Chapter 296-62 WAC

General Occupational Health Standards

_________________________________________________________________________________________________________

Chapter 296-62 WAC

Safety Standards for General Occupational

Health Standards

(Form Number F414-042-000)

This book contains rules for Safety Standards for general occupational health standards, as adopted

under the Washington Industrial Safety and Health Act of 1973 (Chapter 49.17 RCW).

The rules in this book are effective July 2023. A brief promulgation history, set within brackets

at the end of this chapter, gives statutory authority, administrative order of promulgation, and

date of adoption of filing.

TO RECEIVE E-MAIL UPDATES:

• Sign up at

https://public.govdelivery.com/accounts/WADLI/subscriber/new?topic_id=WADLI_19

TO PRINT YOUR OWN PAPER COPY OR TO VIEW THE RULE ONLINE:

• Go to https://www.lni.wa.gov/safety-health/safety-rules/rules-by-chapter/?chapter=62/

DOSH CONTACT INFORMATION:

• Physical address:

7273 Linderson Way

Tumwater, WA 98501-5414

(Located off I-5 Exit 101 south of Tumwater)

• Mailing address:

DOSH Standards and Information

PO Box 44620, Olympia, WA 98504-4620

Information telephone number is 1-800-423-7233

• For all L&I Contact information, visit https://www.lni.wa.gov/agency/contact/

• Also available on the DOSH web site:

• DOSH Core Rules

• Other General Safety and Health Rules

• Industry and Task-specific Rules

• Proposed Rules and Hearings

• Newly adopted Rules and New Rule Information

• DOSH Directives (DD’s)

• See http://www.lni.wa.gov/Safety-Health/

Chapter 296-62 WAC Table of Contents

General Occupational Health Standards

_________________________________________________________________________________________________________

Table of Contents

296-62 WAC

General Occupational Safety and Health

Part Title

Part A General WAC 296-62-005 through 296-62-050

Part B-1 Trade Secrets

Part C-1 Retain Department of Transportation Labeling WAC 296-62-055

through 296-62-05520

Part D Controls and Definitions WAC 96-62-060

Part F Carcinogens WAC 296-62-073 through 296-62-07316

Part G Carcinogens (Specific) WAC 296-62-07329 through 296-62-07477

Part I Airborne Contaminants WAC 296-62-07517 through 296-62-

07660

Part I-1 Asbestos, Tremolite, Anthrophyllite, and Actinolite WAC 296-62-

077 through 296-62-07755

Part I-2 Hexavalent Chromium WAC 296-62-08003 through 296-62-

08029

Part J-1 Physical Agents WAC 296-62-090 through 296-62-09560

Part L Atmospheres and Ventilation WAC 296-62-11015 through 296-

62-13635

Part N Cotton Dust WAC 296-62-14533 through 14543

Part O Coke Ovens WAC 296-62 through 296-62-20029

Part R Hazardous Drugs WAC 296-62-500 through 296-62-50055

Public Health Emergency Reporting WAC 296-600 through 296-

62-609

Statutory Authorities Pages i through xiv

Chapter 296-62 WAC Part A

General Occupational Health Standards General

_________________________________________________________________________________________________________

Part A, Page i

PART A

GENERAL

WAC Page

WAC 296-62-005 Occupational health and environmental

control—Foreword ................................................... 1

WAC 296-62-010 Purpose and scope. ...................................... 1

WAC 296-62-020 Definitions applicable to all sections of this

chapter. ................................................... 1

WAC 296-62-040 Unconstitutionality clause. .......................... 3

WAC 296-62-050 Application for waiver or variances. ........... 3

Chapter 296-62 WAC Part A

General Occupational Health Standards General

_________________________________________________________________________________________________________

Part A, Page 1

WAC 296-62-005 Occupational health and environmental

control--Foreword.

(1) Foreword.

(a) Modern industry is changing at an ever-increasing pace. New inventions, discoveries

and developments cause changes in every facet of the industrial process. In keeping

with this changing technology is the necessity to provide an adequate guide for the

protection of working men and women. This chapter is for the guidance of both labor

and management and to call particular attention to the way in which modernization

and updating of the standards can be accomplished.

(b) This chapter is intended to cover as fully as is practical the environment in which

work is performed. In addition to the suggestions made herein, the services of

modern occupational medicine must also be considered. Occupational medicine with

its specialized techniques for examination, diagnosis, and treatment adds another

protection for the worker as he encounters newly-developed materials and methods.

(c) With the full realization that close cooperation between government and industry,

labor and management, and all the health sciences, is essential, this chapter is

promulgated for the health of all the workmen coming under the jurisdiction of the

department of labor and industries.

(d) This chapter is promulgated in accordance with the applicable requirements as

outlined in the Washington State Administrative Procedure Act (chapter 34.04 RCW)

and other applicable statutes.

WAC 296-62-010 Purpose and scope.

The rules in this chapter are designed to protect the health of employees and help to create a

healthy workplace by establishing requirements to control health hazards. Requirements for

chemical hazard communication programs, workplace lighting levels and exposure records are in

chapter 296-800 WAC, the safety and health core rules.

WAC 296-62-020 Definitions applicable to all sections of this

chapter.

Unless the context indicates otherwise, words used in this chapter shall have the meaning given

in this section.

Adequate or effective. Compliance with terms and intent of these standards.

Appendix. References or recommendations to be used as guides in applying the provisions of

this chapter.

Approved. Approved by the director of the department of labor and industries or his authorized

representative, or by an organization that is specifically named in a rule, such as Underwriters’

Laboratories (UL), Mine Safety and Health Administration (MSHA), or the National Institute for

Occupational Safety and Health (NIOSH).

Chapter 296-62 WAC Part A

General Occupational Health Standards General

_________________________________________________________________________________________________________

Part A, Page 2

Authorized person. A person approved or assigned by the employer to perform a specific type

of duty or duties or to be at a specific location or locations at the job site.

Coal tar pitch volatiles. As used in WAC 296-62-07515, Table I, include the fused polycyclic

hydrocarbons which volatilize from the distillation residues of coal, petroleum, (excluding

asphalt), wood, and other organic matter. Asphalt (CAS 8052-42-4, and CAS 64742-93-4) is not

covered under the “coal tar pitch volatiles” standard.

Competent person. One who is capable of identifying existing and predictable hazards in the

surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees,

and who has authorization to take prompt corrective action to eliminate them.

Department. The department of labor and industries.

Director. The director of the department of labor and industries, or their designated

representative.

Employer. Any person, firm, corporation, partnership, business trust, legal representative, or

other business entity which engages in any business, industry, profession, or activity in this state

and employs one or more employees or who contracts with one or more persons, the essence of

which is the personal labor of such person or persons and includes the state, counties, cities, and

all municipal corporations, public corporations, political subdivisions of the state, and charitable

organizations: Provided, That any persons, partnership, or business entity not having employees,

and who is covered by the industrial insurance act shall be considered both an employer and an

employee.

Hazard. That condition, potential or inherent, which can cause injury, death, or occupational

disease.

Occupational disease. Such disease or infection as arises naturally and proximately out of

employment.

Qualified. One who, by possession of a recognized degree, certificate, or professional standing,

or who by extensive knowledge, training, and experience, has successfully demonstrated ability

to solve or resolve problems relating to the subject matter, the work, or the project.

Shall or must. Mandatory.

Should or may. Recommended.

Suitable. That which fits, or has the qualities or qualifications to meet a given purpose,

occasion, condition, function, or circumstance.

Worker, personnel, person, employee, and other terms of like meaning. Unless the context

of the provision containing such term indicates otherwise, mean an employee of an employer

who is employed in the business of their employer whether by way of manual labor or otherwise

and every person in this state who is engaged in the employment of or who is working under an

independent contract the essence of which is their personal labor for an employer whether by

manual labor or otherwise.

