Practical guide

to using duplex

stainless steels

A GUIDE TO THE USE OF

NICKEL-CONTAINING ALLOYS

N

O

10044

KNOWLEDGE

FOR A BRIGHTER

FUTURE

2

Practical guide to using duplex stainless steels

2

Practical guide to using

duplex stainless steels

(10044)

A GUIDE TO THE USE OF NICKEL-CONTAINING ALLOYS

Second Edition

Published 2020

The material presented in this publication has been prepared for the

general information of the reader and should not be used or relied

on for specic applications without rst securing competent advice.

The Nickel Institute, its members, staff and consultants do not

represent or warrant its suitability for any general or specic use and

assume no liability or responsibility of any kind in connection with

the information herein.

Second Edition 2020 by Dr. James Fritz, edited by Geir Moe.

This edition is a major update of the rst edition from 1990.

Cover photo: 2205 Duplex stainless steel tube-to-tubesheet weld,

electrolytically etched with NaOH.

3

Nickel Institute

Introduction

While duplex is a frequently used term with many different

meanings, the term duplex stainless steel has come to mean

a grade whose annealed structure is typically about equal

parts austenite and ferrite, Figure 1. Although not formally

de ned, it is generally accepted that the lesser phase will

be at least 30% by volume. For an in-depth discussion of the

microstructures of duplex stainless steels see reference (1).

Duplex stainless steels offer several advantages over the

common austenitic stainless steels. The duplex grades are:

• highly resistant to chloride stress corrosion cracking;

• about twice as strong as the common austenitic stainless

steels, which allows for weight savings by means of higher

allowable stresses and thinner material and thus cost savings;

• substantially lower in nickel content than common auste-

nitic grades, and thus are less sensitive to nickel price.

In recent years economic pressure due to the high price of

nickel and molybdenum has increased the interest in duplex

stainless steels as lower cost alternatives to austenitic stainless

steels. The duplex family of stainless steels offer a wide range

of pitting and crevice corrosion resistance from the lean duplex

grades with resistance that approaches Type 316L (S31603)

austenitic stainless steel to hyper duplex grades that are more

resistant than the 6%Mo super austenitic stainless steels.

First and second-generation duplex

stainless steels

Duplex stainless steels have been available since the 1930s.

Because of their relatively high chromium and molybdenum

contents, the rst-generation duplex stainless steels, such

as Type 329 (S32900) and Uranus 50 (S32404), have good

localised corrosion resistance. However, when welded these

grades lose the optimal balance of austenite and ferrite and

consequently, the corrosion resistance and toughness are

reduced. Although these properties can be restored by a post

weld heat treatment, most applications of rst-generation

duplex stainless steels were restricted to the annealed

condition without subsequent welding.

In the 1970s this problem was overcome through the use

of nitrogen as an alloy addition. The introduction of Argon-

Oxygen Decarburisation (AOD) technology permitted the

precise and economical control of nitrogen content in

stainless steel. Although nitrogen was initially used because

it was an inexpensive austenite former, replacing some nickel,

it was soon discovered that it had other bene ts including

improved tensile properties, rapid restoration of the desired

phase balance after welding, and increased localised corrosion

resistance.

Practical guide to using

duplex stainless steels

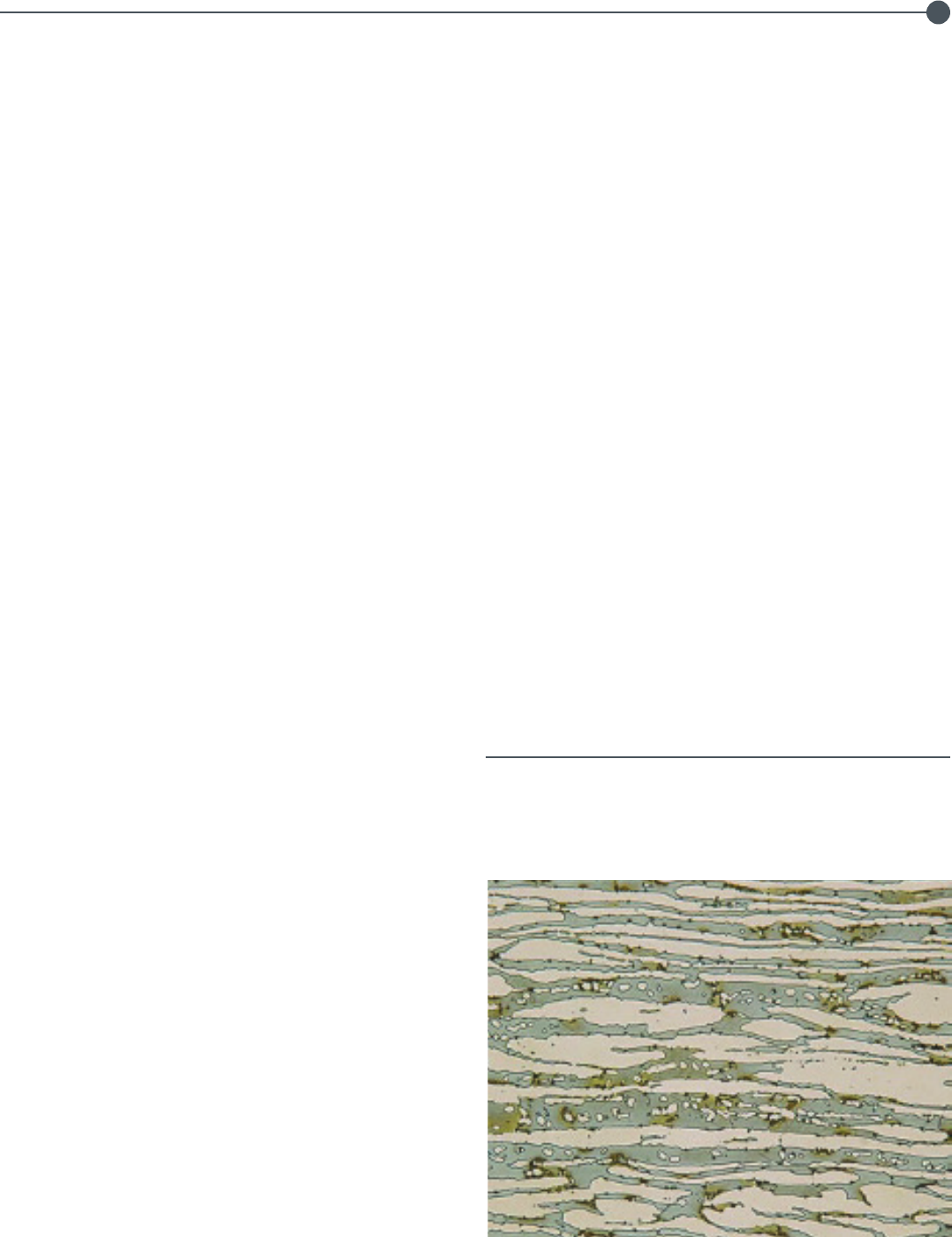

Figure 1 Wrought UR 52N+ (UNS S32520) duplex stainless steel plate

in the mill-annealed and water–quenched condition. The microstruc-

ture contains approximately equal amounts of attened islands of

austenite (light phase) and ferrite (dark phase). NaOH etchant/

Magni cation 1000X. (courtesy of Materials Technology Institute, Inc.)

