Thomas Jefferson University Thomas Jefferson University

Jefferson Digital Commons Jefferson Digital Commons

College of Humanities and Sciences Faculty

Papers

Jefferson College of Humanities and Sciences

12-21-2017

The Effect of Time, Roasting Temperature, and Grind Size on The Effect of Time, Roasting Temperature, and Grind Size on

Caffeine and Chlorogenic Acid Concentrations in Cold Brew Caffeine and Chlorogenic Acid Concentrations in Cold Brew

Coffee Coffee

Niny Z. Rao

Thomas Jefferson University

Megan Fuller

Thomas Jefferson University

Follow this and additional works at: https://jdc.jefferson.edu/jchsfp

Part of the Chemistry Commons

Let us know how access to this document bene;ts you

Recommended Citation Recommended Citation

Rao, Niny Z. and Fuller, Megan, "The Effect of Time, Roasting Temperature, and Grind Size on Caffeine and

Chlorogenic Acid Concentrations in Cold Brew Coffee" (2017).

College of Humanities and Sciences

Faculty Papers.

Paper 2.

https://jdc.jefferson.edu/jchsfp/2

This Article is brought to you for free and open access by the Jefferson Digital Commons. The Jefferson Digital

Commons is a service of Thomas Jefferson University's Center for Teaching and Learning (CTL). The Commons is

a showcase for Jefferson books and journals, peer-reviewed scholarly publications, unique historical collections

from the University archives, and teaching tools. The Jefferson Digital Commons allows researchers and interested

readers anywhere in the world to learn about and keep up to date with Jefferson scholarship. This article has been

accepted for inclusion in College of Humanities and Sciences Faculty Papers by an authorized administrator of the

Jefferson Digital Commons. For more information, please contact: [email protected].

1

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

www.nature.com/scientificreports

The Eect of Time, Roasting

Temperature, and Grind Size on

Caeine and Chlorogenic Acid

Concentrations in Cold Brew Coee

Megan Fuller & Niny Z. Rao

The extraction kinetics and equilibrium concentrations of caeine and 3-chlorogenic acid (3-CGA) in cold

brew coee were investigated by brewing four coee samples (dark roast/medium grind, dark roast/

coarse grind, medium roast/medium grind, medium roast/coarse grind) using cold and hot methods.

3-CGA and caeine were found at higher concentrations in cold brew coee made with medium roast

coees, rather than dark roast. The grind size did not impact 3-CGA and caeine concentrations of

cold brew samples signicantly, indicating that the rate determining step in extraction for these

compounds did not depend on surface area. Caeine concentrations in cold brew coarse grind samples

were substantially higher than their hot brew counterparts. 3-CGA concentrations and pH were

comparable between cold and hot brews. This work suggests that the dierence in acidity of cold brew

coee is likely not due to 3-CGA or caeine concentrations considering that most acids in coee are

highly soluble and extract quickly. It was determined that caeine and 3-CGA concentrations reached

equilibrium according to rst order kinetics between 6 and 7 hours in all cold brew samples instead of 10

to 24 hours outlined in typical cold brew methods.

In 2015, domestic coee consumption in the United States reached an estimated 1.4 billion kg/year, making

it the second largest coee market in the world aer the European Union

1

. e majority of coee consumed

in the United States is prepared through various hot brewing methods, whereby the hot water solubilizes and

extracts numerous organic compounds from the roasted coee grounds. However, cold brew coee preparation

techniques have grown in popularity, both in at-home and consumer (or ready-to-drink, RTD) markets. Market

researcher, StudyLogic, estimates that coee shop sales of hot coee fell 3% in 2016, while cold brewed coee

sales were up nearly 80% over the previous year’s record

2

. Roast Magazine reports a 460% increase in retail sales

of refrigerated cold brew coee from 2015 to 2017, generating $38 million in 2017 alone

3

. In an eort to capitalize

on this rapidly growing market, Dunkin’ Donuts, Starbucks, and other commercial coee vendors have invested

in RTD cold brew coee beverages and are suggesting that colder, slower brewing processes alter avor, aroma,

and bioactive compounds

4

. Starbucks markets that cold brew coee is sweeter, smoother, with a more full-bodied

avor than conventionally brewed coee

5

. Dunkin’ Donuts claims that, “cold brew is less acidic and naturally

sweeter than regular coee, so it can easily be consumed black”

6

.

