Cyber Supply Chain Risk Management (SCRM) Engineer,

a Security Specialty within System Security Engineering

Abstract #23774

Holly Dunlap, Holly.Dunlap@Raytheon.com

Raytheon Missiles & Defense, System Security Engineering

Cyber SCRM Engineering SME

December 2021

© 2021 Raytheon Technologies Corporation.

All rights reserved.

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Agenda

• What is Cyber SCRM?

• Adversary

• Global Supply Chain Risks

• Customer Requirements

• Standards

• Future State Vision

• Integrating Cyber SCRM into RTX – It’s a journey.

• Raytheon Cyber SCRM Role & Responsibility

• Customer Program Perspective Example

• Key Takeaways

2

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Key Definitions

• Supply Chain Risk. The risk that an adversary may sabotage, maliciously introduce unwanted

function, or otherwise subvert the design, integrity, manufacturing, production, distribution,

installation, operation, or maintenance of a system so as to surveil, deny, disrupt, or otherwise

degrade the function, use, or operation of such system.

– DoDI 5200.44, Protection of Mission Critical Functions toAchieve Trusted Systems and Networks (TSN)

• Cyber Supply Chain Risk Management (C-SCRM) is the process of identifying, assessing, and mitigating the

risks associated with the distributed and interconnected nature of ICT product and service supply chains. It

covers the entire lifecycle of a system (including design, development, distribution, deployment, acquisition,

maintenance, and destruction) as supply chain threats and vulnerabilities may intentionally or unintentionally

compromise an ICT product or service at any stage of the lifecycle. Department Homeland Security (DHS)

• Cyber Supply Chain Risk Management (C-SCRM) is a systematic process for managing cyber supply chain

risk exposures, threats, and vulnerabilities throughout the supply chain and developing response strategies to

the cyber supply chain risks presented by the supplier, the supplied products and services, or the supply chain.

– DRAFT NIST 800-161 Rev 1, Cyber Supply Chain Risk Management Practices for Systems and Organizations

* ICT – Information Communication Technology

3

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

The Threat is Real…

The Adversary has moved from attacking our systems directly to attacking our supply chain.

Chinese DH-10

Russia’s A-50

U.S. HUMVEE

ALARM

TOMAHAWK

U.S. Reaper

Battlefield Losses: Yugoslav Museum of Aviation

China’s Yìlóng-1

These are Not Cooperative R&D Efforts

4

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Cyber Supply Chain Risk Management

The Global Suppl in presents th eatest attack surface to our national security systems.

CYBER

roelectronics is DOD's new No. 1 technology priority,

ping hypersonics to No. 3 – Inside Defense June 29, 2020

We are responsib he authenticity & integrity of the components integrated into our systems.

5

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Key Protection Activities to Improve Cyber Resiliency

Cyber SCRM Requirements are

derived from DoDI 5200.44

Program Protection & Cybersecurity

DoDI 5000.02, Enclosure 3 & 14

DoDM 5200.01, Vol. 1-4

DoDI 5200.39

DoDM 5200.45

DoDI 8500.01

DoDI 8510.01

DoDI 5200.44 DoDI 5230.24

Technology Components Information

What: A capability element that

contributes to the warfighters’

technical advantage (CPI)

What: Mission-critical functions

and components

What: Information about the

program, system, designs,

processes, capabilities and end-

items

Key Protection Activity:

• Software Assurance

• Hardware Assurance/Trusted

Foundry

Key Protection Activity:

• Anti-Tamper

• Defense Exportability Features

• CPI Protection List

Key Protection Activity:

• Classification

• Supply Chain Risk Management • Export Controls

• Anti-counterfeits

• Joint Federated Assurance

Center (JFAC)

• Information Security

• Joint Acquisition Protection &

Exploitation Cell (JAPEC)

• Acquisition Security Database

Goal: Prevent the compromise and Goal: Protect key mission

Goal: Ensure key system and

program data is protected from

adversary collection

loss of CPI

components from malicious

activity

Protecting Warfighting Capability Throughout the Lifecycle

Policies, guidance and white papers are found at our initiatives site: http://www.acq.osd.mil/se/initiatives/init_pp-sse.html

6

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Relationship of DoD Acquisition Policies and Industry