4

Practical guide to using duplex stainless steels

Table 1 Nominal compositions (wt%) of wrought duplex stainless steels

UNS

designation

Common

name or type

EN Cr Mo Ni Cu Mn

A

C

A

N

A

Other PRE

B

First-generation duplex stainless steels

S31500 1.4424 18.5 2.7 4.9 - 1.2-2.0 0.03 0.05-0.10 1.7Si 27

S32404 21 2.2 6 1.4 2.0 0.04 - - 28

S32900 329

C

1.4480 26 1.5 4.5 - 1.0 0.08 - - 31

Second-generation duplex stainless steels

“Lean” duplex

S32001 1.4482 20 0.6 1.6 - 4.0-6.0 0.03 0.05-0.17 - 22

S32101 1.4162 21 0.4 1.5 0.5 4.0-6.0 0.04 0.20-0.25 - 26

S32202 1.4062 22.5 0.4 2.2 - 2.0 0.03 0.18-0.26 - 27

S32304 2304

D

1.4362 23 0.3 4.0 0.3 2.5 0.03 0.05-0.20 - 26

S82011 21 0.4 1.5 - 2.0-3.0 0.03 0.15-0.27 - 26

S82012 1.4635 19.5 0.3 1.2 - 2.0-4.0 0.05 0.16-0.26 - 25

S82013 20 - 1 0.8 2.5-3.5 0.06 0.20-0.30 - 24

S82122 21 0.6 2 1 2.0-4.0 0.03 0.15-0.20 - 25

1.4655 22.5 0.3 4.5 2 2.0 0.03 0.05-0.20 - 26

1.4669 22 0.5 2 2.2 1.0-3.0 0.045 0.12-0.20 - 26

Molybdenum-containing “lean” duplex

S32003 21.5 1.8 3.3 - 2.0 0.03 0.14-0.20 - 30

S81921 21 1.5 3 2.0-4.0 0.03 0.14-0.20 - 27

S82031 1.4637 21 1 3 2.5 0.05 0.14-0.24 - 27

S82121 21.5 0.8 3 1.0-2.5 0.035 0.15-0.25 - 27

S82441 1.4662 23.5 1.5 3.5 2.5-4.0 0.03 0.20-0.30 - 33

“Standard” duplex

S31803 2205

D

1.4462 21 2.7 5.0 - 2.0 0.03 0.08-0.20 - 31

S32205 2205

D

1.4462 22 3 5.0 - 2.0 0.03 0.14-0.20 - 35

S31200 1.4460 25 1.7 6.0 - 2.0 0.03 0.14-0.20 - 32

S32950 26.5 1.5 4.8 - 2.0 0.03 0.15-0.35 - 34

S31260 1.4481 25 3 7 0.5 1.0 0.03 0.10-0.30 0.3W 37

S32808 27 1 7 - 1.1 0.03 0.30-0.40 2.3W 39

“Super” duplex

S32506 25 3 6 - 1.0 0.03 0.08-0.20 0.15W 40

S32520 1.4507 25 4 6.5 1 1.5 0.03 0.20-0.35 - 41

S32550 255

D

1.4507 25 3.5 6 2 1.5 0.04 0.10-0.25 - 40

S32750 2507

D

1.4410 25 4 7 - 1.2 0.03 0.24-0.32 - 42

S32760 Z100

D

1.4501 25 3.5 7 0.7 1.0 0.03 0.20-0.30 0.7W 41

S32906 1.4477 28 2 6 - 0.80-1.5 0.03 0.30-0.40 - 40

S39274 25 3 7 0.5 1.0 0.03 0.24-0.32 1.8W 42

S39277 25 3.5 7 1.5 0.80 0.025 0.23-0.33 1W

Increased nitrogen content causes the ferrite-to-austenite

transition to occur at higher temperatures, allowing the

formation of an acceptable balance of austenite and ferrite

after a rapid thermal cycle such as that in the heat-affected

zone (HAZ) of a weld. This nitrogen advantage enables the

use of duplex stainless steels in the as-welded condition

and spurred the development of second-generation duplex

stainless steels. Second-generation duplex grades are best

dened by a required nitrogen addition typically in the range

of 0.15 – 0.40%.

5

Nickel Institute

“Hyper” duplex

S32707 1.4658 27 4.8 6.5 - 1.5 0.03 0.30-0.50 1.0Co 50

S33207 1.4485 30 3.5 7 - 1.5 0.03 0.40-0.60 - 52

Austenitic stainless steels

S30403 304L

C

1.4307 18 - 8 - 2.0 0.03 0.10 - 20

S31603 316L

C

1.4404 16 2 11 - 2.0 0.03 0.10 - 24

S31703 317L

C

1.4438 18 3 11 - 2.0 0.03 0.10 - 29

N08904 904L

D

1.4539 20 4.1 24 1.0 2.0 0.02 - - 34

N08367 20 6 24 - 2.0 0.03 0.18-0.25 - 43

S31254 1.4547 20 6 18 0.8 1.0 0.02 0.18-0.22 - 43

A

ASTM Specication range or maximum if single number

B

Pitting Resistance Equivalent number calculated from PRE = %Cr + 3.3[%Mo + 0.5(%W)] +16(%N) and the nominal compositions

C

A grade designation originally assigned by American Iron and Steel Institute (AISI)

D

Common name, not a trademark, widely used, not associated with any one producer

Categories of duplex stainless steel

Wrought duplex stainless steels

Table 1 lists the compositions of some of the more common

wrought duplex stainless steels with some selected austenitic

stainless steels included for comparison. Also tabulated in

this table are the Pitting Resistance Equivalent numbers (PRE)

calculated from the following expression and each alloy’s

nominal composition:

PRE = % Cr + 3.3[%Mo + 0.5(W)] + 16[%N]

This empirical relationship, derived by statistical regression

applied to a large volume of corrosion test results, provides

a relative ranking of a stainless steel’s pitting and crevice

corrosion resistance based on the levels of Cr, Mo, W, and

N present in the alloy. The names, trademarks, registered

trademarks and the associated producers for common

wrought duplex stainless steels are listed in Table 2.

The second-generation grades are loosely divided into

categories depending on the level of alloying. Lean duplex

stainless steels are characterised by having relatively low

levels of nickel and/or molybdenum. To compensate for the

reduced Ni, which is a strong austenite former, the N and

Mn levels are increased to provide an acceptable balance of

austenite and ferrite. As a group, the lean duplex stainless

steels have a very good combination of strength and corrosion

resistance and are ideally suited for structural applications,

tank construction, and service environments that require

resistance to chloride stress corrosion cracking.

The standard duplex stainless steel grades typically contain

22 to 25% Cr and 2 to 3% molybdenum. Grades in this cate-

gory are used widely across all industry sectors. Type 2205

(S32205) duplex stainless steel has evolved into the work-

horse grade and is by far the most widely used of all sec-

ond-generation duplex stainless steels. With many producers

in Europe, North America, and Asia, it is readily available in

almost all product forms.

There currently are two variations of the 2205 grade listed

in ASTM A240, S31803 and S32205. The S32205 grade has

slightly higher levels of Cr, Mo, and N, essentially the upper

half of the ranges permitted for these elements in S31803. It

was developed to address the potential loss of corrosion and

toughness properties in the HAZ of fabrication welds produced

in S31803. It is recommended that users specify the S32205

grade and fortunately it is by far the most commonly available.