Cold brew coee, not to be confused with iced coee (which is hot brewed coee served over ice), is prepared

at room temperature (20 to 25 °C or colder) over a longer time period than traditional hot brewing methods,

typically steeping times range from 8 to 24 hours

7–10

. Brewing coee is an extraction process dependent on a

multitude of variables such as water volume, water temperature, diameter of the coee grind particles, the poros-

ity of the coee grind matrix, the pore network between coee grind particles, and brewing time. Temperature

oen signicantly inuences compounds aqueous solubility, so dierences in brewing temperatures may result in

signicantly dierent compositions in hot brew and cold brew coees. Additionally, the longer brewing times of

cold brew coee may aect the nal composition of cold brew coee if the diusion of the compounds across the

grind matrix is a kinetically limiting phenomenon.

An extensive body of literature exists detailing the chemistry of hot brewed coee, including quantifying the

caeine concentration as a function of hot water brewing method

11–14

. Bioactive chemicals such as chlorogenic

Department of Chemistry and Biochemistry, Thomas Jeerson University, East Falls Campus, Philadelphia, PA,

19144, USA. Correspondence and requests for materials should be addressed to M.F. (email: [email protected])

Received: 26 September 2017

Accepted: 7 December 2017

Published: xx xx xxxx

OPEN

www.nature.com/scientificreports/

2

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

acids, caeine, and other dietary phenolic compounds that include caeoylquinic acids, dicaeoylquinic acids,

and feruloylquinic acids

15

are abundant in coee. ese chlorogenic acid compounds convey bitterness to coee

11

and are known to be active antioxidants that may cause health benets in coee drinkers

16–18

. e presence of

these bioactive compounds in the complex chemical composition of coee extracts have prompted numerous epi-

demiological studies to ascertain the degree and manner in which coee confers health risks and/or benets

19

to

the drinker. Researchers have observed both U-shaped

19–21

and J-shaped

22

associations between coee consump-

tion and risks of cardiovascular diseases. Inverse relationships have been found with coee consumption and

total mortality

23,24

, depression

25

, diabetes mellitus

26,27

and certain types of cancers

28–30

. Work by Bakuradze, et al.

showed compounds present in coee roast products, notably 5-caeoylquinic acid and caeic acid demonstrated

direct antioxidant activity in HT-29 (human colon) cells

31

. A recent review by Naveed et al. further highlighted

the therapeutic roles of chlorogenic acids in human health and called for further research in the area

32

. ese

studies oen focus on analysis of green coee beans, hot brewed coee consumption, or make no distinction

to the brewing method used. Research in hot brew coees show that both roasting temperature

33,34

and grind

size

35,36

aect the extraction kinetics and maximum extractable concentration of soluble compounds from coee

grinds, specically chlorogenic acids

37–40

. Increases in roasting temperatures correlate to a decrease in extractable

chlorogenic acid concentrations and to an increase in caeine concentrations

33

. However, because of the potential

chemical dierences between hot and cold brew coee, it is unknown if the new popular drink will convey similar

benets to its hot brew counterpart.

Despite the increasing popularity of cold brew coee, there is currently very little research published on the

chemistry or associated health risks and/or benets of cold brew coee. An exhaustive literature search revealed

very limited publications analyzing cold brew coee. In 2014, Kim and Kim reported that the avor of cold brew

coee may be more appealing to the Korean coee consumers aer 18 hours brewing time

41

. In 2017, Lane et

al. reported that caeine concentrations of commercially brewed cold brew coee was ~207 mg per 12 . oz

42

.

