Journal of Current Research on Engineering,

Science and Technology

(JoCREST)

ISSN: 2651-2521

Year: 2020

Volume: 6

Issue: 2

doi: 10.26579/jocrest.62

Experimental Investigation of the Effects of Different Adiabatic

Section Lengths on Temperature Distribution in Solar Powered

Gravity Assisted Heat Pipe

Engin ÖZBAŞ

1

& Saba SHABANI

2

Keywords

Heat pipe,

Adiabatic section,

Solar energy.

Abstract

In this study, the effect of the length of the adiabatic section in the gravity

assisted two-phase closed thermosiphon type heat pipe on the heat pipe was

investigated experimentally. For this, four heat pipes with adiabatic zone lengths

of 0cm (a), 5cm (b), 10cm (c) and 15cm (d) were manufactured. Pure water was

used as the working fluid in a, b, c and d heat pipes of the same material and

diameter. Heat pipes were actuated under the same time and conditions with solar

energy in autumn and compared experimentally. The highest condenser

temperatures for a, b, c and d heat pipes were 96.6oC, 74.5oC, 79.8oC and

84.8oC, respectively, in the experiments. While the highest condenser

temperature was reached in (a) heat pipe where there is no adiabatic zone, the

heat pipe with the longest adiabatic zone (d) ranked second.

Article History

Received

28 Nov, 2020

Accepted

30 Dec, 2020

1. Introduction

The use of renewable energy sources is increasing gradually to contribute to the

increasing personal and social energy need with problems such as environmental

pollution and global warming. Solar energy, which is one of the renewable energy

sources, has many applications. As in every system, additional systems can be used

to save energy and increase efficiency in solar energy systems. One of these

additional systems is the heat pipe (Özbaş, 2019: 22). When the literature is

examined, it is seen that there are with wick, without wick, flat plate, loop and

pulsating type heat pipes (Khairnasov and Naumova, 2016: 52). Qu et al,

experimentally investigated heat pipes with adiabatic section shaped as ∩, Ν,

and Ι in their study. For this they manufactured a hybrid flexible oscillating heat

pipes (FOHP) with adiabatic zones made of fluorine rubber material. Deionized

water were used as the working fluid at 50%, 60% and 70% volumetric ratios in

the heat pipes (Qu et al, 2017: 107). Brahim and Jemni investigated the potential

effect of heat pipe adiabatic zone on flow and heat transfer performance of a heat

1

Corresponding Author. ORCID: 0000-0003-4922-7890. Dr, Ondokuz Mayıs University, Yesilyurt

D.C. Vocational School, [email protected]du.tr

2

ORCID: 0000-0001-7483-2254. Master Student, Ondokuz Mayıs University, Graduate School of

Sciences, shaabani.saba@gmail.com

For cited: Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different Adiabatic

Section Lengths on Temperature Distribution in Solar Powered Gravity Assisted Heat Pipe. Journal of Current

Research on Engineering, Science and Technology, 6 (2), 69-78.

Research Article/Araştırma Makalesi

70 Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different

Adiabatic Section Lengths on Temperature Distribution in Solar Powered Gravity

Assisted Heat Pipe

pipe under varying evaporator and condenser conditions. The boundary and

inertia effects of the porous fluid were investigated by the Darcy-Brinkman-

Forchheimer model. A FORTRAN code was developed for the solution of the model

and it was observed that a phase change may occur in the adiabatic region due to

the temperature gradient formed in the porous structure (Brahim and Jemni, 2014:

