic Compounds

(as C

6

H

5

OH)

5

The special parameters are to be stipulated by the Central Board in case of Union territories

and State Boards in case of State depending upon the dye used in the industry. Where the

industry uses chrome dyes, sulphur dyes and or/phenolic compounds in the dyeing/printing

process, the limits on chromium of 2 mg/litre, sulphides of 2 mg./litre and phenolic

compounds of 5 mg/litre respectively shall be imposed.

Where the quality requirement of the recipient system so warrants, the limit of BOD should

be lowered upto 30 according to the requirement by the State Boards for the States and the

Central Board for the Union territories.

A limit on sodium absorption ratio of 26 should be imposed by the State Boards for the

States and the Central Board for the Union Territories if the disposal of the effluent is to be

made on land.

#1

8

DYE AND DYE

INTERMEDIATE

INDUSTRY

Concentration not to exceed

milligrammes per litre (except for pH,

temperature and bio-assay)

Suspended Solids

100

pH

6 to 8.5

Temperature

Shall not exceed 5

o

C above the

ambient temperature of the receiving

body.

#

Standards notified at Sl. No. 45 may also be referred.

1

Sl. No. 8,9 and 10 and entries relating thereto inserted vide S.O. 393(E) dt. 16.4.87 published in the Gazette No.

185 dt. 16.4.87.

The Environment (Protection) Rules, 1986

414

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Mercury (as Hg)

0.01

Hexavalent (as Cr)

0.1

Chromium (Total

Chromium (as Cr)

2.0

Copper (as Cu)

3.0

Zinc (as Zn)

5.0

Nickel (as Ni)

3.0

Cadmium (as Cd)

2.0

Chloride (as Cl)

1000

Sulphate (as SO

4

)

1000

Phenolic Compounds

(as C

6

H

5

OH)

1.0

Oil and Grease

10

Bio-assay Test (with

1:8 dilution of

effluents)

90% survival of Test animals after 96

hours.

The standards for chlorides and sulphates are applicable or discharge into inland and

surface water courses. However, when discharged on land for irrigation, the limit for

chloride shall not be more than 600 milligrammes per litre and the sodium absorption ratio

shall not exceed 26.

9.

ELECTROPLATING

INDUSTRIES

Concentration not to exceed

milligrammes per litre (except for pH

and temperature)

pH

0.6 to 9.0

Temperature

Shall not exceed 5

o

C above the

ambient temperature of the receiving

body.

Oil and Grease

10

Suspended Solids

100

Cynides (as CN)

0.2

Ammonical

50

Nitrogen (as N)

Total Residual

Chlorides (as Cl)

1.0

The Environment (Protection) Rules, 1986

415

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Cadmium (as Cd)

2.0

Nickei (as Ni)

3.0

Zinc (as Zn)

5.0

Hexavalent

0.1

Chromium as (Cr)

Total Chromium (as

Cr)

2.0

Copper (as Cu)

3.0

Lead (as Pb)

0.1

Iron (as Fe)

3.0

Total Metal

10.0

1

[10.

CEMENT PLANTS

not to exceed mg/Nm

3

A. TOTAL DUST

Plant Capacity

(i)200 tonnes/day

(all sections)

400

(ii) Greater than 200

tonnes/day

(all sections)

250

B. EMISSIONS

(i) For Cement Plants, including Grinding Units, located in critically polluted* or

urban areas with a population of one lakh and above (including 5 Km distance

outside urban boundary):

Particulate Matter

100mg/Nm

3

(ii) New Cement Kilns, including Grinding Units to be installed after the date of

notification:

Particulate Matter

50 mg/Nm

3

* As per the guidelines of the Central Pollution Control Board]

1

Substituted by Rule 2(I) of the Environment (Protection) First Amendment Rules, 2006 notified by G.S.R.46(E),

dated 3.2.2006.

The Environment (Protection) Rules, 1986

416

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

#1

11.

STONE CRUSHING

UNIT

Suspended Particulate

Matter

The suspended particulate matter

measured between 3 metres and 10

metres from any process equipment of

a stone crushing unit shall not exceed

600 microgrammes per cubic metre.