If product specications mandate the use of the S31803 desig-

nation, users should require that all S31803 products have

a composition that also meets requirements for the S32205

designation to obtain the expected consistency of properties.

The super duplex stainless steels typically have levels of Cr,

Mo, and N (and W when used) sufcient to provide a PRE

number that is approximately 40 or higher. These grades are

roughly equal to the 6%Mo super austenitic grades in their

resistance to localised chloride attack and they are often used

for applications that involve seawater exposure, chemical

process, pollution control, acid leach mining and other

industries with arduous environments.

The S32707 and S33207 hyper duplex stainless steels are more

highly alloyed than super duplex and are designed for aggres-

6

Practical guide to using duplex stainless steels

Table 2 Common names, trademarks, registered trademarks, and

associated stainless steel producers of duplex stainless steel

Producer Names, trademarks &

registered trademarks

UNS

designation

AK Steel Nitronic® 19D* S32001

ArcelorMittal - Industeel UR 2202 S32202

ArcelorMittal - Industeel UR 35N S32304

ArcelorMittal - Industeel UR 45N S31803

ArcelorMittal - Industeel UR 45N+ S32205

ArcelorMittal - Industeel UR 45NMo S32205

ArcelorMittal - Industeel UR 47N S32750

ArcelorMittal - Industeel UR 52N S32550

ArcelorMittal - Industeel UR 52N+ S32520

ArcelorMittal - Industeel UR 76N S32760

ATI Allegheny Ludlum AL 2003™ S32003

ATI Allegheny Ludlum AL 2205™ S32205

Carpenter Technology 7-Mo PLUS® S32950

Langley Alloys Ferralium® 255 S32550

Outokumpu LDX 2101® S32101

Outokumpu 2205 Code Plus Two® S32205

Outokumpu SAF 2507 S32750

Sandvik 3RE60 S31500

Sandvik SAF 2304 S32304

Sandvik SAF 2205 S32205

Sandvik SAF 2507 S32750

Sandvik SAF 2707 HD S32707

Sandvik SAF 3207 HD S33207

Sumitomo Metal

Technology, Inc.

DP-3 S31260

Sumitomo Metal

Technology, Inc.

DP-3W S39274

Sumitomo Metal

Technology, Inc.

DP-28W S32808

Thyssen Krupp Nirosta® 4462 S32205

Thyssen Krupp Nirosta® 4501 S32760

Rolled Alloys Zeron® 100 S32760

sive acidic and chloride-containing environments. Because

these grades are more highly alloyed than the super duplex

stainless steels, the term hyper duplex stainless steel is some-

times used to describe this category of alloy and to distinguish

it from the super duplex grades. The hyper grades are currently

only available as seamless pipe and tubing because of the dif-

culty in heat treatment and avoiding deleterious intermetallic

particles, and it remains to be seen if other product forms and

other similar competitive grades will be developed.

Cast duplex stainless steels

First generation cast duplex stainless steels such as

CD4MCu (J93370) have been used for more than fty years.

There are now various second-generation cast grades,

such as CD4MCuN (J93372) and CD3MWCuN (J93380), that

offer improved weldability and corrosion resistance in

comparison to the lower nitrogen containing rst generation

grades, Table 3. As shown in Figure 2, the solution annealed

microstructure of cast duplex stainless steel also contains

approximately equal amounts of austenite and ferrite.

Table 3 Designations and specications for duplex stainless steel

castings

ACI or other names UNS number ASTM PREN

A

CD4MCu, 1A J93370 A890 31

CD4MCuN, 1B J93372 A890/A995 34

CD3MCuN J93373 A890 40

CE8MN, 2A J93345 A890/A995 37

CD6MN, 3A J93371 A890/A995 35

CD3MN, 4A J92205 A890/A995 35

CE3MN, 5A J93404 A890/A995 41

CD3MWCuN, 6A J93380 A890/A995 41

A

Pitting Resistance Equivalent number calculated from

PRE = %Cr + 3.3[%Mo + 0.5(%W)] +16(%N) and the nominal

compositions

The second-generation cast duplex stainless steels provide

good corrosion resistance, excellent resistance to stress

corrosion cracking, and improved strength over the cast

300-series austenitic stainless steels. The ferrite portion

of the microstructure has a high solubility for sulphur

and phosphorus so their propensity toward solidication

cracking is much lower than austenitic stainless steel

castings of similar corrosion resistance. Duplex stainless

steel castings have been used extensively by pump and

valve industries supplying products in to a wide range of

industrial applications.

Mechanical and physical properties

Duplex stainless steels characteristically are stronger than either

of their two phases considered separately. The duplex grades

7

Nickel Institute

have yield strengths twice those of the common austenitic

grades while retaining good ductility, Table 4. In the annealed

condition, the duplex grades have outstanding toughness

and with the second-generation duplex grades, it is possible

to retain toughness and corrosion resistance after welding.

The high strength of these steels is re ected in a correspond-

ingly high fatigue strength and these steels have a long

history in rotating equipment applications. Their behavior in

fatigue is like that of a ferritic steel in that they exhibit a xed

fatigue limit. Similarly, it has been found that fatigue design

rules for structural steels can be applied to duplex stainless

steels of the same strength level.

The physical properties such as coef cient of thermal

expansion and the heat-transfer characteristics of the duplex

stainless steels are intermediate to those of the ferritic and

the austenitic stainless steels.

Corrosion resistance

Pitting and crevice corrosion

Duplex stainless steels comprise a family of grades with a

wide range of corrosion resistance. They typically have higher

chromium contents than the standard austenitic grades and

have a molybdenum content that can vary from a fraction

of a percent for some of the lean grades to greater than

6.5 % for the S32707 hyper grade. As demonstrated by the

critical pitting and crevice corrosion temperatures presented

in Figures 3 and 4, the resistance of duplex stainless steels

to localised chloride attack covers a very wide range and is

proportional to the PRE number of the speci c grade.

For the lower range of corrosion resistance there are the

lean duplex grades such as S32001, S32101, and S32202

which have a pitting and crevice corrosion resistance that is

superior to that of Type 304L (S30403) austenitic stainless

steel and approaches that of Type 316L. In the mid-range

are the standard grades such as Type 2205, which have a

pitting resistance about equal to that of Type 904L (N08904)

austenitic stainless steel. On the high end of corrosion

resistance are the super duplex stainless steels which have a

304L 316L 317L 904L 6%Mo 2304 2003 2205 255 2507 2707

20 25 30 35 40 45

120

100

80

60

40

20

0

-20

90

70

50

30

10

0

Temperature (°C)ASTM G 150 CPT (C)

CCT (°C)

CPT (°C)

Figure 3 Critical pitting and critical crevice corrosion temperatures for

various duplex and austenitic stainless steel. Measurements

made using ASTM G48 Test methods A and B (results from

reference (2) and producers’ data).

Figure 4 Plot of the ASTM G150 critical pitting temperature vs.

the PRE number. (plotted with data from producers’ and

reference (4)).

Figure 2 Solution annealed cast CD3MWCuN (UNS J93380) micro-

structure with isolated islands of austenite (light phase) in

a ferrite matrix (dark phase). NaOH etchant/Magni cation

400X. (courtesy of Materials Technology Institute, Inc.)