136). Arab et al, the application of pulsating heat pipes (PHPs) in a solar water

heater (SWH) had investigated. An extra long pulsating heat pipe (ELPHP) has

been designed. The condenser and evaporator sections lengths of the

manufactured heat pipe are 0.8m and 0.96m, respectively, while the length of the

adiabatic zone varies between 0.7m and 1.8m. Four different filling ratios were

compared in the experiments. Four different filling ratios were compared in the

experiments (Arab et al, 2012: 42). A new composite heat pipe (CHP) is proposed

by wrapping the adiabatic part of a conventional heat pipe (HP)with a phase

change material (PCM) in the study by Zhuang et al. Thus, it was aimed to combine

the high thermal conductivity of conventional HP with the high thermal storage

capacity of the PCM. The experimental results showed that with CHP, thermal

performance can be increased and thermal shock can be greatly reduced (Zhuang

et al, 2019: 100). By Czajkowski et al; the effect of different filling ratios (FR) and

different adiabatic section lengths working with different working fluids such as

acetone, ethanol and water in the large-scale pulsating heat pipe (PHP) that can

operate with high heating power up to 2kW has been investigated. As a result of

experiments, it has been shown that the length of adiabatic section does not have a

significant effect on PHP performance for a given working fluid. However, it has

been observed that the effect is different according to different working fluids

(Czajkowski et al, 2020: 165). In this study, the effect of different adiabatic zone

lengths on the temperature distribution in the heat pipe in a gravity assisted two-

phase closed thermosiphon type heat pipe was investigated.

2. Experimental Study

2.1. Gravity Assisted Heat Pipe

Heat Pipe (HP) is a two-phase heat transfer device. Heat transfer is made possible

by taking advantage of the latent enthalpy of the working fluid during the change

of step. It is widely used for various heat flux systems for cooling purposes, such as

fuel cells and electronic devices (Nazari et al, 2018: 32; Ramezanizadeh et al, 2018:

272). Gravity assisted two-phase closed thermosiphon type heat pipe is a pipe with

two ends closed filled with working fluid approximately 5-30% of evaporator's

volume and containing both liquid and gas phases of the working fluid at the same

time. (Faghri, 1995: 6).

Journal of Current Research on Engineering, Science and Technology, 2020, 6 (2), 69-78. 71

Fig. 1. Gravity assisted two-phase closed thermosiphon

Physical mechanism of the heat pipe as seen in Fig. 1 consists of three parts: the

evaporator section, the condenser section and the adiabatic section. In the vapor

phase, the working fluid rises from the interior of the pipe with the influence of the

heat it absorbs from the evaporator region and enters the condenser zone. Here

the working fluid, which transforms into a liquid phase by releasing its heat,

descends from the surface of the pipe to the evaporator region in the shape of a

film by the influence of gravity and completes its cycle (Jafari et al, 2016: 53).

2.2. Experimental Setup

Four heat pipes of the same diameter and material type were manufactured. The

length of the evaporator zone of all heat pipes is 30 cm and the length of the

condenser zone is 15 cm. Fig. 2 shows the manufactured heat pipes.

Fig. 2. The heat pipes

The lengths of the adiabatic zones of each are designed as (a) 0cm, (b) 5cm, (c)

10cm and (d) 15cm, respectively. Heat pipe types and temperature measurement

points are given in Fig. 3. Temperature measurements were made from a total of

four locations, from the midpoints of the condenser and adiabatic zones, and from

the two ends of the evaporator zone.

72 Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different

Adiabatic Section Lengths on Temperature Distribution in Solar Powered Gravity

Assisted Heat Pipe

Fig. 3. The heat pipe types and temperature measurement points

The heat pipes whose preparations have been completed for experimental

comparison are shown in Fig. 4. Adiabatic zones of the heat pipes are well

insulated against heat transfer. Since the temperature distribution in the heat

pipes will be examined, the condenser zones are not coated.

Fig. 4. The heat pipes for the experimental comparison

Solar radiation, ambient temperature and wind speed for the experiment day were

taken from the meteorological station in Yesilyurt DC Vocational School. Type K

thermocouple was used for temperature measurements on the test system and

collected with a UDL100 type data logger. The experiments have been made in the

autumn months at GPS coordinates of 41°14′N and 36°26′E (Samsun, Turkey).

Therefore, in order to benefit more from the sun, the inclination angle of the

systems was set as 41°. In Fig. 5, a general view is given from the experimental

setup.

Journal of Current Research on Engineering, Science and Technology, 2020, 6 (2), 69-78. 73

Fig. 5. A general view from the experimental setup

3. Results

The distribution of meteorological data and insolation values as of 15 October

2020 at the time of the analysis of the experiment is shown in Fig. 6.