Work place. Any plant, yard, premises, room, or other place where an employee or employees

are employed for the performance of labor or service over which the employer has the right of

access or control. This includes, but is not limited to, all work places covered by industrial

insurance under Title 51 RCW, as now or hereafter amended.

Chapter 296-62 WAC Part A

General Occupational Health Standards General

_________________________________________________________________________________________________________

Part A, Page 3

Abbreviations used in this chapter:

ANSI. American National Standards Institute.

ASHRE. American Society of Heating and Refrigeration Engineers.

BTU. British thermal unit.

BTUH. British thermal unit per hour.

CFM. Cubic feet per minute.

CFR. Code of Federal Register.

CGA. Compressed Gas Association.

ID. Inside diameter.

MCA. Manufacturing Chemist Association or Chemical Manufacturer Association

(CMA).

NEMA. National Electrical Manufacturing Association.

NFPA. National Fire Protection Association.

OD. Outside diameter.

WAC. Washington Administrative Code.

WISHA. Washington Industrial Safety and Health Act (chapter 80, Laws of 1973).

WAC 296-62-040 Unconstitutionality clause.

In the event that any section, paragraph, sentence, clause, phrase or work of this chapter is

declared unconstitutional or invalid for any reason the remainder of said standard or this chapter

must not be affected thereby.

WAC 296-62-050 Application for waiver or variances.

See WAC 296-900-11005, Applying for a variance.

Chapter 296-62 WAC Part B-1

General Occupational Health Standards Trade Secrets

_________________________________________________________________________________________________________

Part B, Page i

PART B-1

TRADE SECRETS

Note: Chapter 296-62 WAC, General occupational health standards, Part B-

1, Trade secrets, (WAC 296-62-05301 through 296-62-05325 has

been repealed. Please refer to WAC 296-901-14018 Trade secrets.

Chapter 296-62 WAC Part C-1

General Occupational Health Standards Retain Department of Transportation Labeling

_________________________________________________________________________________________________________

Part C-1, Page i

PART C-1

RETAIN DEPARTMENT OF TRANSPORTATION

LABELING

WAC Page

WAC 296-62-055 Retain labeling required by the department

of Transportation. ....................................................................... 1

WAC 296-62-05510 Scope. ........................................................................................... 1

WAC 296-62-05520 Retain readily visible DOT labeling. ............................................... 1

Chapter 296-62 WAC Part C-1

General Occupational Health Standards Retain Department of Transportation Labeling

_________________________________________________________________________________________________________

Part C-1, Page 1

WAC 296-62-055 Retain labeling required by the department

of transportation.

Your responsibility: To make sure DOT-required labeling on packages and containers in your

workplace is retained to alert employees of potentially hazardous contents.

Note: Terms used in this rule are defined by the USDOT in Title 49 of the

Code of Federal Regulations (CFR) Part 171. To access the CFR visit

http://www.dot.gov

WAC 296-62-05510 Scope.

This chapter applies to packages, freight containers, rail freight cars, motor vehicles, and

transport vehicles required to be marked, or labeled by the U.S. Department of Transportation in

Title 49 of the CFR, Parts 171-180.

WAC 296-62-05520 Retain readily visible DOT labeling.

You must retain readily visible DOT labeling as specified in Table 1.

If you receive

Retain DOT markings, placards and labels UNTIL:

• Packages of

hazardous materials

• Hazardous materials are sufficiently removed

– Packaging must be

■ cleaned of residue

■ purged of vapors

• Freight containers

• Rail freight cars

• Motor vehicles

• Transport vehicles

• Hazardous materials are sufficiently removed

• Nonbulk packages

that will not be

reshipped

• You replace the DOT labeling with labeling that

complies with WAC 296-901-140 Hazard

communication

Chapter 296-62 WAC Part D

General Occupational Health Standards Controls and Definitions

_________________________________________________________________________________________________________

Part D, Page i

PART D

CONTROLS AND DEFINITIONS

WAC Page

WAC 296-62-060 Control requirements in addition to those

specified. ................................................... 1

Chapter 296-62 WAC Part D

General Occupational Health Standards Controls and Definitions

_________________________________________________________________________________________________________

Part D, Page 1

WAC 296-62-060 Control requirements in addition to those

specified.

Note: The requirements in this section apply only to agriculture. The

requirements for general industry relating to control requirements have

been moved to chapter 296-800 WAC, Safety and health core rules.

(1) In those cases where no acceptable standards have been derived for the control of

hazardous conditions, every reasonable precaution must be taken to safeguard the health of

the worker whether provided herein or not.

(2) Preservation of records.

(a) Scope and application. This section applies to each employer who makes, maintains

or has access to employee exposure records or employee medical records.

(b) Definitions.

Employee exposure record. A record of monitoring or measuring which

contains qualitative or quantitative information indicative of employee exposure

to toxic materials or harmful physical agents. This includes both individual

exposure records and general research or statistical studies based on information

collected from exposure records.

Employee medical record. A record which contains information concerning

the health status of an employee or employees exposed or potentially exposed to

toxic materials or harmful physical agents. These records may include, but are

not limited to:

(A) The results of medical examinations and tests;

(B) Any opinions or recommendations of a physician or other health

professional concerning the health of an employee or employees; and

(C) Any employee medical complaints relating to workplace exposure.

Employee medical records include both individual medical records and

general research or statistical studies based on information collected from

medical records.

(c) Preservation of records. Each employer who makes, maintains, or has access to

employee exposure records or employee medical records must preserve these records.

(d) Availability of records. The employer must make available, upon request, to the

director, department of labor and industries, or his designee, all employee exposure

records and employee medical records for examination and copying.

(e) Effective date. This standard shall become effective thirty days after filing with the

code reviser.

(3) Monitoring of employees. The department must use industrial hygiene sampling methods

and techniques including but not limited to personal monitoring devices and equipment

approved by the director or his designee for the purpose of establishing compliance with

chapter 296-62 WAC.

Chapter 296-62 WAC Part D

General Occupational Health Standards Controls and Definitions

_________________________________________________________________________________________________________

Part D, Page 2

(a) The employer must permit the director or his designee to monitor and evaluate any

workplace or employee in accordance with all provisions of this subsection.

(b) The employer must not prevent or discourage an employee from cooperating with the

department by restricting or inhibiting their participation in the use of personal

monitoring devices and equipment in accordance with all provisions of this

subsection.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page i

PART F

CARCINOGENS

WAC Page

WAC 296-62-073 Carcinogens-Scope and application. .......... 1

WAC 296-62-07302 Communication of hazards. ........................................................... 1

WAC 296-62-07304 Definitions. .................................................................................... 2

WAC 296-62-07306 Requirements for areas containing carcinogens listed in WAC 296-

62-07302. ........................................................................................................ 3

WAC 296-62-07308 General regulated area requirements. ........................................... 6

WAC 296-62-07310 Signs, information and training. ..................................................... 8

WAC 296-62-07312 Reports. ......................................................................................... 9

WAC 296-62-07314 Medical surveillance. ................................................................... 10

WAC 296-62-07316 Premixed solutions. ..................................................................... 11

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 1

WAC 296-62-073 Carcinogens-Scope and application.

(1) All sections of this chapter which include WAC 296-62-073 in the section number apply to

the manufacturing, processing, repackaging, releasing, handling or storing of carcinogens.

(2) This section shall not apply to solid or liquid mixtures containing less than 0.1 percent by

weight or volume of the carcinogens listed in WAC 296-62-07302.

WAC 296-62-07302 Communication of hazards.

(1) Hazard communication.

(a) Chemical manufacturers, importers, distributors, and employers must comply with all

requirements of the Hazard Communication Standard (HCS), WAC 296-901-140 for

each carcinogen listed in subsection (2) of this section.