PREn = %Cr + 3.3(%Mo) + 16(%N)

2507

2205

2003

2304

2101

19D

8

Practical guide to using duplex stainless steels

Table 4 Mechanical properties of wrought duplex stainless steels based on the minimum ASTM A240 requirements

Common name

or type

UNS

number EN

0.2% Yield

strength (min.) Tensile strength (min.)

Elongation

(min.) Hardness (max.)

MPa ksi MPa ksi % Brinell Rockwell C

Duplex stainless steels

S31200 1.4460 450 65 690 100 25 293 31

S31260 485 70 690 100 20 290 -

S31803 450 65 620 90 25 293 31

S32001 450 65 620 90 25 - 25

S32003 485

A

450

B

70

65

690

655

100

95

25

25

293

293

31

31

S32101 1.4162 530

A

450

B

77

65

700

650

101

94

30

30

290

290

31

31

S32202 1.4062 450 65 650 94 30 290 31

2205 S32205 1.4462 450 65 620 90 25 293 31

2304 S32304 1.4362 400 58 600 87 25 290 32

S32506 450 65 620 90 18 302 32

S32520 1.4507 550 80 770 112 25 310 32

255 S32550 1.4507 550 80 760 110 15 302 32

2507 S32750 1.4410 550 80 795 116 15 310 32

Z100 S32760 1.4501 550 80 750 108 25 310 32

S32808 500 72 700 101 15 310 32

329 S32900 1.4480 485 70 620 90 15 269 28

S32906 650

C

550

D

94

80

800

750

116

109

25

25

310

310

32

32

S32950 485 70 690 100 15 293 32

S39274 550 80 800 116 15 310 32

S81921 450 65 620 90 25 293 31

S82011 450

B

65 655 95 30 293 31

S82012 500

A

400

B

73

58

700

650

102

94

35

35

-

293

31

-

S82013 450 65 620 90 30 293 31

S82031 500

A

400

B

73

58

700

650

102

94

35

35

-

290

31

-

S82121 450 65 650 94 25 286 30

S82122 500

E

400

F

72

58

700

600

101

87

25

30

290

290

32

32

S82441 540

C

480

D

78

70

740

680

107

99

25

25

290

290

31

31

Austenitic stainless steels

304L S30403 1.4307 170 25 485 70 40 201 92

I

316L S31603 1.4404 170 25 485 70 40 217 95

I

317L S31703 1.4438 205 30 550 75 40 217 95

I

904L N08904 1.4539 220 31 490 71 35 - 90

I

6%Mo N08367 310

G

310

H

45

45

690

655

100

95

30

30

-

241

100

I

-

6%Mo S31254 1.4547 310

G

310

H

45

45

690

655

100

95

35

35

223

223

96

I

96

I

A

For thicknesses ≤ 0.187 inches [5.00 mm]

B

For thicknesses > 0.187 inches [5.00 mm]

C

For thicknesses < 0.4 inches [10.00 mm]

D

For thicknesses ≥ 0.4 inches [10.00 mm]

E

For thicknesses ≤ 0.118 inches [3.00 mm]

F

For thicknesses > 0.118 inches [3.00 mm]

G

Sheet and Strip

H

Plate

I

Rockwell B Scale

9

Nickel Institute

pitting and crevice corrosion resistance similar to the 6% Mo

super austenitic grades and the newly developed and more

resistant hyper duplex grades, which approach the pitting

resistance of the Ni-Cr-Mo alloy, C276 (N10276).

Resistance to chemical environments

The different levels of chromium, molybdenum, and nickel in

second-generation duplex stainless steels result in different

levels of resistance to chemical environments. The corrosion

data presented in Table 5 show that depending on the specic

duplex grade and the chemical environment, duplex stainless

steels compare favourably with austenitic grades in their resist-

ance. When selecting a stainless steel for aggressive chemical

environments it is recommended that a corrosion specialist

be consulted to ensure that appropriate candidate grades are

considered. Many common industrial environments and suita-

ble grades are reviewed in item 1 of Additional Resources.

Chloride stress corrosion cracking

One of the primary reasons for using duplex stainless steels is

their excellent resistance to chloride stress corrosion cracking

(SCC). However, duplex stainless steels are not immune to

chloride SCC and sufciently high temperatures and chloride

contents can produce cracking. For example, all duplex and

austenitic stainless steels are susceptible to SCC in concen-

trated boiling magnesium chloride solutions, Figure 5. Fortu-

nately, this test is so severe that it is not representative of

most practical environments and its results are not a reliable

indication of chloride SCC susceptibility in typical heat

transfer applications with less concentrated chlorides, usually

derived from sodium chloride.

Less aggressive tests, such as immersion testing in boiling

NaCl and CaCl

2

solutions and the various “Wick Tests” with

NaCl solutions have been shown to correlate with eld

experience, though cannot be used to determine resistance

for specic applications.

2

Based on results from these tests

3

all

duplex stainless steels have a very good resistance to chloride

SCC and are comparable to alloy 20 and the 6% molybdenum

super austenitic grades. The cracking thresholds for various

Table 5 Corrosion rates in select chemical environments*

Solution,

Temperature

Corrosion rate – mpy (mm/y)

Type 304L

(S30403)

Type 316L

(S31603)

Type 317L

(S31703) (S32101) (S32003)

2205

(S32205)

255

(S32550)

2507

(S32750)

1% Hydrochloric acid,

Boiling

85

(2.28)

59.0

(1.50)

56.3

(1.43)

- 48.0

(1.22)

12.2

(0.31)

- 3

(0.076)

10% Sulfuric acid,

Boiling

662

(16.81)

635

(16.13)

294

( 7.49)

- 259

(6.57)

207

(5.26)

40

(1.02)

-

20% Phosphoric acid,

Boiling

< 1.0

(< 0.03)

0.2

(<0.01)

0.7

(0.02)

- 0.39

(0.01)

0.8

(0.02)

- -

10% Sulfamic acid,

Boiling

50

(1.3)

124

(3.16)

83.1

(2.11)

- 11.4

0.29

21.2

0.54

- -

65% Nitric acid,

Boiling

8.9

(0.23)

22.3

(0.27)

48.4

(1.23)

2.7

(0.07)

30.7

(0.78)

20.6

(0.52)

16

(0.41)

16

(0.41)

20% Acetic acid,

Boiling

0.1

(0.003)

0.12

(0.003)

0.48

(0.012)

- 0.00

(0.000)

0.1

0.002

-

80% Acetic acid,

Boiling

- - - 0.08

(0.002)

- 0.1

(0.003)

<0.1

(<0.003)

0.8

(0.020)

45% Formic acid,

Boiling

- 23.4

(0.59)

18.3

(0.46)

15.0

(0.38)

0.5

(0.01)

- -

10% Oxalic acid,

Boiling

- 48.4

(1.23)

46.8

(1.19)

62.2

(1.58)

7.1

(0.18)

5.1

(0.13)

- -

50% Sodium hydroxide,

Boiling

71

(1.80)

77.6

(1.97)

32.8

(0.83)

- - 23.9

(0.61)

7.6

(0.05)

-

* Data from producers and MTI Publication No. 47, Corrosion Testing of Iron- and Nickel-Based Alloys

10

Practical guide to using duplex stainless steels

duplex stainless steels under fully immersed conditions in

neutral salt solutions are shown in Figure 6.