Fig. 6. The distribution of meteorological data and insolation values

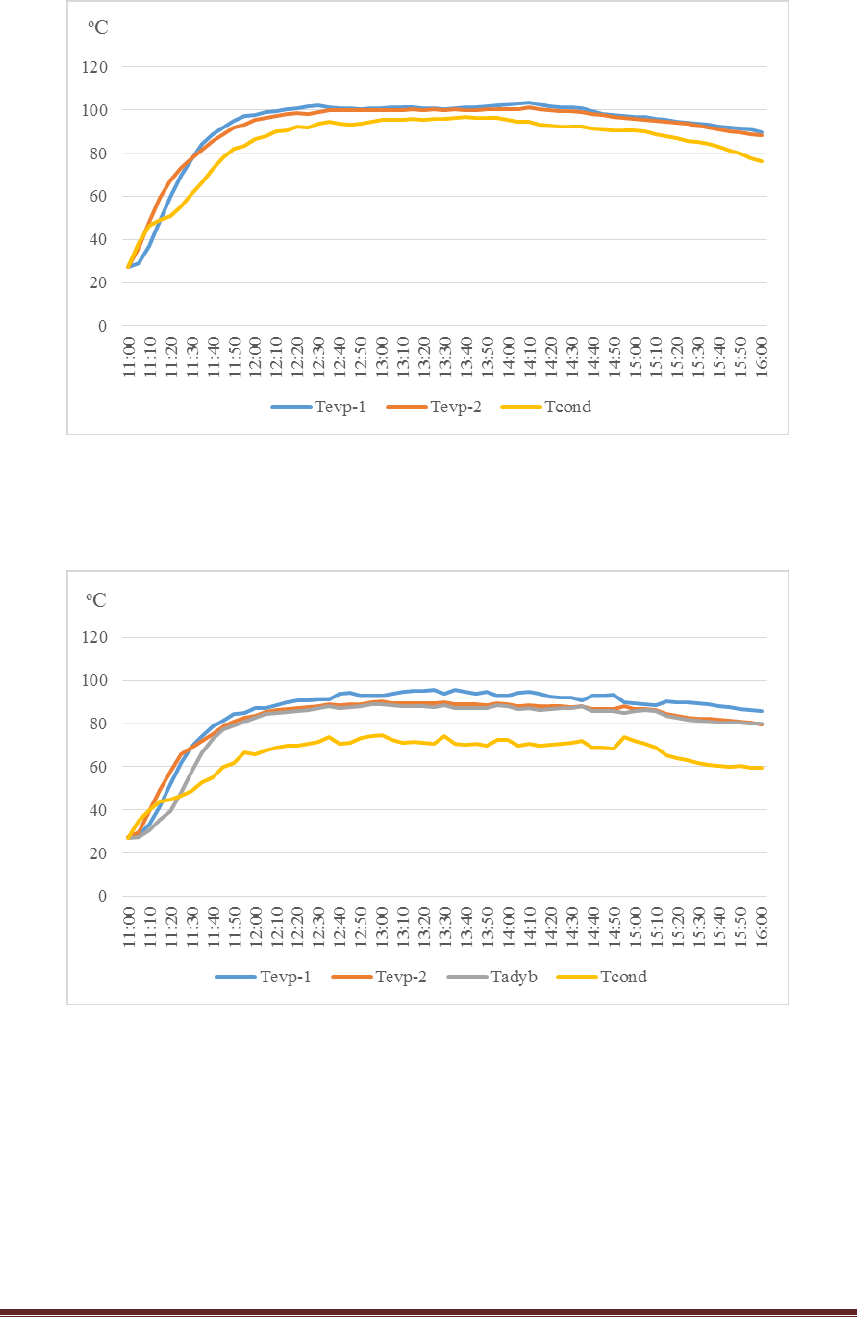

In Figure 7, the temperature distribution of the (a) type heat pipe without

adiabatic zone is given. It is seen that the temperature values of Tevap-1 and

Tevap-2 points are close to each other and are around 100

o

C. The temperature

values of the Tcond point reached around 95

o

C.