2

12.

COKE OVENS

Concentration in the effluents when

discharged into inland surface waters

not be exceed milligramme per litre

(except for pH)

pH

5.5 – 9.0

Biochemical Oxygen

Demand (27

o

C for 3

days)

30

Suspended Solids

100

Phenolic Compounds

(as C

6

H

5

OH)

5

Cynides (as CN)

0.2

Oil & Grease

10

Ammonical Nitrogen

(as N)

50

13.

SYNTHETIC

RUBBER

Concentration in the effluents when

discharged into inland surface waters

not be exceed milligramme per litre

(except for colour and pH)

Colour

Absent

pH

5.5 – 9.0

Biochemical Oxygen

Demand

1

[BOD (3

days at 27

o

C]

50

Chemical Oxygen

Demand

250

Oil and grease

10.0

1

S.No.11 and entries relating thereto inserted vide SO 443(E)dt.18.4.87 published in the Gazette no. 206 dt. 18.4.87.

#

Standards notified at Sl. No. 37 may also be referred.

2

S.Nos. 12 to 24 and entries relating thereto inserted vide S.O. 64(E) published in the Gazette No. 42 dt. 18.1.88.

The Environment (Protection) Rules, 1986

417

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

14.

SMALL PULP AND

PAPER INDUSTRY

Concentration not be exceed mg/l

(except for pH and sodium absorption

ratio)

*Discharge into inland

surface water

pH

5.5 – 9.0

Suspended Solids

100

BOD

30

Disposal on land

pH

5.5 – 9.0

Suspended Solids

100

BOD

100

Sodium Absorption

Ratio

1

[Absorbable Organic

Halogens

(AOX) in effluent

discharge

26

3.00 kg/ton of paper produced with

effect from the date of publication of

this notification.

2.00 kg/ton of paper produced with

effect from the 1

st

day of March,

2006.

Explanation.- These standards shall apply to all small scale Pulp and Paper Mills having

capacity below 24,000 MT per annum]

2

15.

FERMENTATION

INDUSTRY

(DISTILLERIES,

MALTRIES AND

BREWERIES)

Concentration in the effluents not to

exceed milligramme per litre (except

for pH and colour & odour)

pH

5.5 – 9.0

Colour & Odour

All efforts should be made to remove

colour and unpleasant odour as far as

practicable.

Suspended Solids

100

3

[BOD (3 days at

27

o

C)]

4

[-disposal into inland

surface waters or river/

streams]

30

- disposal on land or

for irrigation]

**[(2)….(7)]

100

1

Inserted by Rule 2 (i) of the Environment (Protection) Third Amendments Rules, 2005 notified vide Notification

G.S.R.546(E), dated 30.8.2005.

2

Entries relating to S.No. 15 corrected in terms of SO 12(E), dt. 8.1.90 published in the Gazette no. 10 dt. 8.1.90.

3

Substituted by Rule 2 of the Environment (Protection) Amendment Rules, 1996 notified by G.S.R.176(E), dated

2.4.1996 may be read as BOD (3 days at 27

o

C) wherever BOD 5 days 20

o

C occurred.

4

Substituted vide Rule 3(a) of the Environment (Protection) (Amendments) Rules, 1996 notified vide

G.S.R.186(E), dated 2.4.1996

The Environment (Protection) Rules, 1986

418

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Note :

1

[(1)] *Wastewater generation shall not exceed 250 metre cube per tonne of

paper produced.

2

[(2)…….(7)]

16.