A third study by Shin in 2017 reported that the polysaccharides isolated from cold brew coee “may potentially

enhance macrophage functions and the intestinal immune system”

43

. To date, these publications represent the

majority of published research available on cold brew coee. Commercial vendors’ claims of lower acidity and

other taste and chemical attributes have yet to be veried by unbiased research.

Given cold brew coee’s signicant growth in the coee market and the potential importance of coee’s bio-

active compounds on human health, this research investigated the role of cold brewing methods on the kinetics

and equilibrium conditions of two compounds of interest: caeine and 3-chlorogenic acid (3-CGA). e pH of all

coees produced in this research was also measured to determine if cold brew coee does results in a less acidic

coee beverage. is work studied the extraction kinetics of caeine and 3-chlorogenic for both cold and hot

brew methods using single origin Arabica beans grown in the Kona Region of Hawai’i in order to determine the

eect water temperature and brewing time on the extraction kinetics and maximum equilibrium concentration

of these two bioactive compounds. Brewing methods employed in this work mimicked standard home-brewing

conditions to inform what, if any, dierences consumers can expect between hot and cold brew coees.

Results

Kinetics of cold brew coee extraction. Four coee samples were used in this study. See Table1 for

grind size distribution and roasting temperature characteristics for each of the samples.

e grain size distributions of the four samples show that the “medium” grind coees had wider particle

distributions, both containing about 5% of particles, by mass, that are larger than 3350 µm. e “coarse” grind

coees showed no 3350 µm portion, and have a narrower particle distribution with more than 70% of particles, by

mass, being retained on the 841 µm sieve. Coee beans are naturally porous. e pore space within each grain of

coee is considered the intragranular pores. e space between grains of coee is referred to as the intergranular

pores. Earlier studies found that particle distribution was vitally important to coee extraction, aecting both the

diusion of compounds through intragranular pores within grinds, as well as the uid ow between the grinds

(through the intergranular pore network)

14,44,45

. e importance of both intragranular and intergranular pore

space will be discussed further with respect to diusion limiting processes of compound extraction kinetics.

Sample Name (Roast - Grind) Grind Size (% by mass) Roasting Temperature

Medium - Medium

3350 µm - 5.7%

841 µm - 26.2%

400 µm - 53.3%

149 µm - 14.8%

215 –217 °C

Medium - Coarse

3350 µm - 0%

841 µm - 70.6%

400 µm - 23.1%

149 µm - 6.3%

215 –217 °C

Dark - Medium

3350 µm - 5.2%

841 µm -38.1%

400 µm - 45.4%

149 µm - 11.3%

223 –225 °C

Dark - Coarse

3350 µm - 0%

841 µm - 77.8%

400 µm - 17.5%

149 µm - 4.3%

223 –225 °C

Table 1. Summary of grind size distribution by percent mass (100.0 g of grinds used in each analysis) and

roasting temperature, as reported by the coee vendor.