(b) In classifying the hazards of carcinogens listed in subsection (2) of this section, at

least the hazards listed in subsection (2) of this section are to be addressed.

(c) Employers must include the carcinogens listed in subsection (2) of this section in the

hazard communication program established to comply with the HCS, WAC 296-901-

140. Employers must ensure that each employee has access to labels on containers of

the carcinogens listed in subsection (2) of this section and to safety data sheets, and is

trained in accordance with the requirements of HCS and subsection (2) of this

section.

(2) List of carcinogens:

(a) 4-Nitrobiphenyl: Cancer (CAS 92-93-3).

(b) Alpha-Naphthylamine: Cancer; skin irritation; and acute toxicity effects (CAS 134-

32-7).

(c) Methyl chloromethyl ether: Cancer; skin; eye and respiratory effects; acute toxicity

effects; and flammability (CAS 107-30-2).

(d) 3,3'-Dichlorobenzidine (and its salts): Cancer and skin sensitization (CAS 91-94-1).

(e) Bis-Chloromethyl ether: Cancer; skin, eye, and respiratory tract effects; acute

toxicity effects; and flammability (CAS 542-88-1).

(f) Beta-Naphthylamine: Cancer and acute toxicity effects (CAS 91-59-8).

(g) Benzidine: Cancer and acute toxicity effects (CAS 92-87-5).

(h) 4-Aminodiphenyl: Cancer (CAS 92-67-1).

(i) Ethyleneimine: Cancer; mutagenicity; skin and eye effects; liver effects; kidney

effects; acute toxicity effects; and flammability (CAS 151-56-4).

(j) Beta-Propiolactone: Cancer; skin irritation; eye effects; and acute toxicity effects

(CAS 57-57-8).

(k) 2-Acetylaminofluorene: Cancer (CAS 53-96-3).

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 2

(l) 4-Dimethylaminoazo-benzene: Cancer, skin effects; and respiratory tract irritation

(CAS 60-11-7).

(m) N-Nitrosodimethylamine: Cancer; liver effects; and acute toxicity effects (CAS 62-

75-9).

WAC 296-62-07304 Definitions.

The definitions set forth in this section apply throughout WAC 296-62-073 through 296-62-

07316.

Absolute filter. Is one capable of retaining 99.97 percent of a mono disperse aerosol of 0.3

micron size particles.

Authorized employee. An employee whose duties require him to be in the regulated area and

who has been specifically assigned to those duties by the employer.

Clean change room. A room where employees put on clean clothing and/or protective

equipment in an environment free of carcinogens listed in WAC 296-62-07302. The clean

change room shall be contiguous to and have an entry from a shower room, when the shower

room facilities are otherwise required in this section.

Closed system. An operation involving carcinogens listed in WAC 296-62-07302 where

containment prevents the release of carcinogens.

Decontamination. The inactivation of a carcinogen listed in WAC 296-62-07302 or its safe

disposal.

Disposal. The safe removal of a carcinogen listed in WAC 296-62-07302 from the work

environment.

Emergency. An unforeseen circumstance or set of circumstances resulting in the release of a

carcinogen which may result in exposure to or contact with any carcinogen listed in WAC 296-

62-07302.

External environment. Any environment external to regulated and nonregulated areas.

Isolated system. A fully enclosed structure other than the vessel of containment of a listed

carcinogen which is impervious to the passage of listed carcinogens and which would prevent the

entry of carcinogens into regulated areas, nonregulated areas, or the external environment,

should leakage or spillage from the vessel of containment occur.

Laboratory-type hood. A device enclosed on three sides and the top and bottom, designed and

maintained so as to draw air inward at an average linear face velocity of 150 feet per minute with

a minimum of 125 feet per minute, designed, constructed and maintained such that an operation

involving a listed carcinogen within the hood does not require the insertion of any portion of any

employees' body other than his hands and arms.

Nonregulated area. Any area under the control of the employer where entry and exit is neither

restricted nor controlled.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 3

Open-vessel system. An operation involving listed carcinogens in an open vessel, which is not

in an isolated system, a laboratory-type hood, nor in any other system affording equivalent

protection against the entry of carcinogens into regulated areas, nonregulated areas, or the

external environment.

Protective clothing. Clothing designed to protect an employee against contact with or exposure

to listed carcinogens.

Regulated area. An area where entry and exit is restricted and controlled.

WAC 296-62-07306 Requirements for areas containing carcinogens listed in WAC

296-62-07302.

(1) A regulated area must be established by an employer where listed carcinogens are

manufactured, processed, used, repackaged, released, handled or stored.

(2) All such areas must be controlled in accordance with the requirements for the following

category or categories describing the operation involved:

(a) Isolated systems. Employees working with carcinogens within an isolated system

such as a “glove box.” must wash their hands and arms upon completion of the

assigned task and before engaging in other activities not associated with the isolated

system.

(b) Closed system operation. Within regulated areas where carcinogens are stored in

sealed containers, or contained in a closed system including piping systems with any

sample ports or openings closed while carcinogens are contained within:

Access must be restricted to authorized employees only;

Employees must wash hands, forearms, face and neck upon each exit from the

regulated areas, close to the point of exit and before engaging in other activities.

(c) Open vessel system operations. Open vessel system operations as defined in WAC

296-62-07304 are prohibited.

(d) Transfer from a closed system. Charging or discharging point operations, or

otherwise opening a closed system. In operations involving “laboratory-type hoods,”

or in locations where a carcinogen is contained in an otherwise “closed system,” but

is transferred, charged, or discharged into other normally closed containers, the

provisions of this section shall apply.

Access must be restricted to authorized employees only;

Each operation must be provided with continuous local exhaust ventilation so

that air movement is always from ordinary work areas to the operation. Exhaust

air must not be discharged to regulated areas, nonregulated areas or the external

environment unless decontaminated. Clean makeup air must be introduced in

sufficient volume to maintain the correct operation of the local exhaust system.

Employees must be provided with, and required to wear, clean, full body

protective clothing (smocks, coveralls, or long-sleeved shirt and pants), shoe

covers and gloves prior to entering the regulated area.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 4

Each employee engaged in handling operations involving the following

carcinogens must be provided with and required to wear and use a NIOSH-

certified self-contained breathing apparatus that has a full facepiece and is

operated in a pressure-demand or other positive-pressure mode, or any supplied

air respirator that has a full facepiece and is operated in a pressure-demand or

other positive pressure mode in combination with an auxiliary self-contained

positive-pressure breathing apparatus as required in chapter 296-842 WAC. A

respirator affording higher levels of protection than this respirator may be

substituted.

(A) Methyl Chloromethyl Ether;

(B) bis-Chloromethyl Ether;

(C) Ethylenemine;

(D) beta-Propiolactone;

(E) 4-Amino Diphenyl.

Each employee engaged in handling operations involving the following

carcinogens must be provided with, and required to wear and use, NIOSH-

certified air-purifying, half-mask respirator with particulate filters as required in

chapter 296-842 WAC. A respirator affording higher levels of protection than

this respirator may be substituted.

(A) 4-Nitrobiphenyl;

(B) alpha-Naphthylamine;

(C) 4-4'Methylene bis (2-Chloroaniline);

(D) 3,3'Dichlorobenzidine (and its salts);

(E) beta-Naphthylamine;

(F) Benzidine;

(G) 2-acetylamino fluroene;

(H) 4-imethylaminoazobenzene;

(I) n-nitrosodimethylamine.

must be provided with, and required to wear and use, a half-face, filter-type respirator

certified for solid or liquid particulates with minimum efficiency rating of 95% as

required in chapter 296-842 WAC. A respirator affording higher levels of protection

than this respirator may be substituted.