LEATHER

TANNERIES

Concentration in the effluent not to

exceed milligramme per litre (except

for pH and per cent sodium)

Inland

Surface

Waters

Public

Sewers

Land for

Irrigation

Marine Coastal

areas

(a)

(b)

(c)

(d)

Suspended Solids

100

00

200

100

3

[BOD 3 days at 27

o

C]

30

350

100

100

pH

6.0 – 9.0

6.0 – 9.0

6.0 – 9.0

6.0 – 9.0

Chlorides (as Cl)

1000

1000

200

-

Hexavalent Chromium

(Cr+6)

0.1

0.2

0.1

1.0

Total

2.0

2.0

2.0

2.0

Chromium (as Cr)

Sulphides (as S)

2.0

5.0

-

5.0

Sodium percent

-

60

60

-

Boron (as B)

2.0

2.0

2.0

-

Oil & Grease

10

20

10

20

1

Renumbered as (1) by Notification No.S.O.12(E), dated 8.1.1990

2

Notes 2 to 7 inserted by Notification S.O.12(E), dated 8.1.1990 and omitted by G.S.R.176(E), dated 2.4.1996

w.e.f. 3.4.1996

3

Substituted by Rule 2 of the Environment (Protection) Amendment Rules, 1996 notified by G.S.R.176(E), dated

2.4.1996 may be read as BOD (3 days at 27

o

C) wherever BOD 5 days 20

o

C occurred.

The Environment (Protection) Rules, 1986

419

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

17.

FERTILIZER

INDUSTRY

Concentration in the effluent not to

exceed milligramme per litre (except

for pH )

EFFLUENTS

Plants

Commissioned

January 1, 1982

onwards

Plants

Commissioned

Prior to

January 1,

1982

- Straight

Nitrogeneous

Fertilizers, Excluding

the Calcium

Ammonium Nitrate

and Ammonium

Nitrate Fertilizers

(a)

(b)

pH

6.5 – 8.0

6.5 – 8.0

Ammonical Nitrogen

50

75

Total Kjeldahl

Nitrogen

100

150

Free Ammonical

Nitrogen

4

4

Nitrate Nitrogen

10

10

Cynide as CN

0.2

0.2

Vanadium as V

0.2

0.2

Arsenic as As

0.2

0.2

Suspended solids

100

100

Oil and Grease

10

10

*

Hexavalent

Chromium as Cr.

0.1

0.1

*Total Chromium as

Cr.

2.0

2.0

Straight Nitrogenous

Fertilizers, including

Calcium Ammonium

Nitrate and

Ammonium Nitrate

Fertilizers

Plants

Commissioned

January 1, 1982

onwards

Plants

Commissioned

prior to

January 1,

1982

*

To be complied with at the outlet of Chromate removal unit.

The Environment (Protection) Rules, 1986

420

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

(a)

(b)

pH

6.5 – 8.0

6.5 – 8.0

Ammonical Nitrogen

50

75

Total Kjeidahl

Nitrogen

150

Free Ammonical

Nitrogen

4

4

Nitrate Nitrogen

20

20

Cynide as CN

0.2

0.2

Vanadium as V

0.2

0.2

Arsenic as As

0.2

0.2

Suspended solids

100

100

Oil and Grease

10

10

Hexavalent

Chromium as Cr

0.1

0.1

*Total Chromium as

Cr

2.0

2.0

Complex Fertilizers

excluding Calcium

Ammonium Nitrate,

Ammonium Nitrate &

Ammonium

Nitrophosphate

Feritilizers

Plants

Commissioned

January 1, 1982

onwards

Plants

Commissioned

prior to

January 1,

1982

(a)

(b)

pH

6.5 – 8.0

6.5 – 8.0

Ammonical Nitrogen

50

75

Free Ammonical

Nitrogen

4

4

Total Kjeldahl

Nitrogen

100

100

Nitrate Nitrogen

10

10

To be complied with at the outlet of Chromate removal unit.

The Environment (Protection) Rules, 1986

421

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Cynide as CN

0.2

0.2

Vanadium as V

0.2

0.2

Arsenic as As

0.2

0.2

Phsophate as P

5

5

Suspended solids

100

100

Oil and Grease

10

10

*

Fluoride as F

10

10

**

Hexavalent

Chromium as Cr

0.1

0.1

**Total Chromium as

Cr

2.0

2.0

Complex Fertilizers

including Calcium

Ammonium Nitrate,

Ammonium Nitrate &

Ammonium

Nitrophosphate

Fertilizers

Plants

Commissioned

January 1, 1982

onwards

Plants

Commissioned

prior to

January 1,

1982

(a)

(b)

pH

6.5 – 8.0

6.5 – 8.0

Ammonical Nitrogen

50

75

Free Ammonical

Nitrogen

100

100

Nitrate Nitrogen

20

20

Cynide as CN

0.2

0.2

Vanadium as V

0.2

0.2

Arsenic as As

0.2

0.2

*

To be complied with at the outlet of fluoride removal unit. If the recipient system so

demand, fluoride as F shall be limited to 1.5 mg/l.