www.nature.com/scientificreports/

3

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

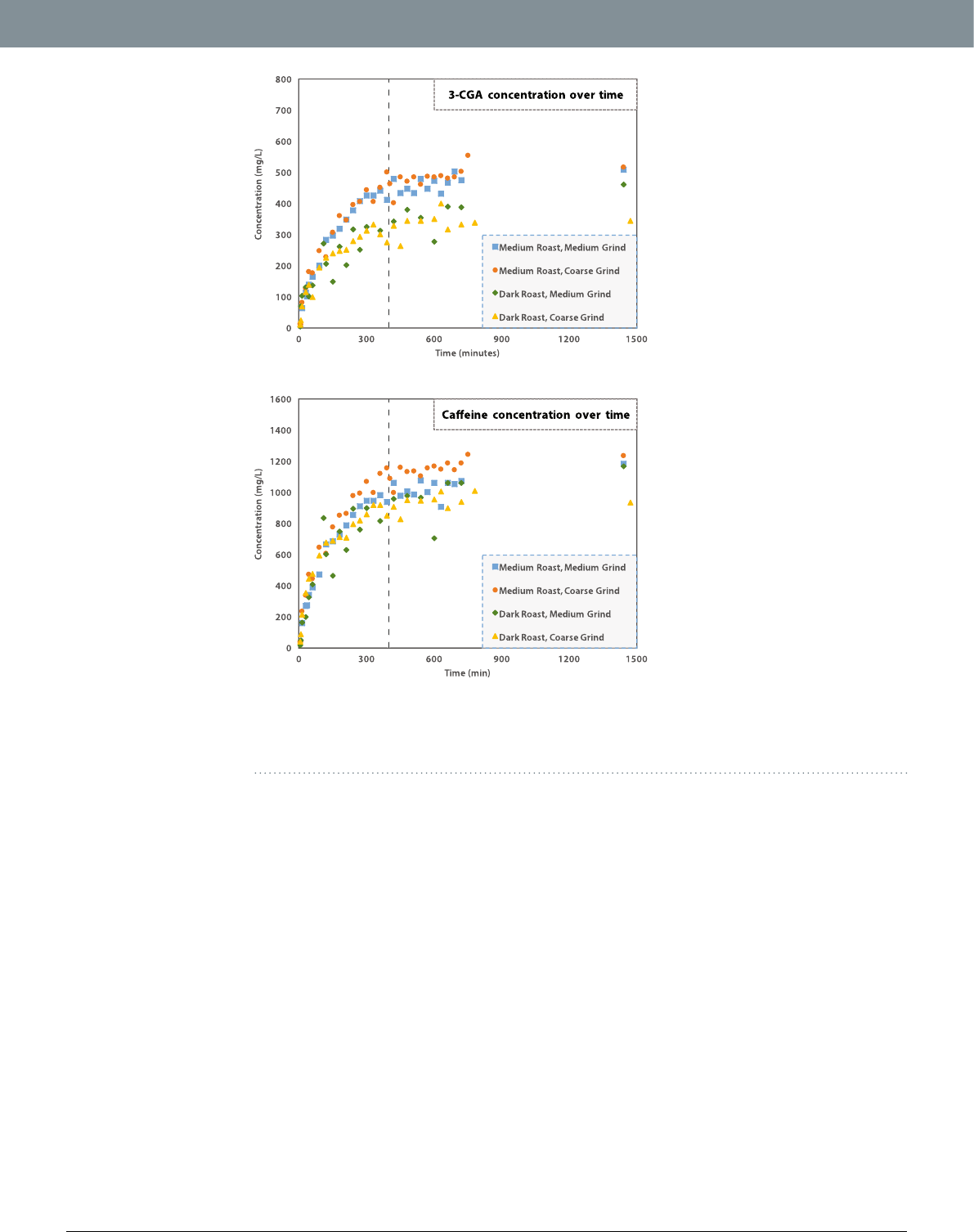

3-CGA. e compound, 3-CGA is freely soluble in water at room temperature

46

. Initial 3-CGA concentration

increased rapidly over the rst 180 minutes and slowed until reaching equilibrium at approximately 400 minutes

for all coee roasts and grinds (see Fig.1). Moroney et al.

45

attributed the initial fast extraction of soluble coee

compounds to the extraction of compounds from the surface and near-surface volume of the solid coee grind

matrix. e slower, longer time-scale extraction of additional CGA concentration, post 180 minutes, is likely due

to the mass transfer of the compound through intra-grain pores into intergrain pores, and ultimately into the bulk

liquid phase. e data collected in this current work follows the Spiro and Selwood

36

model well and suggests that

cold brew processes of 3-CGA extraction are governed by rst-order kinetics. A sample kinetic plot of ln (C

∞

/

[C

∞

− C]) for 3-CGA versus time is shown in Fig.2 where C

∞

is the equilibrium concentration of 3-CGA and C is

the concentration of 3-CGA at time t. Several sources

7–10

providing brewing instructions for cold brew coee rec-

ommend prolonged brewing times upwards of 12 to 24 hours. Any water/grind interaction longer than 400 min-

utes (6.7 hours) did not result in additional signicant extraction of 3-CGA. e mean concentrations of 3-CGA

at 400 and 1400 minutes were within one standard deviation of each other (see Table1). ese data suggest

3-CGA concentrations are inuenced by roasting temperature, but not grind size. Blumberg et al.