Prior to each exit from a regulated area, employees must remove and leave

protective clothing and equipment at the point of exit and at the last exit of the

day, to place used clothing and equipment in impervious containers at the point

of exit for purposes of decontamination or disposal. The contents of such

impervious containers must be identified, as required under WAC 296-62-

07302.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 5

Employees must wash hands, forearms, face and neck on each exit from the

regulated area, close to the point of exit, and before engaging in other activities.

Employees must shower after the last exit of the day.

Drinking fountains are prohibited in the regulated area.

(e) Maintenance and decontamination activities. In cleanup of leaks or spills,

maintenance or repair operations on contaminated systems or equipment, or any

operations involving work in an area where direct contact with carcinogens could

result, each authorized employee entering the area must:

Be provided with and required to wear, clean, impervious garments, including

gloves, boots and continuous-air supplied hood in accordance with WAC 296-

800-160, and respiratory protective equipment required by this chapter 296-842

WAC;

Be decontaminated before removing the protective garments and hood;

Shower upon removing the protective garments and hood.

(f) Laboratory activities. The requirements of this subdivision shall apply to research

and quality control activities involving the use of carcinogens listed in WAC 296-62-

07302.

Mechanical pipetting aids must be used for all pipetting procedures.

Experiments, procedures and equipment which could produce aerosols must be

confined to laboratory-type hoods or glove boxes.

Surfaces on which carcinogens are handled must be protected from

contamination.

Contaminated wastes and animal carcasses must be collected in impervious

containers which are closed and decontaminated prior to removal from the work

area. Such wastes and carcasses must be incinerated in such a manner that no

carcinogenic products are released.

All other forms of listed carcinogens must be inactivated prior to disposal.

Laboratory vacuum systems must be protected with high efficiency scrubbers or

with disposable absolute filters.

Employees engaged in animal support activities must be:

(A) Provided with, and required to wear, a complete protective clothing

change, clean each day, including coveralls or pants and shirt, foot covers,

head covers, gloves, and appropriate respiratory protective equipment or

devices; and

(B) Prior to each exit from a regulated area, employees must remove and

leave protective clothing and equipment at the point of exit and at the last

exit of the day, to place used clothing and equipment in impervious

containers at the point of exit for purposes of decontamination or disposal.

The contents of such impervious containers must be identified as required

under WAC 296-62-07310 (2) and (3).

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 6

(C) Required to wash hands, forearms, face and neck upon each exit from the

regulated area close to the point of exit, and before engaging in other

activities; and

(D) Required to shower after the last exit of the day.

Employees, other than those engaged only in animal support activities, each day

must be:

(A) Provided with and required to wear a clean change of appropriate

laboratory clothing, such as a solid front gown, surgical scrub suit, or fully

buttoned laboratory coat.

(B) Prior to each exit from a regulated area, employees must remove and

leave protective clothing and equipment at the point of exit and at the last

exit of the day, to place used clothing and equipment in impervious

containers at the point of exit for purposes of decontamination or disposal.

The contents of such impervious containers shall be identified as required

under WAC 296-62-07310 (2) and (3).

(C) Required to wash hands, forearms, face and neck upon each exit from the

regulated area close to the point of exit, and before engaging in other

activities.

Air pressure in laboratory areas and animal rooms where carcinogens are

handled and bioassay studies are performed must be negative in relation to the

pressure in surrounding areas. Exhaust air must not be discharged to regulated

areas, nonregulated areas or the external environment unless decontaminated.

There must not be any connection between regulated areas and any other areas

through the ventilation system.

A current inventory of the carcinogens must be maintained.

Ventilated apparatus such as laboratory-type hoods, must be tested at least

semiannually or immediately after ventilation modification or maintenance

operations, by personnel fully qualified to certify correct containment and

operation.

WAC 296-62-07308 General regulated area requirements.

(1) Respirator program. The employer must implement a respiratory protection program as

required in chapter 296-62 WAC, Part E (except WAC 296-62-07130(1) and (5) and 296-

62-07131), which covers each employee required by this chapter to use a respirator.

(2) Emergencies. In an emergency, immediate measures including, but not limited to, the

requirements of (a), (b), (c), (d) and (e) of this subsection must be implemented.

(a) The potentially affected area must be evacuated as soon as the emergency has been

determined.

(b) Hazardous conditions created by the emergency must be eliminated and the

potentially affected area must be decontaminated prior to the resumption of normal

operations.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 7

(c) Special medical surveillance by a physician must be instituted within twenty-four

hours for employees present in the potentially affected area at the time of the

emergency. A report of the medical surveillance and any treatment must be included

in the incident report, in accordance with WAC 296-62-07312(2).

(d) Where an employee has a known contact with a listed carcinogen, such employee

must shower as soon as possible, unless contraindicated by physical injuries.

(e) An incident report on the emergency must be reported as provided in WAC 296-62-

07312(2).

(3) Hygiene facilities and practices.

(a) Storage or consumption of food, storage or use of containers of beverages, storage or

application of cosmetics, smoking, storage of smoking materials, tobacco products or

other products for chewing, or the chewing of such products, are prohibited in

regulated areas.

(b) Where employees are required by this section to wash, washing facilities must be

provided in accordance with WAC 296-800-230.

(c) Where employees are required by this section to shower, shower facilities must be

provided.

One shower must be provided for each ten employees of each sex, or numerical

fraction thereof, who are required to shower during the same shift.

Body soap or other appropriate cleansing agents convenient to the showers must

be provided as specified in WAC 296-800-230, of the safety and health core

rules.

Showers must be provided with hot and cold water feeding a common discharge

line.

Employees who use showers must be provided with individual clean towels.

(d) Where employees wear protective clothing and equipment, clean change rooms must

be provided and must be equipped with storage facilities for street clothes and

separate storage facilities for the protective clothing for the number of such

employees required to change clothes.

(e) Where toilets are in regulated areas, such toilets must be in a separate room.

(4) Contamination control.

(a) Regulated areas, except for outdoor systems, must be maintained under pressure

negative with respect to nonregulated areas. Local exhaust ventilation may be used to

satisfy this requirement. Clean makeup air in equal volume must replace air

removed.

(b) Any equipment, material, or other item taken into or removed from a regulated area

must be done so in a manner that does not cause contamination in nonregulated areas

or the external environment.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 8

(c) Decontamination procedures must be established and implemented to remove

carcinogens from the surfaces of materials, equipment and the decontamination

facility.

(d) Dry sweeping and dry mopping are prohibited.

WAC 296-62-07310 Signs, information and training.

(1) Signs.

(a) The employer must post signs at entrances to regulated areas. The signs must bear

the legend:

DANGER

(CHEMICAL IDENTIFICATION)

MAY CAUSE CANCER

AUTHORIZED PERSONNEL ONLY

(b) The employer must post signs at entrances to regulated areas containing operations

covered in WAC 296-62-07306 (2)(e). The signs must bear the legend:

DANGER

(CHEMICAL IDENTIFICATION)

MAY CAUSE CANCER

WEAR AIR-SUPPLIED HOODS, IMPERVIOUS SUITS, AND PROTECTIVE

EQUIPMENT IN THIS AREA

AUTHORIZED PERSONNEL ONLY

(c) Appropriate signs and instructions must be posted at the entrance to, and exit from,

regulated areas, informing employees of the procedures that must be followed in

entering and leaving a regulated area.

(2) Prohibited statements. No statements shall appear on or near any required sign, label, or

instruction that contradicts or detracts from the effect of any required warning, information

or instruction.

(3) Training and indoctrination.

(a) Each employee prior to being authorized to enter a regulated area, must receive a

training and indoctrination program including, but not necessarily limited to:

The nature of the carcinogenic hazards of listed carcinogens, including local

and systemic toxicity;

The specific nature of the operation involving carcinogens which could result in

exposure;

The purpose for and application of the medical surveillance program, including,

as appropriate, methods of self-examination;

The purpose for and application of decontamination practices and purposes;

The purpose for and significance of emergency practices and procedures;

The employee's specific role in emergency procedures;

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 9

Specific information to aid the employee in recognition and evaluation of

conditions and situations which may result in the release of listed carcinogens;

The purpose for and application of specific first-aid procedures and practices;

A review of this section at the employee's first training and indoctrination

program and annually thereafter.