74 Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different

Adiabatic Section Lengths on Temperature Distribution in Solar Powered Gravity

Assisted Heat Pipe

Fig. 7. Temperature distribution for (a) type heat pipe

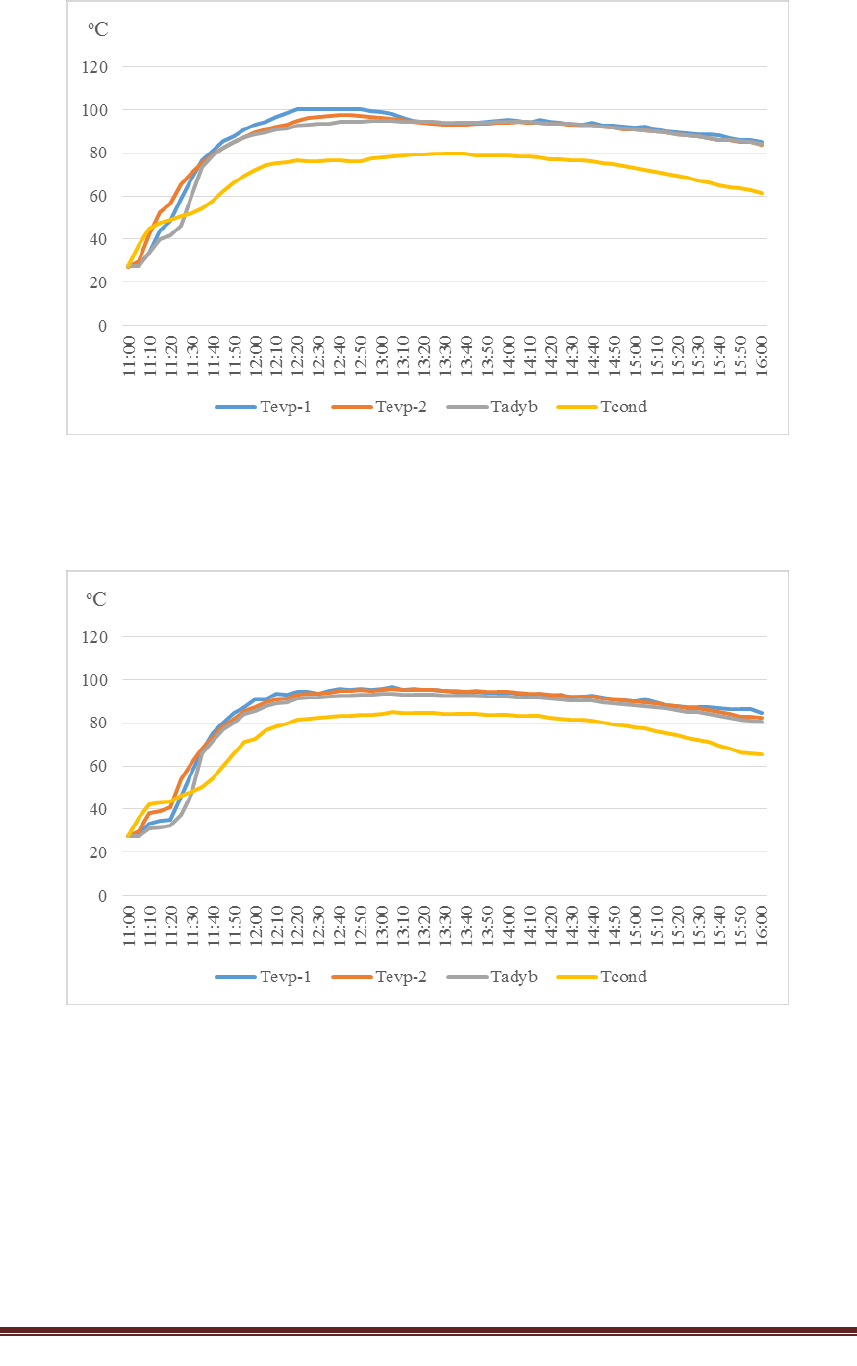

The temperature distribution in the (b) type heat pipe with an adiabatic zone

length of 5cm is as shown in Fig. 8. The temperature of the Tcond point remained

above 70

o

C.