Best Practices often referred to as Standards

Supply Chain Risk Management

NIST SP 800-37

Applying the Risk Management

k (RMF) to Federal Information

Systems: A Security Life

NIST SP 800-160 Vol 1

Systems Security Engineering: Considerations for a

Multi-disciplinary Approach in the Engineering of

Trustworthy Secure Systems

Rev.2

NIST SP 800-53

NIST SP 800-161

Cyber

Security and Privacy Controls forInformation

Systems and Organizations

Supply Chain Risk ManagementPractices for

Federal Information Systems & Organizations

Rev.5

Draft Rev.1

CNSSI 1253

SECURITY CATEGORIZATION AND CONTROL SELECTION

FOR NATIONAL SECURITY SYSTEMS

NIST Internal Report 7622

Notional Supply Chain Risk Management

Practices for Federal Information Systems

Predicting future updates to include NIST SP 800-53 Rev 5

* Predecessor to NIST SP 800-161

7

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Raytheon Future State

Cyber Supply Chain Risk Management

Operational Systems of Systems

System Functional Decomposition

SwA Raytheon Vulnerability Assessment Process

(Guide & Enabler)

Supply Chain Trade Space Options

Assessments

Critical Components

Identification & Categorization

Management

Filtering

& Rating

Software /

Firmware (?)

(Hardware, Software, Firmware)

Internal Test Capability

Catalog & Guide

Hardware / Firmware

Test

Capability 1,2,3,4,5….