(b) Specific emergency procedures must be prescribed, and posted, and employees, must

be familiarized with their terms, and rehearsed in their application.

(c) All materials relating to the program must be provided upon request to the director.

WAC 296-62-07312 Reports.

(1) Operations. Not later than October 30, 1974, the information required in (a), (b), (c) and

(d) of this subsection must be reported in writing to the Department of Labor and

Industries, WISHA Services Division, Policy and Technical Services, P.O. Box 44610,

Olympia, WA 98504-4610. Any change in the information must also be reported in

writing within 15 calendar days of the change.

(a) A brief description and in plant location of the area(s) regulated and the address of

each regulated area;

(b) The name(s) and other identifying information as to the presence of listed

carcinogens in each regulated area;

(c) The number of employees in each regulated area, during normal operations including

maintenance activities; and

(d) The manner in which a carcinogen is present in each regulated area; e.g., whether it is

manufactured, processed, used, repackaged, released, stored, or otherwise handled.

(2) Incidents. Incidents which result in the release of a listed carcinogen into any area where

employees may be potentially exposed must be reported in accordance with this subsection.

(a) The occurrence of the incident, including any facts obtainable at that time, as well as

a report on any medical treatment of affected employees, must be reported within 24

hours to the Department of Labor and Industries, WISHA Services Division, Policy

and Technical Services, P.O. Box 44610, Olympia, WA 98504-4610.

(b) A written report must be filed with the Department of Labor and Industries, WISHA

Services Division, Policy and Technical Services, P.O. Box 44610, Olympia, WA

98504-4610, within 15 calendar days after the incident occurs, and must include:

A specification of the amount of material released, the amount of time involved,

and an explanation of the procedure used in determining this figure;

A description of the area involved, and the extent of known and possible

employee exposure and area contamination;

A report of any medical treatment of affected employees, and any medical

surveillance program implemented; and

An analysis of the circumstances of the incident, and measures taken or to be

taken, with specific completion dates, to avoid further similar releases.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 10

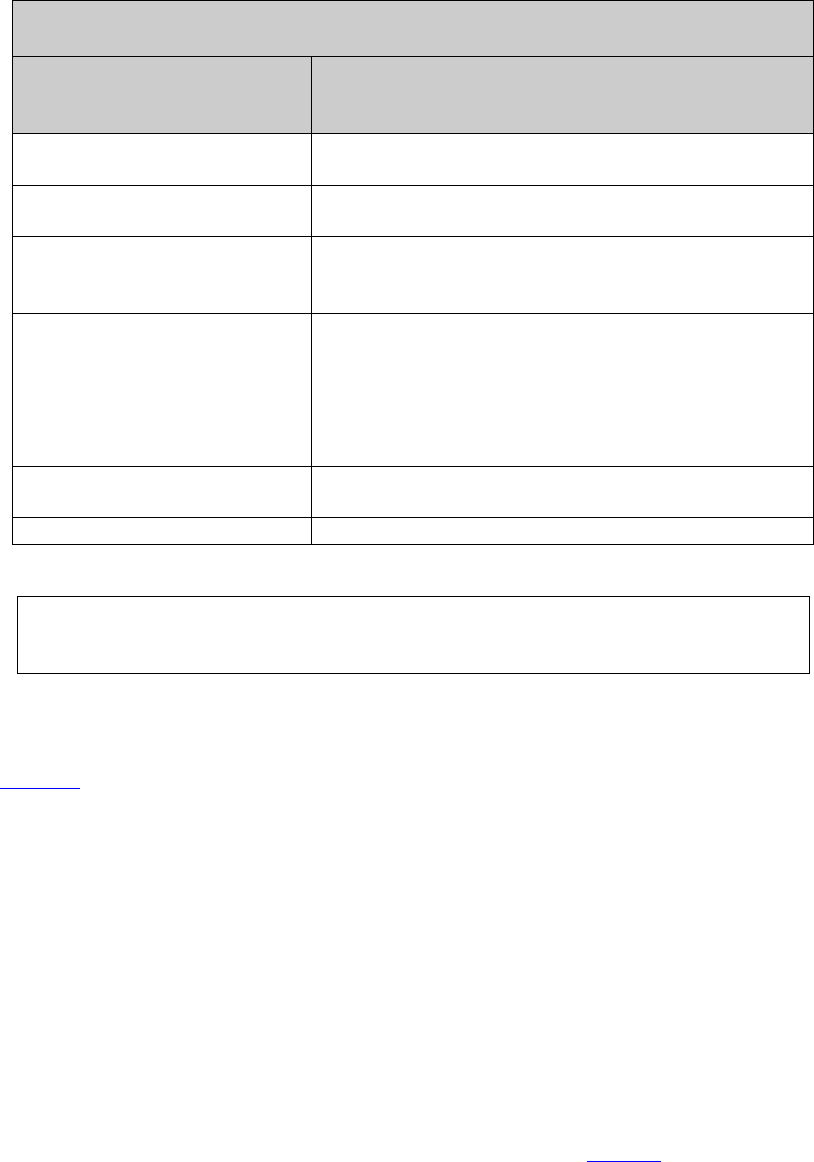

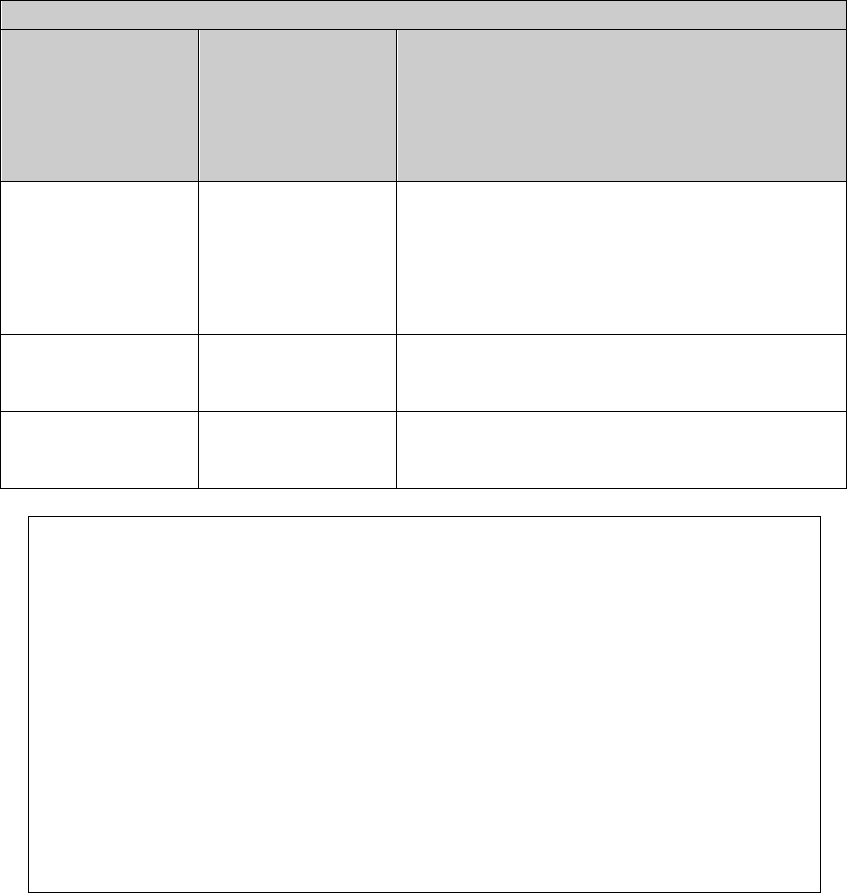

Carcinogen Standard Report

Company:____________________

Plant Address:________________

Date:________________________

Prepared by:_______________________

Title:______________________________

Command and

Other

Identifying

Information

Description of

Inplant

Location of

Regulated Area*

Number of

Employees

In each

Regulated area*

Normally

Maintenance

Manner** In

Which

Compound is

Present in

Each Regulated

Area*

* See WAC 296-62-07304 for definition of “regulated area.”