Fig. 8. Temperature distribution for (b) type heat pipe

The distribution of the temperature measurement points of the (c) type heat pipe

with an adiabatic length of 10 cm is indicated in Fig. 9. The temperature values of

the Tcond point in this heat pipe approached 80

o

C.

Journal of Current Research on Engineering, Science and Technology, 2020, 6 (2), 69-78. 75

Fig. 9. Temperature distribution for (c) type heat pipe

In Fig. 10, the temperature distribution on the (d) type heat pipe, which has the

longest adiabatic zone length with 15 cm, is seen. The temperature value of Tcond

point in (d) type heat pipe has reached up to 85

o

C.

Fig. 10. Temperature distribution for (d) type heat pipe

The comparison of the condenser temperature distribution of four heat pipes is

given in Fig. 11. The highest condenser temperature values were reached with (a)

type heat pipe, followed by (d), (c) and (b) type heat pipes, respectively.

76 Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different

Adiabatic Section Lengths on Temperature Distribution in Solar Powered Gravity

Assisted Heat Pipe

Fig. 11. The condenser temperature distribution of a, b, c and d type heat pipes

In Table 1, the insolation values calculated with the hourly meteorological data of

the experiment day are given. Table 2 and Table 3 show the temperature values

measured on a, b, c and d type heat pipes. Experiments were carried out between

11.00-16.00 hours. However, only hourly results are included in the tables.

Table 1. The values of meteorological data and insolation

Time

INSOLATION

Solar Radiation

Ambient Temperature

Wind Speed

(W/m

2

)

(W/m

2

)

(

o

C)

(km/hour)

11:00

406,80

406,80

24,06

7,2

12:00

428,92

440,00

23,86

7,2

13:00

434,26

431,40

23,98

11,5

14:00

424,54

373,60

24,06

10,1

15:00

399,44

275,80

24,04

10,1

16:00

363,30

163,00

23,82

6,5

Table 2. Temperature values of type-a and type-b heat pipes,

o

C

Type-a

Type-b

Time

Tevp-1

Tevp-2

Tcond

Tevp-1

Tevp-2

Tadyb

Tcond

11:00

27,1

27,2

27,2

27,2

27,3

27,1

27,1

12:00

97,8

95,6

86,6

87,2

83,7

82,5

65,9

13:00

100,8

100,0

95,2

93,0

90,1

88,9

74,5

14:00

102,7

100,5

95,6

92,9

89,0

88,0

72,2

15:00

96,6

95,8

90,4

89,3

86,8

85,6

71,8

16:00

89,7

88,1

76,0

85,6

79,7

80,0

59,4

Journal of Current Research on Engineering, Science and Technology, 2020, 6 (2), 69-78. 77

Table 3. Temperature values of type-c and type-d heat pipes,

o

C

Type-c

Type-d

Time

Tevp-1

Tevp-2

Tadyb

Tcond

Tevp-1

Tevp-2

Tadyb

Tcond

11:00

27,3

27,2

27,3

27,3

27,3

27,4

27,3

27,3

12:00

92,9

89,4

88,7

72,3

90,9

87,3

85,4

72,7

13:00

98,7

96,2

94,8

78,0

95,9

95,4

93,3

84,3

14:00

95,2

94,0

94,3

78,7

93,8

94,2

92,1

83,8

15:00

91,6

90,7

90,8

73,1

89,9

89,9

88,1

78,0

16:00

85,1

83,7

84,0

61,3

84,7

82,3

80,6

65,5

In this study, gravity assisted two-phase closed thermosiphon type heat pipes with

different adiabatic zone lengths were investigated. The effect of four different

adiabatic zone lengths as 0cm (a), 5cm (b), 10cm (c) and 15cm (d) on the

temperature distribution on the heat pipe was experimentally compared. The

effect of the length of the adiabatic zone on the heat transfer from the evaporator