Applicable Type of Component

Level of Risk Mitigation

Architecture Internal

External

Internal

Design

Testing

Or External

Internal Risk Mitigation

Product Catalog

8

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

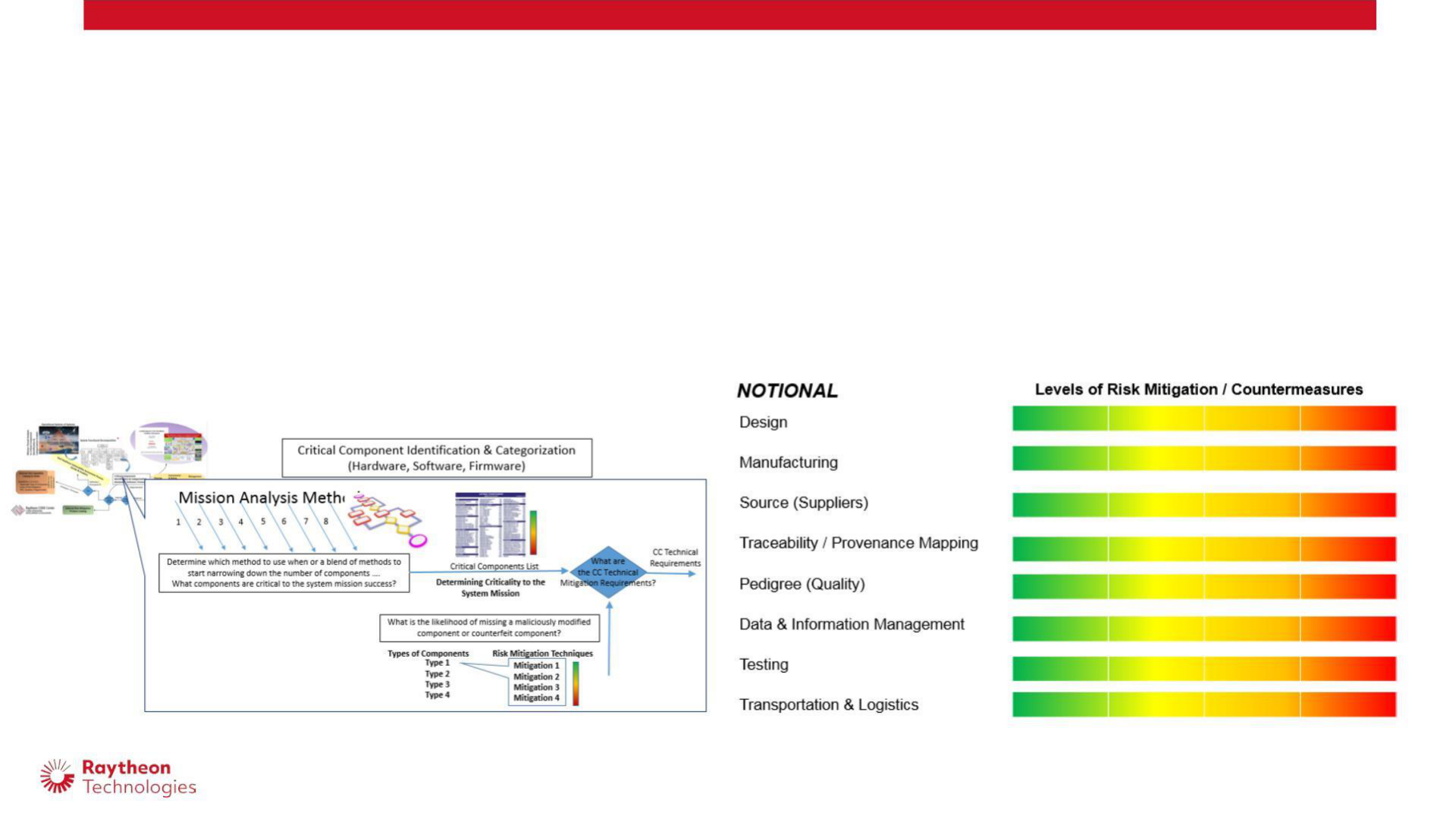

Catalog Trade Based Cyber SCRM Options

Programs need a range of risk mitigations to address supply chain risks for our System Mission Critical Components.

• Tiered Component Design Features

• Tiered Criteria andAudits for Levels of Security in Manufacturing

• Tiered Criteria and Evaluation of Suppliers

• Tiered Criteria for Critical Component Pedigree

• Tiered Requirements to Flow to Suppliers for How to Manage Data & Information

• Tiered Criteria and Options for Test Requirements and Evidence by the Type of Component

• Tiered Criteria and Options for Transportation & Logistics Mitigations.

9

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Cyber Supply Chain Risk Management

NIST SP 800-161

Supply Chain Risk Management Practices for Federal Information Systems & Organizations

Customer

Requirements

Initial System

Architecture

Initial System

Architecture

•

•

System Functions

Mission Threads

•

•

System Functional

Capability

CONOPS

Program protection implementation is

an iterative process that matures over

the lifecycle.

RTN Security

Architecture Framework

PPiP

•

•

•

•

•

AT

SCRM

Cybersecurity

OPSEC

SwA

Provides approach and

levels of risk mitigation

(countermeasure

options)

Countermeasure

Selection

Identify & Assess Assess System

Security Risk

Evaluate

Trades

Criticality

Implement

• CPI – Risk = Consequence x

Exposure

Mission Critical Information

Mission Critical Functions

•

•

CPI Identification (Technology)

Mission Critical Information –

Cybersecurity

Mission Critical Functions –

Trusted Systems & Networks

(SCRM & SwA)

• Risk Reduction

(Countermeasures)

Cost

Schedule

Performance

•

•

•

•

•

Validate

& Verify

•

• Components

•

•

Hardware

Software

Likelihood

Risk

Residual

Risk

https://csrc.nist.gov/publications/detail/sp/800-161/final

Raytheon

Program Protection

Threats

Consequence

10

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Raytheon's Integrated Supply Chain Construct

Integrate Cyber SCRM Considerations into Existing Raytheon Supply Chain Methods and Tools

11

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Raytheon’s Cyber SCRM Role OV-1

Enterprise Team

Supplier

Management

Supplier

Assessments

Program

Subcontract

Lead

Supply Chain

Operations

Contracts

(Ts & Cs)

Program Team

Quality Components Safety Reliability

Engineer Engineer Engineer Engineer

SC Tools,

Processes,

Methods

The Cyber SCRM Engineering Lead is responsible for the

program strategy and technical subsystem and component

procurement and subcontracting requirements to address global

supply chain risks.

•

•

•

•

•

•

Cyber SCRM Strategy

System Mission Criticality Analysis for Logic Bearing Critical Component Identification

Bill of Materials Decomposition

Mitigation Evaluation for Procured and Subcontracted Material and Software.

Supplier / Sub Selection Criteria for Cyber SCRM Considerations

Cyber SCRM Asset Management Considerations

Material Program

Manager (MPM)

SC Cyber

SCRM

Engineer ??

SC Cyber

SCRM

DFARS

Cyber SCRM

Engineer

Cyber SCRM Engineer Addresses Global Supply Chain Risks to Program Procurements

13

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Example Raytheon Program Cyber SCRM Perspective

Holly Dunlap

ProgramArchitecture

Program System Design

Security Focus

Leads the holistic approach for integrating and managing the security

risks. Develops a security view within the system architecture.