** Indicated whether manufactured, processed, used, repackaged, released, stored, or if

otherwise handled (describe).

WAC 296-62-07314 Medical surveillance.

(1) At no cost to the employee, a program of medical surveillance must be established and

implemented for employees considered for assignment to enter regulated areas, and for

authorized employees.

(2) Examinations.

(a) Before an employee is assigned to enter a regulated area, a preassignment physical

examination by a physician must be provided and must include a personal history of

the employee and/or their family and occupational background, including genetic and

environmental factors.

Taking of employees’ medical history and background history must be

considered to be a routine part of standard medical practice.

This provision does not require “genetic testing” of any employee.

This provision does not require the exclusion of otherwise qualified employees

from jobs on the basis of genetic factors.

(b) Authorized employees must be provided periodic physical examination, not less often

than annually, following the preassignment examination.

(c) In all physical examinations, the examining physician must be requested to consider

whether there exist conditions of increased risk, including reduced immunological

competence, pregnancy, cigarette smoking, and those undergoing treatment with

steroids or cytotoxic agents.

(3) Records.

(a) Employers of employees examined pursuant to this subdivision must maintain

complete and accurate records of all such medical examinations. Records must be

maintained for the duration of the employee's employment. The employer must

ensure that medical records are maintained and made available in accordance with

chapter 296-802 WAC, Employee medical and exposure records.

Chapter 296-62 WAC Part F

General Occupational Health Standards Carcinogens

_________________________________________________________________________________________________________

Part F, Page 11

(b) Records required by this section must be provided upon request to employees,

designated representatives, and the director in accordance with chapter 296-802

WAC.

(c) Any employer who requests a physical examination of an employee or prospective

employee as required by this section must obtain from the physician a statement of the

employee's suitability for employment in the specific exposure.

WAC 296-62-07316 Premixed solutions.

Where 4,4'-Methylene bis (2-chloroaniline) is present only in a single solution at a temperature

not exceeding 220°F. the establishment of a regulated area is not required; however:

(1) Only authorized employees shall be permitted to handle such materials.

(2) Each day employees must be provided with and required to wear a clean change of

protective clothing (smocks, coveralls, or long-sleeved shirts and pants), gloves and other

protective garments and equipment necessary to prevent contact with the solution in the

process used.

(3) Employees must remove and leave protective clothing and equipment when leaving the

work area at the end of the work day, or at any time solution is spilled on such clothing or

equipment. Used clothing and equipment must be placed in impervious containers for

purposes of decontamination or disposal. The contents of such impervious containers must

be identified, as required under WAC 296-62-07310 (2) and (3).

(4) Employees must wash hands and face after removing such clothing and equipment and

before engaging in other activities.

(5) Employees assigned to work covered by this section must be deemed to be working in

regulated areas for the purposes of WAC 296-62-07308 (1), (2)(a) and (b), and (3)(c) and

(d), WAC 296-62-07310, 296-62-07312 and 296-62-07314.

(6) Work areas where solution may be spilled must be:

(a) Covered daily or after any spill with a clean covering; or

(b) Clean thoroughly, daily and after any spill.

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page i

Part G

Carcinogens (Specific)

WAC Page

WAC 296-62-07329 Vinyl chloride. ................................................................................ 1

WAC 296-62-07336 Acrylonitrile. ................................................................................... 8

WAC 296-62-07337 Appendix A--Substance safety data sheet for acrylonitrile. .......... 21

WAC 296-62-07338 Appendix B--Substance technical guidelines for acrylonitrile. ...... 25

WAC 296-62-07339 Appendix C--Medical surveillance guidelines for acrylonitrile. ..... 30

WAC 296-62-07340 Appendix D--Sampling and analytical methods for acrylonitrile. .. 32

WAC 296-62-07342 1,2-Dibromo-3-chloropropane. ..................................................... 43

WAC 296-62-07343 Appendix A--Substance safety data sheet for DBCP. .................. 54

WAC 296-62-07344 Appendix B--Substance technical guidelines for DBCP. .............. 57

WAC 296-62-07346 Appendix C--Medical surveillance guidelines for DBCP. ............. 61

WAC 296-62-07355 Ethylene oxide. Scope and application. ...................................... 64

WAC 296-62-07357 Definitions. ................................................................................... 64

WAC 296-62-07359 Permissible exposure limits (PEL). .............................................. 65

WAC 296-62-07361 Exposure monitoring. ................................................................... 65

WAC 296-62-07363 Regulated areas. ......................................................................... 67

WAC 296-62-07365 Methods of compliance. ............................................................... 67

WAC 296-62-07367 Respiratory protection and personal protective equipment. ......... 68

WAC 296-62-07369 Emergency situations. ................................................................. 69

WAC 296-62-07371 Medical surveillance. ................................................................... 70

WAC 296-62-07373 Communication of EtO hazards. .................................................. 72

WAC 296-62-07375 Recordkeeping............................................................................. 73

WAC 296-62-07377 Observation of monitoring. ........................................................... 75

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page ii

WAC Page

WAC 296-62-07381 Appendices. ................................................................................. 75

WAC 296-62-07383 Appendix A--Substance safety data sheet for ethylene oxide

(nonmandatory). ............................................................................................................ 75

WAC 296-62-07385 Appendix B--Substance technical guide for ethylene

oxide (nonmandatory). .................................................................................................. 82

WAC 296-62-07387 Appendix C--Medical surveillance guidelines for ethylene oxide

(nonmandatory). ...................................................................................................... 85

WAC 296-62-07389 Appendix D--Sampling and analytical methods for ethylene oxide

(nonmandatory). ............................................................................................................ 88

WAC 296-62-074 Cadmium .................................................... 103

WAC 296-62-07401 Scope. ....................................................................................... 103

WAC 296-62-07403 Definitions. ................................................................................. 103

WAC 296-62-07405 Permissible exposure limit (PEL). .............................................. 104

WAC 296-62-07407 Exposure monitoring. ................................................................. 104

WAC 296-62-07409 Regulated areas. ....................................................................... 105

WAC 296-62-07411 Methods of compliance. ............................................................. 106

WAC 296-62-07413 Respirator protection. ................................................................ 108

WAC 296-62-07415 Emergency situations. ............................................................... 109

WAC 296-62-07417 Protective work clothing and equipment. ................................... 109

WAC 296-62-07419 Hygiene areas and practices. .................................................... 111

WAC 296-62-07421 Housekeeping. ........................................................................... 111

WAC 296-62-07423 Medical surveillance. ................................................................. 112

WAC 296-62-07425 Communication of cadmium hazards. ........................................ 123

WAC 296-62-07427 Recordkeeping........................................................................... 125

WAC 296-62-07429 Observation of monitoring. ......................................................... 126

WAC 296-62-07433 Appendices. ............................................................................... 127

WAC 296-62-07441 Appendix A--substance safety data sheet--Cadmium. ............... 127

WAC 296-62-07443 Appendix B--Substance technical guidelines for cadmium. ....... 141

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page iii

WAC Page

WAC 296-62-07447 Appendix D--Occupational health history interview with reference

to cadmium exposure directions. ................................................................................. 146

WAC 296-62-07449 Appendix E--Cadmium in workplace atmospheres. ................... 150