Metallurgy of duplex stainless steels

Understanding the metallurgy of the duplex grades is

necessary to understand the welding practices required to

ensure tough and corrosion-resistant fabrications. In order

to maintain acceptable corrosion resistance and toughness,

a desirable austenite–ferrite balance must be achieved, and

undesirable secondary phases must be avoided. Detrimental

secondary phases include intermetallic compounds such

as sigma and chi phase, undesirable carbide and nitride

formation, and precipitation of alpha prime. The composition

of duplex stainless steels and their processing, including

fabrication practice, must ensure adequate formation of

austenite to achieve a desirable austenite-ferrite balance and

avoid the formation of undesirable secondary phases.

Austenite/ferrite balance

As shown in the phase diagram in Figure 7, duplex stainless

steels solidify as 100% ferrite (a) and upon subsequent

cooling will reach a temperature where some of the ferrite

transforms to austenite (g). The temperature for the a to g

transition will depend on the alloy composition and typically

occurs in the range of 1200 to 1400 °C (2200 to 2550 °F). As

the temperature drops below the a to g transition temperature

there is an increase in the equilibrium amount of austenite

down to about 1000 °C (1832 °F). Below this temperature

there is little change in the equilibrium austenite-ferrite

balance.

If a duplex grade is cooled too rapidly, a condition that can

occur with low heat input welds on large pieces, there may

be insufcient time for the austenite to form resulting in

a structure that is enriched in ferrite. Figure 7 shows that

increased nitrogen content moves the a to g transition to

higher temperatures where the rate of transition is faster

904L

Sanicro 28

Figure 5 SEM micrograph showing cracking on S32750 specimens

after 24 hours in 45% MgCl

2

at 155°C

Figure 6 The chloride SCC threshold for various duplex and select

austenitic stainless steels in neutral chloride solutions.

(Courtesy of Sandvik)

Figure 7 Nickel - Chromium phase diagram for a 68% iron duplex

stainless steel, showing the inuence of increased nitrogen

content on the ferrite to austenite transition temperature.

(from reference 4)

20 µgMAG = 1.00 K X

EHT = 20.00kV

300

250

200

150

100

50

0

1400

1200

1000

800

(570)

(480)

(390)

(300)

(210)

(120)

(32)

(2552)

(2192)

(1832)

(1472)

Temperature °C (°F)

Temperature °C (°F)

0.0001 0.001 0.01 0.1 1 10

C?, weight %

%Ni 0 5 10 15

%Cr 30 25 20 15

SAF 2205

SAF 2507

No cracking

L + a

a

L

L + g + a

g + a

L + g

[

N

]

g

No SCC

SAF 2304

AISI 304/304L

AISI 316/316L

11

Nickel Institute

making it more likely to achieve an acceptable austenite-

ferrite balance. With second-generation duplex stainless

steels and properly qualied fabrication procedures, the

problem of too much ferrite can usually be avoided. Duplex

welding ller metals are over-alloyed with nickel to promote

austenite formation during cooling.

The increased level of ferrite that occurs upon heating to high

temperatures can be useful in hot rolling or forging where

the weak ferrite phase facilitates production. If the steel cools

sufciently during hot rolling so that a substantial amount of

austenite forms, further deformation can produce cracking,

sometimes very serious, because of the mismatch in high-

temperature strengths of the austenite and ferrite phases.

If ease of production were the only consideration, then

the duplex grades would be low in nitrogen and balanced

to ensure that the steel remains ferritic during hot rolling.

However, the interests of the fabricator and the user are

opposite those of the producer in that the user wants rapid

austenite formation to ensure toughness and restore corrosion

resistance. If the fabricator welds a low-nitrogen duplex grade

with a rapid quench of the HAZ (following what would be a

good practice for austenitic stainless steel grades), then it is

possible for this region to be excessively ferritic and lacking in

toughness and corrosion resistance.

Although there is no single dened limit on ferrite content,

any level greater than approximately 70% (ISO 17781) would

be considered unacceptable for most applications. A more

restrictive limit for ferrite content should be imposed by the

user when qualifying weld procedures in critical applications,

especially those with substantial safety risks, those involving

hydrogen sulphide and those exposed to low operating

temperatures. For guidance on the measurement of the ferrite

content of duplex stainless steels see reference (6).

Undesirable secondary phases

A potentially more serious problem, particularly because of its

inuence on toughness and corrosion properties, is the effect

of temperature excursions into a range where undesirable

secondary phases can form. The specic undesirable phases

and the critical temperature range for their formation will

depend on the duplex alloy. Fabrication processes such

as heat treating, welding, and hot working must consider

the total time at temperature, as each cycle through the

precipitation temperature range is cumulative, in order to

avoid the loss of corrosion resistance and toughness.

The primary concern for the standard, super, and hyper

duplex stainless steel grades is the formation of intermetallic

compounds in the temperature range of 700 to 955 °C (1300

to 1750 °F). In this range these duplex stainless steels

tend to form undesirable intermetallic compounds such as

sigma phase or chi phase, Figure 8. Often this category of

intermetallic compounds is called “sigma phase” because the

different intermetallic phases are all detrimental to toughness

and corrosion resistance, even if not precisely identied as

sigma phase. These complex compounds of iron, chromium,

and molybdenum are highly detrimental to corrosion

resistance, particularly to the resistance to localised chloride

attack, and toughness. The kinetics of sigma/chi precipitation

is greatest in the range of about 815 to 925 °C (1500 to

1700 °F). The time required to produce detrimental effects

on toughness and corrosion resistance typically depends

on the temperature and the alloy content. The increased

nitrogen content of second-generation duplex stainless steels

signicantly decreases the rate of the sigma/chi precipitation

reactions making it possible to weld these grades without loss

Figure 8 Microstructure of a UNS S32205 plate aged at 900 °C

(1650 °F) for 30 minutes showing large amount of sigma

precipitation on the austenite/ferrite grain boundaries.

NaOH etchant/Magnication 750X.

(courtesy of Materials Technology Institute)

12

Practical guide to using duplex stainless steels

of properties. However, cooling rates after heat treatment

and weld heat inputs and interpass temperatures must be

controlled to avoid problems.

As shown in Figure 9, increased chromium and molybdenum

contents will signicantly shorten the times before there is a

substantial loss of properties. For example, the super duplex

grade Type 2507 (S32750) shows a loss in properties within

a minute of exposure to temperatures in the 900 to 925 °C

(1650 to 1700 °F) range, while Type 2304 (S32304) grade will

only show a loss after about 80 minutes.

The duplex grades that are very lean in nickel and

molybdenum such as S32101, will form intermetallic

compounds but the required time in the sigma temperature

range for their formation is very long, typically about

100 hours. Because of this, sigma formation is not a big

concern with the lean duplex stainless steels. However,

these lean duplex grades are susceptible to the loss of

corrosion resistance and toughness due to carbide and

nitride precipitation in the temperature range of 600 to

825 °C (1100 to 1500 °F). As shown in Figure 9, the time-at-

temperature for a signicant loss of properties with a lean

grade such as S32101 is not much longer than that of the

standard 2205 grade and similar control of temperature

excursions must be practiced.

Once formed, these compounds can only be removed by a

full anneal with sufcient time to take the precipitates back

into solution and homogenise to prevent their reoccurrence

during cooling. Other than a full anneal above the stability

temperature for the intermetallic phases followed by rapid

cooling, no other remedy has been found to be effective.