PPiP (SSE)

Works with System Chief Architect and System Design

Engineers to address Security related requirements via an

iterative process

System Mission Criticality Analysis (incorporates safety & reliability) Results

System Mission Critical Function & System Mission Critical Component

Approach to the

development of

software

Supply Chain Risk

Management Plan

Cybersecurity Software

Development Plan

Works with Chief Engr, SSE, Cybersecurity Lead,

and relevant Program SMEs to identify Critical

Program Information (CPI) and inherited CPI.

Information

protection strategy

Anti-tamper Plan

Strategy

Material Program Strategy

Develops a plan on how to protect CPI.

add to the critical

rity requirements are

r statements of work

Cyber SCRM requires coordination & collaboration with other security

specialties as well as other program plans. It is not necessarily straight forward

and it is not necessarily consistent from program to program regarding which

plans must be coordinated.

Rayt

-notes

WE – Counterfeit Material and Malware Avoidance

Process Requirements.

COTS (GOTS / FOSS)

Management Plan

Coordinates an manages security related technical

requirements to include risk mitigations for subcontractors

and suppliers

AW – Software Quality Assurance Program

Counterfeit

Components Plan

Patch & Vulnerability

Management Plan

GP - Electronic Part and Assembly Counterfeit Risk

Mitigation

Microelectronics Source

Protection Plan

Continuous Monitoring

UK – Certificate of Conformance

Raytheon’s Cyber Supply Chain Risk Management Program Plan Relational Mapping

14

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Distribution Statement A- Approved for public release; distribution is unlimited.

Cyber Supply Chain Risk Management

Key Takeaways

• Adversaries are moving from directly attacking our systems to attacking our more

vulnerable supply chains.

• Cyber SCRM is a new and developing security specialty discipline within System

Security Engineering and Systems Engineering

• Apartnership between Engineering, MissionAssurance, and Supply Chain

organizations is an imperative.

• Cyber SCRM contributes to a holistic approach to program protection and a

Program Protection implementation Plan (PPiP).

15

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

References:

• DoDI 5200.44

– https://www.esd.whs.mil/Portals/54/Documents/DD/issuances/dodi/520044p.pdf?ver=2018-11-08-075800-903

• NIST SP 800-53 Rev 5

– https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.800-53r5.pdf

• NIST SP 800-160

– https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.800-160v1.pdf

• NIST SP 800-161

– https://csrc.nist.gov/publications/detail/sp/800-161/rev-1/draft

• Deliver Uncompromised,AStrategy for Supply Chain Security and Resilience in Response to the

Changing Character of War

– https://www.mitre.org/sites/default/files/publications/pr-18-2417-deliver-uncompromised-MITRE-study-26AUG2019.pdf

16

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Questions?

17

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Holly Dunlap Bio

• BS Electrical Engineering & MBA

• 10 years Nuclear Weapons, National Nuclear SecurityAdministration (NNSA) Kansas City Plant, M&O Honeywell

– 3 Year Rotational Leadership Development Program (10 years experience in 3 years)

•

•

•

Program Manager of B83

Supply Chain 18 months (Rotated every 3 months)

Intelligence Community (Reverse Engineering, Rapid Fielding, Analysis)

– Certified 6 Sigma Black Belt – Microelectronics

• OSD DDR&E Technical Intelligence, Pentagon +4 years

– Emerging & Disruptive Technology. Investment strategy to ensure US technical capability advantage. Work intimately with Anti-tamper ExecutiveAgent, National &

Defense Intelligence Community, and Defense System Developers. Strategic 15 – 20 Year Planning.

• Ktech LaterAcquired by RTN RMS

– USD(I) Contract Supply Chain & Logistics LayeredAnalysis; Data & Information Exploitation. 18 month effort.

• RMS – IDS – RMD (+15 years)

– NDIA System Engineering Division Elected Chair (+13 Committees, +500 members; government, industry, academia, FFRDC)

– NDIA System Security Engineering Committee Chair, +9 years

– Raytheon Systems Engineering Council – Cyber Resiliency & System Security Project Lead

– Cyber Enterprise Campaign

– Cyber Operations Development & Evaluation (CODE) Center

– PI Security & Trustworthy Foundations for Electronics Resurgence (STryFER) IDIQ Contracted Research & Development (CRAD) Proposal

18

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.

Thank you.

19

This document does not contain technology or technical data controlled under either the U.S. International Traffic in Arms Regulations or the U.S. Export Administration Regulations.