**

To be complied with at the outlet of Chromate removal unit.

The Environment (Protection) Rules, 1986

422

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Phosphate as P

5

5

Oil and Grease

10

10

Suspended Solids

10

100

*

Fluoride as F

10

10

**

Hexavalent

Chromium as Cr.

0.1

0.1

**Total Chromium as

Cr

2.0

2.0

Straight Phosphate

Fertilizers

pH

7.0 –9.0

Phosphate as P

5

Oil and Grease

10

Suspended Solids

100

*Fluoride as F

10

**Hexavalent

Chromium as Cr

0.1

**Total Chromium as

Cr

2.0

Emissions

Phosphatic Fertilizers

(Fluorides and

Particulate matter

emission)

Phosphorice acid

manufacturing unit

Granulation mixing

and grinding of rock

phosphate

25 milligramme per normal cubic

metre as total Fluoride 150

milligramme per normal cubic metre

of particulate matter.

Urea (Particulate matter

emission)

Pricing tower

Commissioned prior to

01.01.1982

Commissioned after

1.1.1982

150 milligramme per normal cubic

metre of 2 kilogramme per tone of

product.

50 milligramme per normal cubic

metre or 0.5 kilogramme per tonne of

product

*

To be complied with at the outlet of fluoride removal unit. If the recipient system so demand, fluoride as F shall

be limited to 1.5 mg/l.

**

To be complied with at the outlet of Chromate removal unit.

The Environment (Protection) Rules, 1986

423

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

1

[18.

OMITTED

19.

CALCIUM CARBIDE

Particulate Matter

Emission

- Kiln

250 milligramme per normal cubic

metre.

- Arc Furnace

150 milligramme per normal cubic

metre.

20.

CARBON BLACK

Particulate matter

Emission

150 milligramme per normal cubic

metre.

21.

COPPER, LEAD AND

ZINC SMELTING

Particulate Matter

Emission in

Concentrator

150 milligramme per normal cubic

metre.

Emission of Oxides of

Sulphur in Smelter &

convertor

Off-gases must be utilized for

sulphuric acid manufacture. The

limits of sulphur dioxide emission

from stock shall not exceed 4

kilogramme per tonne of concentrated

(one hundred per cent acide

produced).

22.

NITRIC ACID

(EMISSION OXIDES

OF NITROGEN)

Emission of Oxides of

Nitrogen

3 kilogramme of oxides of nitrogen

per tonne of weak acid (before

concentration) produced.

2

[23.

SULPHURIC ACID

PLANT

Emission standards

Limiting

concentration in

mg/Nm

3

,

unless stated

Plant capacity for

100% concentration

of Sulphuric Acid

(tonne/day)

1

Sr. No.18 relating to “Aluminum” and entries relating thereto omitted by Rule 2(II) of the Environment

(Protection) First Amendment Rules, 2006 notified by G.S.R. 46(E), dated 3.2.2006.

2

Substituted by Rule 2(I) of the Environment (Protection) Third Amendment Rules, 2008 notified by G.S.R.

344(E), dated 7.5.2008.

The Environment (Protection) Rules, 1986

424

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

Existing Unit

New Unit

Sulphur dioxide

(SO

2

) upto 300

1370

1250

Above 300

1250

950

Acid Mist/Sulphur

Up to 300

90

70

Trioxide

Above 300

70

50

Note:

(i) Scrubbing units shall have on-line pH meters with auto recording facility.