If there is molybdenum segregation, as might remain from the

initial solidication from the ingot or in particular the centre

line of a concast slab, then it may be impossible to cool the

steel rapidly enough through the critical temperature range to

prevent the formation of intermetallic compounds. Centreline

segregation can occur, but it tends not to be a practical

problem as the segregated area is located in the middle of the

plate and is not exposed to the service environment.

Alpha prime precipitation

Alpha prime is another undesirable phase that can form in

the ferrite phase at temperatures between 315 and 525 °C

(600 and 950 °F). The presence of alpha prime will result in a

loss of ambient temperature toughness in the ferrite phase.

The loss of properties occurs most readily at a temperature

of approximately 475 °C (885 °F), Figure 9 and is known as

475/885 embrittlement. Because of the need to avoid alpha

prime precipitation many design codes limit the maximum

temperature somewhere in the range 260-315 °C (500-600 °F),

depending on the code.

Ductile-brittle transition

Duplex stainless steels have a wide range of applications

but not quite the versatility of the austenitic grades. In the

ideal duplex structure of nearly equal austenite and ferrite

phases essentially free of intermetallic and nonmetallic

compounds, the duplex grades show a gradual ductile-brittle

transition. The duplex grades are suitable for use in arctic

ambient conditions, as demonstrated by their success in many

applications on the Alaskan North Slope, but not for cryogenic

service.

Fabrication and welding

Cold forming

Forming operations on duplex stainless steels must take into

account the fact that they are about twice as strong as the com-

mon austenitic grades and will work-harden rapidly. However,

Figure 9 Isothermal precipitation diagram for various duplex stainless

steels showing the temperature exposure required for a 50%

reduction in impact toughness due to isothermal precipita-

tion of undesirable phases (from reference 6)

1100

1000

900

800

700

600

500

400

300

Temperature °C

0.01 0.1 1 10 100 1000

(36s) (6min)

Time (h)

2507

2205

S32101

2304

Intermetallic

precipitation

Carbides/

Nitrides

Alpha prime

13

Nickel Institute

because many designers take advantage of this higher strength

for cost savings through thickness reduction, the increased

resistance to forming may be offset by thinner sections.

Machining

The high strength and toughness tend to make most duplex

grades more difcult to machine than the common austenitic

stainless steels. Powerful, rigid machines with sharp tooling at

lower speeds and heavy feeds will produce good machined

parts in duplex stainless steels. One producer suggests that

for carbide tooling, speeds should be reduced from those

used for austenitic grades by 40% for roughing and about

20% for nishing.

Although most duplex stainless steel are signicantly more

difcult to machine than common austenitic grades, the

lean S32101 grade is reported to have machinability that

is superior to conventional austenitic stainless steels

8

and

this excellent machinability is independent of the type of

machining operation (milling, turning, drilling) or type of tools.

The reasons for this superior machinability are not completely

understood. A comparison of the machinability of selected

austenitic and duplex stainless steels is given in Tables 6 to 8.

Welding

These steels are readily welded by all common arc welding

processes. Ideally, the goal of welding a duplex stainless steel

is for the weld metal and HAZ to have a joint with toughness

and corrosion resistance equal to that of the base metal,

however usually, the intent is for the weld metal and HAZ

to be sufciently high enough to suit the application or meet

the fabrication specication requirements. The rst step is to

ensure that all the duplex is ordered and received with the

Table 6 Turning test results for select austenitic and duplex stainless steels

(7)

Grade

V

30

HSS

1

(mm/min)

V

30

2

(mm/min)

V

15

3

(mm/min)

304L (S30403) 215 220

316L (S31603) 210 215

(S32101) 42 230 245

2205 (S32205) 185 126

1

Uncoated HSS ALESA

2

Uncoated cemented carbide tool

3

Coated cemented carbide tool

Table 7 Drilling test results for select austenitic and duplex stainless steels

(7)

Grade

V

1000

(mm/min)

Drill length at 15 m/min

(m)

Metal removed

1

(mm

3

/min) Number of holes

2

(S32101) 38 30582 5000 250

304L (S30403) 15 1 1450 140

316L (S31603) 16 2 1450

2205 (S32205) 15 1 1450

1

V=26 m/min and F = 0.15 mm/r for S32101 and 11 m/min and 0.1 mm/r respectively for 304L, 316L, and 2205.

2

Indexable insert drilling at 210 m/min and 0.07 mm/rev.

Table 8 Milling and threading test results for select austenitic and duplex stainless steels

(7)

Grade V

5

(mm/min)

Milling, tool service life

1

(min)

Threading M6, number of holes at 15 m/min

(S32101) 295 18 3500

304L (S30403) 180 12

316L (S31603) 170 9

2205 (S32205) 115 8 446

1

At 150 m/min with Sandvik 1025 E-ML.

14

Practical guide to using duplex stainless steels

proper chemistry (i.e. nitrogen in the higher end of the range)

and in optimal heat treatment condition as shown by passing

ASTM A923 or A1084 testing requirements. (See section

Specications and Quality Control.) If the material received has

low nitrogen (but within the specication) or has small amounts

of secondary phases present, it may not be possible to weld

it and obtain satisfactory corrosion or toughness properties.

It is necessary to qualify each welding procedure to ensure

heat input is neither too low nor too high. Low heat inputs

can result in rapid cooling rates, which have the potential

of producing a phase balance in the HAZ that is too high

in ferrite. Too high of a heat input could expose the HAZ

to the critical temperature range for the specic alloy for

too long a time resulting in the precipitation of undesirable

secondary phases. Because problems with duplex stainless

steel welds reveal themselves by a loss of toughness or

corrosion resistance, it is prudent that welding procedure

qualications include a toughness test (e.g. Charpy V-notch)

at an appropriate temperature with acceptance criteria

appropriate to the application, such as described in ISO 17781.

Alternatively, because loss of corrosion resistance can be

associated with precipitation of secondary phases, a corrosion

test can also be used to evaluate weld procedures and it is not

uncommon to have welds evaluated with both a toughness

test and a corrosion test. Test methods for evaluating some

common duplex stainless steel grades are:

Standard Type of duplex

ASTM A923 / ISO 17781 Standard and superduplex

ASTM A1084 / ISO 17781 Lean

Higher nitrogen contents are extremely helpful in avoiding

excessive ferrite content, especially with lower-alloyed grades.

It is still necessary to be concerned about certain geometries,

which can result in very rapid cooling rates, such as liner

sheets installed on heavy plates or small welds on large

plates. In extreme cases a modest preheat or a controlled

interpass temperature for a multiple-pass weld will slow

the cooling rate enough to allow sufcient reformation of

austenite to produce good toughness and corrosion resistance.

The concern of too high heat input relates to the need to

minimise the accumulated total exposure time of the HAZ

in the critical temperature range. Even with a high nitrogen

level, the total time at approximately 850 °C (1550 °F)

before detrimental formation of intermetallic compounds

is as short as ve minutes for Type 2205 and only about

one minute for the higher alloyed super duplex grades.

This time must include both cooling after the nal anneal

and all subsequent fabrication. The ASTM A923, A1084

and ISO 17781 specications were developed to provide

test methods for detecting detrimental phases in duplex

stainless steels. It is recommended that the appropriate

A923, A1084 or ISO 17781 test methods be required to

qualify duplex stainless steel weld procedures.