WAC 296-62-07451 A short description of Appendix F to 29 CFR 1910.1027--

Nonmandatory protocol for biological monitoring. ....................................................... 175

WAC 296-62-07460 1,3-Butadiene. ........................................................................... 176

Appendix A. Substance Safety Data Sheet For 1,3-Butadiene (Non-Mandatory) ...... 191

Appendix B. Substance Technical Guidelines for 1,3-Butadiene (Non-Mandatory) ... 195

Appendix C. Medical Screening and Surveillance for 1,3-Butadiene (Non-Mandatory) . 9

Appendix D: Sampling and Analytical Method for 1,3-Butadiene (Non-Mandatory) ... 202

APPENDIX E: Reserved. ........................................................................................... 210

APPENDIX F, MEDICAL QUESTIONNAIRES, (Non-mandatory) ............................... 210

1,3-Butadiene (BD) Health Update Questionnaire ...................................................... 214

WAC 296-62-07470 Methylene chloride. .................................................................... 217

WAC 296-62-07473 Appendix A. Substance Safety Data Sheet and Technical

Guidelines for Methylene Chloride .............................................................................. 235

WAC 296-62-07475 Appendix B. Medical Surveillance for Methylene Chloride ........ 241

WAC 296-62-07477 Appendix C. Questions and answers--methylene chloride in

furniture stripping......................................................................................................... 250

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 1

WAC 296-62-07329 Vinyl chloride.

(1) Scope and application.

(a) This section includes requirements for the control of employee exposure to vinyl

chloride (chloroethene), Chemical Abstracts Service Registry No. 75014.

(b) This section applies to the manufacture, reaction, packaging, repackaging, storage,

handling or use of vinyl chloride or polyvinyl chloride, but does not apply to the

handling or use of fabricated products made of polyvinyl chloride.

(c) This section applies to the transportation of vinyl chloride or polyvinyl chloride

except to the extent that the department of transportation may regulate the hazards

covered by this section.

(2) Definitions.

(a) Action level. A concentration of vinyl chloride of 0.5 ppm averaged over an 8-hour

work day.

(b) Authorized person. Any person specifically authorized by the employer whose

duties require them to enter a regulated area or any person entering such an area as a

designated representative of employees for the purpose of exercising an opportunity

to observe monitoring and measuring procedures.

(c) Director. The director of department of labor and industries or their designated

representative.

(d) Emergency. Any occurrence such as, but not limited to, equipment failure, or

operation of a relief device which is likely to, or does, result in massive release of

vinyl chloride.

(e) Fabricated product. A product made wholly or partly from polyvinyl chloride, and

which does not require further processing at temperatures, and for times, sufficient to

cause mass melting of the polyvinyl chloride resulting in the release of vinyl chloride.

(f) Hazardous operation. Any operation, procedure, or activity where a release of

either vinyl chloride liquid or gas might be expected as a consequence of the

operation or because of an accident in the operation, which would result in an

employee exposure in excess of the permissible exposure limit.

(g) Polyvinyl chloride. Polyvinyl chloride homopolymer or copolymer before such is

converted to a fabricated product.

(h) Vinyl chloride. Vinyl chloride monomer.

(3) Permissible exposure limit.

(a) No employee may be exposed to vinyl chloride at concentrations greater than 1 ppm

averaged over any 8-hour period, and

(b) No employee may be exposed to vinyl chloride at concentrations greater than 5 ppm

averaged over any period not exceeding 15 minutes.

(c) No employee may be exposed to vinyl chloride by direct contact with liquid vinyl

chloride.

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 2

(4) Monitoring.

(a) A program of initial monitoring and measurement must be undertaken in each

establishment to determine if there is any employee exposed, without regard to the

use of respirators, in excess of the action level.

(b) Where a determination conducted under subdivision (a) of this subsection shows any

employee exposures without regard to the use of respirators, in excess of the action

level, a program for determining exposures for each such employee must be

established. Such a program:

Must be repeated at least monthly where any employee is exposed, without

regard to the use of respirators, in excess of the permissible exposure limit.

Must be repeated not less than quarterly where any employee is exposed,

without regard to the use of respirators, in excess of the action level.

May be discontinued for any employee only when at least two consecutive

monitoring determinations, made not less than 5 working days apart, show

exposures for that employee at or below the action level.

(c) Whenever there has been a production, process or control change which may result in

an increase in the release of vinyl chloride, or the employer has any other reason to

suspect that any employee may be exposed in excess of the action level, a

determination of employee exposure under subdivision (a) of this subsection must be

performed.

(d) The method of monitoring and measurement must have an accuracy (with a

confidence level of 95 percent) of not less than plus or minus 50 percent from 0.25

through 0.5 ppm, plus or minus 35 percent from over 0.5 ppm through 1.0 ppm, plus

or minus 25 percent over 1.0 ppm, (methods meeting these accuracy requirements are

available from the director).

(e) Employees or their designated representatives must be afforded reasonable

opportunity to observe the monitoring and measuring required by this subsection.

(5) Regulated area.

(a) A regulated area must be established where:

Vinyl chloride or polyvinyl chloride is manufactured, reacted, repackaged,

stored, handled or used; and

Vinyl chloride concentrations are in excess of the permissible exposure limit.

(b) Access to regulated areas must be limited to authorized persons.

(6) Methods of compliance. Employee exposures to vinyl chloride must be controlled to at or

below the permissible exposure limit provided in subsection (3) of this section by

engineering, work-practice, and personal protective controls as follows:

(a) Feasible engineering and work-practice controls must immediately be used to reduce

exposures to at or below the permissible exposure limit.

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 3

(b) Wherever feasible engineering and work-practice controls which can be instituted

immediately are not sufficient to reduce exposures to at or below the permissible

exposure limit, they must nonetheless be used to reduce exposures to the lowest

practicable level, and must be supplemented by respiratory protection in accordance

with subsection (7) of this section. A program must be established and implemented

to reduce exposures to at or below the permissible exposure limit, or to the greatest

extent feasible, solely by means of engineering and work-practice controls, as soon as

feasible.

(c) Written plans for such a program must be developed and furnished upon request for

examination and copying to the director. Such plans must be updated at least every

six months.

(7) Respiratory protection.

(a) General. For employees who use respirators required by this section, the employer

must provide each employee an appropriate respirator that complies with the

requirements of this section.

(b) Respirator program. The employer must develop, implement, and maintain a

respiratory protection program as required in chapter 296-842 WAC, Respirators,

which covers each employee required by this chapter to use a respirator.

EXCEPTION: The requirements in WAC 296-842 13005 that address change out of

vapor or gas respirator cartridges or canisters.

(c) Respirator selection. The employer must:

Select and provide to employees appropriate respirators as specified in this

section and WAC 296-842-13005 in the respirator rule.

Provide organic vapor cartridges that have a service life of at least one hour

when employees use air-purifying respirators in vinyl chloride concentrations

up to 10 parts per million (ppm).

Make sure the following respirators, when selected, are equipped with a canister

with a service life of at least 4 hours when used in vinyl chloride concentrations

up to 25 ppm:

(A) Helmet, hood, or full-facepiece PAPRs or

(B) Gas masks with a front-or back-mounted canister.

(d) Where air-purifying respirators are used:

Air-purifying canisters or cartridges must be replaced prior to the expiration of

their service life or the end of the shift in which they are first used, whichever

occurs first, and

A continuous monitoring and alarm system must be provided when

concentrations of vinyl chloride could reasonably exceed the allowable

concentrations for the devices in use. Such system must be used to alert

employees when vinyl chloride concentrations exceed the allowable

concentrations for the devices in use, and

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 4

Respirators specified for higher concentrations may be used for lower

concentration.

(8) Hazardous operations.