zone to the condenser zone was observed under the same conditions and

simultaneously with solar energy. When the temperature distribution on the heat

pipe is examined, it is understood that the heat insulation of the adiabatic region is

provided well. And also when the results are analyzed, it is seen that heat transfer

is very successful in (a) type heat pipe where there is no adiabatic zone. In other

heat pipes, the heat transfer increased with the increase in the length of the

adiabatic zone and the best result was obtained with the (d) type heat pipe. The

heat pipes were run by solar energy. Performance analysis was not made in the

study in which only temperature distribution was examined. A fluid heating can be

done for performance analysis. Since the experiments were carried out in the

autumn, they were made at a tilt angle of 41

o

. The effect of different adiabatic zone

lengths on the heat pipe at different tilt angles can be examined. In the

experimental study, pure water was used as working fluid in heat pipes. These

heat pipes can be experimentally compared with different working fluids such as

nanofluids.

References

Arab, M., Soltanieh, M., Shafii, M.B. (2012), “Experimental investigation of extra-

long pulsating heat pipe application in solar water heaters”, Experimental

Thermal and Fluid Science, pp. 6-15.

Brahim, T. and Jemni, A. (2014), “Effect of the Heat Pipe Adiabatic Region”, Journal

of Heat Transfer, pp. 1-10.

Czajkowski, C., Nowak, A.I., Błasiak, P., Ochman, A., Pietrowicz, S. (2020),

“Experimental study on a large scale pulsating heat pipe operating at high

heat loads, different adiabatic lengths and various filling ratios of acetone,

ethanol, and water”, Applied Thermal Engineering, pp. 1-15.

Faghri, Amir (1995), Heat Pipe Science and Technology, Taylor & Francis,

Washington, DC.

78 Özbaş, E. & Shabani, S. (2020). Experimental Investigation of the Effects of Different

Adiabatic Section Lengths on Temperature Distribution in Solar Powered Gravity

Assisted Heat Pipe

Jafari, D., Franco, A., Filippeschi, S., Marco, P. D. (2016), “Two-phase closed

thermosyphons: A review of studies and solar applications”, Renewable

and Sustainable Energy Reviews, pp. 575-593.

Khairnasov, S.M. and Naumova, A.M. (2016), “Heat Pipes Application to Solar

Energy Systems”, Applied Solar Energy, pp. 47-60.

Nazari, M.A., Ghasempour, R., Shafii, M.B., Ahmadi, M.H. (2018), “Experimental

Investigation of Triton X-100 Solution on Pulsating Heat Pipe Thermal

Performance”, Journal of Thermophysics and Heat Transfer, pp. 1-7.

Özbaş, E. (2019), “Experimental Study of Thermal Performance and Pressure

Differences of Different Working Fluids in Two-phase Closed

Thermosyphons Using Solar Energy”, Journal of Polytechnic, pp. 121-

128.

Qu, J., Li, X., Cui, Y., Wang, Q. (2017), “Design and experimental study on a hybrid

flexible oscillating heat pipe”, International Journal of Heat and Mass

Transfer, pp. 640-645.

Ramezanizadeh, M., Nazari, M.A., Ahmadi, M.H., Açıkkalp, E. (2018), “Application of

nanofluids in thermosyphons: A review”, Journal of Molecular Liquids,

pp. 395-402.

Zhuang, B., Deng, W., Tang, Y., Ding, X., Chen, K., Zhong, G., Yuan, W., Li, Z. (2019),

“Experimental investigation on a novel composite heat pipe with phase

change materials coated on the adiabatic section”, International

Communications in Heat and Mass Transfer, pp. 42-50.

Strategic Research Academy ©

© Copyright of Journal of Current Research on Engineering, Science and

Technology (JoCREST) is the property of Strategic Research Academy and its

content may not be copied or emailed to multiple sites or posted to a listserv

without the copyright holder's express written permission. However, users may

print, download, or email articles for individual use.