(ii) The height of the stack emitting sulphur-dioxide or acid mist shall be of minimum of

30 metre or as per the formula H=14(Q)

(0.3)

(whichever is more). Where ―H‖ is the

height of stack in metre; and ―Q‘ is the maximum quantity of SO

2

expected to be

emitted through the stack at 110 per cent rated capacity of the plants and calculated as

per the norms of gaseous emission.

(iii) Plants having more than one stream or unit of sulphuric acid at one location, the

combined capacity of all the streams and units shall be taken into consideration for

determining the stack height and applicability of emission standards.

(iv) Plants having separate stack for gaseous emission for the scrubbing unit, the height of

this stack shall be equal to main stack].

24.

IRON & STEEL

(INTEGRATED)

Particulate Matter

Emission

- Sintering Plant

150 milligramme per normal cubic

metre

- Steel making

-- during normal

operations

150 milligramme per normal cubic

metre.

--during oxygen

lancing

400 milligramme per normal cubic

metre.

- Rolling Mill

150 milligramme per normal cubic

metre.

- Carbon monoxide

from coke oven

3 kilogramme per tonne of coke

produced.

The Environment (Protection) Rules, 1986

425

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

1

25.

THERMAL POWER

PLANTS

Particulate Matter

Emissions :

- generation cpacity

210 MW or more

150 millogramme per normal cubic

metre.

- generation capacity

less than 210 MW

350 milligramme per normal cubic

metre.

26.

NATURAL RUBBER

INDUSTRY

Concentrations in the effluents not to

exceed milligramme per litre (except

for pH) 44

o

C

- Discharge into inland

surface water

Colour & odour

Absent

pH

6.0 – 9.0

BOD

50

COD

250

Oil and Grease

10

Sulphides

2

Total Kjeldahl

Nitrogen

100

Dissolved phosphate

(as P)

5

Suspended Solids

100

Dissolved solids

(inorganic)

2100

Ammonical Nitrogen

as N

50

Free ammonia (as

NH

3

)

5

-Disposal on land for

irrigation

Colour and Odour

Absent

pH

6.0 – 8.0

BOD

100

COD

250

Oil & Grease

10

Suspended Solids

200

Dissolved solids

2100

1

S. No. 25 and 26 and entries relating thereto inserted vide S.O. 8(E) dt. 3.1.89 published in the Gazette No. 7

dated. 3.1.89.

Corrections in rule 2 against S.No. 26 made vide corrigendum No. S.O. 190 (E) dt. 15.3.89 published in the

Gazette no. 126 dt. 15.3.89.

Depending upon the requirement of local situation, such as protected area, the State Pollution Control Board

and other implementation agencies under the Environment (Protection) Act, 1986 may prescribed a limit of 150

milligramme per normal cubic meter, irrespective of generation capacity of the plant.

The Environment (Protection) Rules, 1986

426

Sr.

No.

Industry

Parameter

Standards

1

2

3

4

1

[

2

27.

ASBESTOS

MANUFACTURING

UNITS (INCLUDING

ALL PROCESSES

INVOLVING THE

USE OF ASBESTOS)

- Pure Asbestos

material

0.5 fibre */cc for one year from the

date of notification

0.2 fibre */cc after one year from the

date of notification]

- Total Dust

2 mg/m

3

(normal)

28.

CALOR ALKALI

(CAUSTIC SODA)

EMISSIONS

Concentration in mg/m

3

(normal)

(a) Mercury Cell

Mercury (from

hydrogen gas holder

stack)

0.2

(b) All processes

Chlorine (from hypo

tower)

15.0

(c) All processes

Hydro chloric acid

vapours and mist

(from hydro chloric

acid plant)

35.0

29.

LARGE PULP AND

PAPER

EMISSIONS

Concentration in mg/m

3

(normal)

Particulate matter

250

**

H

2

S

10

30.

INTEGRATED IRON

AND STEEL

PLANTS:

I. EMISSIONS

(a) Coke Oven

Particulate mater

50

(b) Refractory

material plant

Particulate matter

150

II. EFFLUENTS

Concentration in mg/l except for pH.

(a) Coke oven

By product plant.

pH

6.0 – 8.0

Suspended Solids