If intermetallics form in a HAZ of a large fabrication where

post weld heat treatment is not a viable option, the only

remedy may be to cut the weld and HAZ out and start over.

Consequently, welding procedures must be qualied with

respect to maximum thermal exposure, including any repair

or rework practice. When later modications of equipment

are contemplated, it is important that total thermal history

be considered before performing additional welding.

It is common for ller metals to contain increased nickel

content to ensure that the rapidly quenched cast structure

of the weld is comparable to the base metal in toughness

and corrosion resistance. For example, the 2209 weld ller,

most commonly used with Type 2205, has about 9% nickel,

3-4% more than the base metal. Matching welding llers,

over-alloyed with nickel, are available for many duplex grades

and users are encouraged to contact the alloy producers for

recommendations for specic grades. Only a few duplex ller

metals are included in the welding standards such as AWS.

Weld metal toughness is strongly related to the welding

process. Non-ux processes providing greater toughness.

Typically, weld metal toughness as related to welding process

is as follows:

GTAW> GMAW>FCAW>SMAW>SAW

Highly basic uxes have been reported to be benecial to the

as-welded impact toughness of the duplex stainless steels.

When welding a duplex grade to carbon steel a Type 309L

ller is usually a good choice for achieving a sound weld. An

appropriate ller for joining 2205 or a super duplex grade to

an austenitic stainless steel of lower molybdenum content

would be 309LMo.

15

Nickel Institute

When installing a duplex stainless steel component in an ex-

isting austenitic stainless steel structure, consideration should

be given to the relative strengths and expansion coefcients

of the materials. The high strength of the duplex grade and

their relatively low expansion coefcients may impose high

stresses on the transition welds or the host structure.

Specications and quality control

Most duplex stainless steels grades are covered in one or

more of the many industry standards. Tables 9 and 10 lists

important ASTM standards and ASME coverage respectively,

and some relevant international standards for duplex

stainless steels are given in Table 11. Duplex stainless steels

are included in the NACE MR0175/ISO 15156-3 international

standard, which species environmental and material limits

for the use of materials in service equipment used in oil and

gas production. The duplex grades approved for use in the

MR0175/ISO 15156-3 Standard include:

• S31803 (HIP);

• any duplex stainless steel with 30 ≤ PRE number ≤ 40,

Mo ≥ 1.5%;

• any duplex stainless steel with 40 < PRE number ≤ 45; and

• where PRE number is

P R E = % C r + 3 . 3 [ % M o + 0 . 5 ( % W )] +1 6 ( % N ) .

The S32101, S32304, S32003, S32202 and S32205 duplex

stainless steels have approval in the NSF/ANSI Standard 61 for

drinking water applications and may be used for pipes, tubes,

storage tanks, and other products that come in contact with

drinking water.

Many of the duplex stainless steels now have coverage in

several API Standards:

• API 650 Welded Tanks for Oil Storage;

• API 5LC CRA Line Pipe; and

• API 938-C Use of Duplex Stainless Steels in the

Oil Rening Industry.

It is essential that duplex stainless steel mill products be

substantially free of intermetallic compounds and detrimental

carbides and nitrides so that fabrication procedures can be

designed to have the expected level of corrosion resistance

and toughness. This issue is not addressed in the ASTM and

ASME product specications. It remains possible for a duplex

stainless steel to meet all the requirements of the product

specication and still be so affected by secondary phases that

it is embrittled at low ambient temperatures or exhibits lower

than expected corrosion resistance.

Although there are some safeguards in the qualication of

fabricated structures, it is recommended that the end user

and fabricator impose additional test requirements on duplex

stainless steels to be certain that the base metal has the

expected properties and the proposed welding procedures

will not result in an unacceptable degradation of properties

before investing in the large expense of fabrication.

For some of the more widely used duplex grades there are

standard test methods for detecting the presence detrimental

secondary phases in base metal and welds.

ASTM A923 Detecting Detrimental Intermetallic Phase in

Duplex Austenitic/Ferritic Stainless Steels

ASTM A1084 Detecting Detrimental Phases in Lean

Duplex Austenitic/Ferritic Stainless Steels

ISO 17781 Test methods for quality control of

microstructure of ferritic/austenitic (duplex)

stainless steels

These standards include three test methods:

• Metallographic examination to determine whether there

is any visible evidence of undesirable secondary phases in

the microstructure.

• A Charpy V-notch impact test to detect the precipitation

of detrimental intermetallic phases. Although the impact

testing is very effective at detecting a loss of properties

due to the presence of undesirable phases, it is not easily

and cheaply performed in all circumstances and may be

sensitive to orientation and placement of the sample.

• A ferric chloride immersion corrosion test to detect the loss

of corrosion properties associated with the presence of

undesirable phases. (ASTM A1084 uses a ferric chloride/so-

dium nitrate solution.) The corrosion test methods can be

performed on various shapes and product forms and they

are regarded as very effective at detecting the presence of

detrimental phases.

In the case of grades proprietary to a single producer, it is

possible for the producer to use special quality controls

and demonstrate to the user that the mill products meet a

16

Practical guide to using duplex stainless steels

particular standard of quality. However, today there are many

nonproprietary duplex stainless steel grades that are made

by multiple producers. Because of this it is recommended

that whenever possible product be required to pass the

appropriate ASTM A923, A1084 or ISO 17781 impact test

and/or ferric chloride test. In addition, it is also prudent to

require water quenching of all products to reserve thermal

exposure time for the fabricator, and testing is recommended

for each plate or piece handled individually in heat treatment.

Applications

The large number of applications of duplex stainless steels

across many industry sectors demonstrates the utility and

versatility of these grades

9

. There are many second-generation

cast duplex stainless steels now available, which have further

increased the range of equipment fabricated from duplex

stainless steels. The high strength, resistance to chloride SCC,

other forms of SCC, increased availability, and relatively low

cost compared to austenitic grades with similar corrosion

resistance have resulted in increased use of duplex stainless

steels across all industry sectors.

The lean duplex stainless steels with their relatively high

strength and low cost make them ideal candidates for

blast walls on offshore platforms, storage tanks for mildly

corrosive liquids and structural applications, Figure 10. The

SCC resistance of the duplex grades allows their use in heat

transfer applications where Types 304L and 316L stainless

steels have been unsatisfactory. For example, some breweries

use the S32205 grade to overcome the problem of SCC of

tanks and piping handling their hot potable water. Other

applications include tubing for heat exchangers and embossed

dimple jackets used to heat and cool vessels

10

.

Transport applications include chemical tank trailers,

which used the S32205 grades to overcome the thermal

shock damage that can occur when loading hot corrosive

chemicals into austenitic stainless steels tanks

11

. The high

strength of duplex stainless steels also promises greater

safety or increased payload through reduced material

thickness. Ocean going tankers and chemical transport

barges have been built in duplex stainless steels because of

their strength and versatility in handling different chemical

cargoes

12-14

.

Due to their high strength and corrosion resistance in marine

environments, duplex stainless steels have been used in

many architectural applications, such as the Marina Bay

Bridge in Singapore, Figure 11.