(a) Employees engaged in hazardous operations, including entry of vessels to clean

polyvinyl chloride residue from vessel walls, must be provided and required to wear

and use:

Respiratory protection in accordance with subsections (3) and (7) of this

section; and

Protective garments to prevent skin contact with liquid vinyl chloride or with

polyvinyl chloride residue from vessel walls. The protective garments must be

selected for the operation and its possible exposure conditions.

(b) Protective garments must be provided clean and dry for each use.

(c) Emergency situations. A written operational plan for emergency situations must be

developed for each facility storing, handling, or otherwise using vinyl chloride as a

liquid or compressed gas. Appropriate portions of the plan must be implemented in

the event of an emergency. The plan must specifically provide that:

Employees engaged in hazardous operations or correcting situations of existing

hazardous releases must be equipped as required in (a) and (b) of this

subsection;

Other employees not so equipped must evacuate the area and not return until

conditions are controlled by the methods required in subsection (6) of this

section and the emergency is abated.

(9) Training. Each employee engaged in vinyl chloride or polyvinyl chloride operations must

be provided training in a program relating to the hazards of vinyl chloride and precautions

for its safe use.

(a) The program must include:

The nature of the health hazard from chronic exposure to vinyl chloride

including specifically the carcinogenic hazard;

The specific nature of operations which could result in exposure to vinyl

chloride in excess of the permissible limit and necessary protective steps;

The purpose for, proper use, and limitations of respiratory protective devices;

The fire hazard and acute toxicity of vinyl chloride, and the necessary

protective steps;

The purpose for and a description of the monitoring program;

The purpose for and a description of, the medical surveillance program;

Emergency procedures:

(A) Specific information to aid the employee in recognition of conditions

which may result in the release of vinyl chloride; and

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 5

(B) A review of this standard at the employee's first training and

indoctrination program, and annually thereafter.

(b) All materials relating to the program must be provided upon request to the director.

(10) Medical surveillance. A program of medical surveillance must be instituted for each

employee exposed, without regard to the use of respirators, to vinyl chloride in excess of

the action level. The program must provide each such employee with an opportunity for

examinations and tests in accordance with this subsection. All medical examinations and

procedures must be performed by or under the supervision of a licensed physician and must

be provided without cost to the employee.

(a) At the time of initial assignment, or upon institution of medical surveillance;

A general physical examination must be performed with specific attention to

detecting enlargement of liver, spleen or kidneys, or dysfunction in these

organs, and for abnormalities in skin, connective tissues and the pulmonary

system (see Appendix A).

A medical history must be taken, including the following topics:

(A) Alcohol intake,

(B) Past history of hepatitis,

(C) Work history and past exposure to potential hepatotoxic agents, including

drugs and chemicals,

(D) Past history of blood transfusions, and

(E) Past history of hospitalizations.

A serum specimen must be obtained and determinations made of:

(A) Total bilirubin,

(B) Alkaline phosphatase,

(C) Serum glutamic oxalacetic transaminase (SGOT),

(D) Serum glutamic pyruvic transaminase (SGPT), and

(E) Gamma glustamyl transpeptidase.

(b) Examinations provided in accordance with this subdivision must be performed at

least:

Every 6 months for each employee who has been employed in vinyl chloride or

polyvinyl chloride manufacturing for 10 years or longer; and

Annually for all other employees.

(c) Each employee exposed to an emergency must be afforded appropriate medical

surveillance.

(d) A statement of each employee's suitability for continued exposure to vinyl chloride

including use of protective equipment and respirators, must be obtained from the

examining physician promptly after any examination. A copy of the physician's

statement must be provided each employee.

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 6

(e) If any employee's health would be materially impaired by continued exposure, such

employee must be withdrawn from possible contact with vinyl chloride.

(f) Laboratory analyses for all biological specimens included in medical examinations

must be performed in laboratories licensed under 42 CFR Part 74.

(g) If the examining physician determines that alternative medical examinations to those

required by (a) of this subsection will provide at least equal assurance of detecting

medical conditions pertinent to the exposure to vinyl chloride, the employer may

accept such alternative examinations as meeting the requirements of (a) of this

subsection, if the employer obtains a statement from the examining physician setting

forth the alternative examinations and the rationale for substitution. This statement

must be available upon request for examination and copying to authorized

representatives of the director.

(11) Communication of hazards.

(a) Hazard communication-General.

(b) Chemical manufacturers, importers, distributors and employers must comply with all

requirements of the Hazard Communication Standard (HCS), WAC 296-901-140 for

vinyl chloride and polyvinyl chloride.

(c) In classifying the hazards of vinyl chloride at least the following hazards are to be

addressed: Cancer; central nervous system effects; liver effects; blood effects; and

flammability.

(d) Employers must include vinyl chloride in the hazard communication program

established to comply with the HCS, WAC 296-901-140. Employers must ensure

that each employee has access to labels on containers of vinyl chloride and to safety

data sheets, and is trained in accordance with the requirements of HCS and subsection

(9) of this section.

(12) Signs.

(a) The employers must post entrances to regulated areas with legible signs bearing the

legend:

DANGER

VINYL CHLORIDE

MAY CAUSE CANCER

AUTHORIZED PERSONNEL ONLY

(b) The employer must post signs at areas containing hazardous operations or where

emergencies currently exist. The signs must be legible and bear the legend:

DANGER

VINYL CHLORIDE

MAY CAUSE CANCER

WEAR RESPIRATORY PROTECTION AND PROTECTIVE CLOTHING IN THIS

AREA

AUTHORIZED PERSONNEL ONLY

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 7

(13) Labels.

(a) In addition to the other requirements in this section, the employer must ensure that

labels for containers of polyvinyl chloride resin waste from reactors or other waste

contaminated with vinyl chloride are legible and include the following information:

CONTAMINATED WITH VINYL CHLORIDE

MAY CAUSE CANCER

(b) No statement shall appear on or near any required sign, label, or instruction which

contradicts or detracts from the effect of any required warning, information, or

instruction.

(14) Records.

(a) All records maintained in accordance with this section must include the name and

social security number of each employee where relevant.

(b) Records of required monitoring and measuring and medical records must be provided

upon request to employees, designated representatives, and the director in accordance

with chapter 296-802 WAC. These records must be provided upon request to the

director. Authorized personnel rosters must also be provided upon request to the

director.

Monitoring and measuring records must:

(A) State the date of such monitoring and measuring and the concentrations

determined and identify the instruments and methods used;

(B) Include any additional information necessary to determine individual

employee exposures where such exposures are determined by means other

than individual monitoring of employees; and

(C) Be maintained for not less than 30 years.

Medical records must be maintained for the duration of the employment of each

employee plus 20 years, or 30 years, whichever is longer.

(c) The employer must comply with any additional requirements set forth in chapter 296-

802 WAC.

(d) Employees or their designated representatives must be provided access to examine

and copy records of required monitoring and measuring.

(e) Former employees must be provided access to examine and copy required monitoring

and measuring records reflecting their own exposures.

(f) Upon written request of any employee, a copy of the medical record of that employee

must be furnished to any physician designated by the employee.

(15) Reports.

(a) Not later than 1 month after the establishment of a regulated area, the following

information must be reported to the director. Any changes to such information must

be reported within 15 days.

Chapter 296-62 WAC Part G

General Occupational Health Standards Carcinogens (Specific)

_________________________________________________________________________________________________________

Part G, Page 8

The address and location of each establishment which has one or more

regulated areas; and

The number of employees in each regulated area during normal operations,

including maintenance.

(b) Emergencies and the facts obtainable at that time, must be reported within 24 hours to

the director. Upon request of the director, the employer must submit additional

information in writing relevant to the nature and extent of employee exposures and

measures taken to prevent future emergencies of similar nature.

(c) Within 10 working days following any monitoring and measuring which discloses

that any employee has been exposed, without regard to the use of respirators, in

excess of the permissible exposure limit, each such employee must be notified in