There has been extensive use of duplex stainless steels in

oil and gas production equipment on land, in desert and

Figure 11 Marina Bay Bridge in Singapore constructed entirely of 2205

duplex stainless steel [Courtesy of Outokumpu Stainless AB]

Figure 10 LDX 2101 (S32101) duplex stainless steel fermentation

tank for the production of ethanol.

(Courtesy of Outokumpu)

17

Nickel Institute

arctic elds, offshore on xed platforms and FPSO’s and

subsea because of its excellent combination of strength

and resistance to the corrosive brines that occur naturally

in the products. Down-hole piping, oil-gas separators, heat

exchangers, process piping, pumps and valves have been

constructed of various second-generation duplex stainless

steels (see resource 1). Duplex stainless steel piping systems

are also used in geothermal power applications.

Desalination plants are using more duplex stainless steels

in thermal units for evaporator construction

15

and in reverse

osmosis plants, Figure 12, for high pressure piping, seawater

feed, brine reject piping, pumps, valves and energy recovery

systems

16

. In the chemical process industries, there is

growing use of duplex stainless steels for heat exchangers,

pressure vessels, tanks, columns, pumps, valves, and

shafting in a wide range of aggressive environments. The

S32205 grade and lean duplex grades have been used to

replace carbon-steel batch digesters

17

in the pulp and paper

industry, Figure 13. In this application the high strength of

the duplex stainless steel has allowed a reduction in wall

thickness of about 38%.

Figure 13 2205 batch digester for a Canadian pulp and paper mill

Figure 12 Superduplex piping in a Seawater Reverse Osmosis

desalination plant [Photo courtesy of Rolled Alloys]

18

Practical guide to using duplex stainless steels

Additional Resources

There are various resources available to assist users and

fabricators in the selection, fabrication, and use of duplex

stainless steels. The following list provides some helpful

resources:

1. R Francis, The Corrosion of Duplex Stainless Steels:

A Practical Guide for Engineers, published by NACE

International 2018.

2. Welding Duplex and Super-Duplex Stainless Steels, Nickel

Institute Reprint Series No 14 036, 1993. (see website –

nickelinstitute.org)

3. Duplex Stainless Steels Microstructure, Properties and

Application Edited by Robert N Gunn, Woodhead

Publishing Ltd, 1997.

4. J. V. Pellegrino, H. H. Stine, J. D. Fritz, and H. S. Ahluwalia,

Duplex Stainless Steel Atlas of Microstructures, Materials

Technology Institute, Inc., 2014.

5. Practical Guidelines for the Fabrication of Duplex Stainless

Steels, International Molybdenum Association, 3rd edition,

2014. (see website – www.imoa.info)

6. Welding Metallurgy and Weldability of Stainless Steels, John

C. Lippold and Damian J. Kotecki, A John Wiley & Sons,

Inc. 2005.

7. Welding of Duplex Stainless Steels, TAPPI Technical

Information Paper, TIP 0402-23, 2008.

(see website - www.tappi.org)

8. O. Jonsson, M. Liljas, and P. Stenvall, The Role of Nitrogen

in Longitudinal Welding of Tubing in Duplex Stainless Steels,

acom 2-1994, Outokumpu Stainless AB, 1994.

9. Bjorn Holmberg, How to Perform Welding in Duplex

Stainless Steels To Obtain Optimum Weld Metal Properties,

acom 3-1997, Outokumpu Stainless AB, 1997.

10. Mats Liljas, Choice of Specications and Design Codes

for Duplex Stainless Steels, acom 4-2000, Outokumpu

Stainless AB, 2000.

11. Jan Olsson, Why Clad When There Is Duplex?, acom 1-2005,

Outokumpu Stainless AB, 2005.

12. Mats Benson, Utilization of the Material Strength for Lower

Weight and Cost with LDX 2101® acom 3-2005, Outokumpu

Stainless AB, 2005.

13. Castings Stainless Steel and Nickel-Base, Nickel Institute,

Reference Book Series No 11 022.

14. Briony Holmes, Guidelines for Measuring the Amount of

Ferrite in Duplex Stainless Steels, Materials Technology

Institute, Inc., 2018.

19

Nickel Institute

References

1. J. V. Pellegrino, H. H. Stine, J. D. Fritz, and H. S. Ahluwalia,

Duplex Stainless Steel Atlas of Microstructures, Materials

Technology Institute, Inc., 2014.

2. D R McIntyre and R Francis (Eds), Environmental Cracking,

published by MTI, 2016.

3. High-Performance Stainless Steels, No. 11 021, Nickel

Institute, 2000

4. J. D. Fritz, B. W. Parks, J. F. Grubb, and C. P. Stinner,

The Use of Electrochemical Critical Pitting Temperature

Measurements for Evaluating Stainless Steels, Stainless

Steel World 2001, Paper P10148, 2001.

5. Practical Guidelines for The Fabrication of Duplex Stainless

Steels, International Molybdenum Association, 3rd edition,

2014.

6. Briony Holmes, Guidelines for Measuring the Amount of

Ferrite In Duplex Stainless Steels, Materials Technology

Institute, Inc., 2018.

7. Outokumpu product literature.

8. C. Bergquist and J. Olsson, LDX 2101®, a New Stainless

Steel with Excellent Machining Properties, acom 4-2006,

Outokumpu.

9. Jan Olson and Marie Louise Falkland Versatility of Duplex,

Stainless Steel World Duplex America 2000 Conference

Houston Paper - DA2-011.

10. B. J. Uhlenkamp and J. D. Fritz, The Use of a Lean Duplex

Stainless Steel, UNS S32101, for Thermal Dimple Jackets on

Vessels for High Purity Applications, NACE International,

Corrosion 2007, Paper No. 07218, 2007.

11. Richard R, Staebler, Comparison of Duplex to Austenitic

Stainless Steels For DOT 407 and 412 Cargo Tanks In Liquid

Chemical Service, NACE International, Corrosion 1998

Conference & Expo, Paper No. 628, 1998.

12. Jacques Charles and Bruno Vincent, Duplex Stainless Steels

for Chemical Tankers, 5th World Conference – Duplex

Stainless Steels 97, Paper D97-018, 1997.

13. Thomas L. Ladwein, Volker Groß, Herbert Heuser, and

Christian Koerber, Use of 22% Chromium Duplex Stainless

Steel for Chemical Cargo Vessels and Tank Trailers, 5th

World Conference – Duplex Stainless Steels 97, Paper

D97-037, 1997

14. Bela Lefer, Hans Groth, and Arne Bergquist, Advantages

and Limitations of 2205 and Other Duplex Stainless Steels

for the Transport of Chemicals, 5th World Conference –

Duplex Stainless Steels 97, Paper D97-018, 1997.

15. Jan Olsson and Viktor Jagerstrom, MSF Chambers of Solid

Duplex Stainless Steel, IDA World Congress on Desalination

and Water Reuse, Paradise Island, Bahamas, 2003.

16. Jan Olsson, and Kenan Cosic, Stainless Steels for SWRO

Plants High-Pressure Piping, Properties, and Experience,

IDA World Congress on Desalination and Water Reuse,

Paradise Island, Bahamas, 2003.

17. Johan Nordstrom, Digesters and Pulp Storage Towers of

Duplex Stainless Steels – Saving Weight and Costs, acom

3-1994, Outokumpu Stainless AB, 1994.

20

Practical guide to using duplex stainless steels

21

Nickel Institute