11

determined

that increased roasting temperatures resulted in degradation of chlorogenic acid precursors and lower extractable

total chlorogenic acid concentrations. e same study also observed that chlorogenic acids extracted quickly from

coee grinds, while 4-vinylcatechol oligomers showed strong retention to the coee grinds

11

. e longer steeping

times associated with cold brew coee may result in increased extraction of these catechol oligomers, which are

characterized by harsh bitter-tasting properties. Over-brewing cold brew coee may result in unpalatable extracts

due to these and other relatively slow-extracting compounds.

Caeine. Caeine, unlike 3-CGA, has a limited solubility at room temperature of 16 mg/mL

46

. However, all

four coees analyzed showed comparable extraction kinetics to those of 3-CGA. In all coees sampled, fast ini-

tial extraction was seen over the rst 180 minutes, with a slower rate of extraction aer 180 minutes. Similar to

Figure 1. Concentration of 3-CGA (top) and caeine (bottom) over time for (■) medium roast - medium

grind; (

●) medium roast - coarse grind; (

) dark roast – medium grind, (▲) dark roast - coarse grind. e

vertical line at 400 minutes represents the establishment of steady-state concentration for both 3-CGA and

caeine extractions.

www.nature.com/scientificreports/

4

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

3-CGA, caeine also reaches nearly steady-state concentrations aer 400 minutes (see Fig.1). As with 3-CGA,

all samples followed a rst-order kinetic model. Spiro and Selwood

36

oered a thorough mathematical model for

the kinetics of caeine extraction at room temperature, and found that the diusion of caeine through the intra-

granular pore space to be the rate limiting step in the extraction process. is analysis concluded that extraction

times greater than 400 minutes do little to increase the caeine concentration of the resulting coee. Moreover,

caeine concentrations do not demonstrate the same sensitivity to roasting temperatures as 3-CGA, and all coee

roasts and grinds were found to have comparable caeine concentrations at equilibrium, with the exception of the

dark roast - coarse grind coee. e relatively high standard deviations are suspected to be caused by the hetero-

geneous grind size distributions from the commercially sourced beans. As the packaging was handled, settling of

ner particles may have caused inter-sample variability.

pH. Work by Andueza et al.

47

and Gloess et al.

48

both report there is no correlation between pH and perceived

acidity in the avor of coees. However, commercial coee vendors continue to relate acidity to coee taste when

marketing coee to consumers. e pH of coee studied in this work ranged from 5.40 to 5.63. Moon et al.

15

observed a correlation between total CGA concentrations and pH of coee extracts. However, data collected in

this work did not provide enough evidence to support the claim by Moon et al.

15

that coee samples containing

high concentration of 3-CGA tend to have high acidity or low pH.

Comparison of hot brew and cold brew coee. ere is a common marketing message that cold brew

coee is fundamentally dierent than hot brew coee. is may be attributed to acidity and/or caeine concen-

tration

49,50

. is work compared the same water-to-coee ratio using cold brew and hot brew extraction processes

to identify any dierences between the two methods with respect to 3-CGA and caeine concentrations. In the

coee extraction process, Moroney et al.

35

described two dierent extraction mechanisms that function on dier-

ent timescales. e fast extraction from the surface and near-surface matrix happens much more rapidly than the

diusion of compounds through the intragranular pore network to the grain surface. Because the time periods

for hot brew and cold brew are drastically dierent, 6 minutes vs. 1440 minutes respectively, the intragranular

diusion may limit the extractable concentration of soluble coee compounds in the hot brew, as compared to

the cold brew.

3-CGA. In Fig.3, the cold brew extraction of caeine and 3-CGA are shown for each of the four coee samples,

with the hot brew concentrations indicated by horizontal lines. Table2 shows the equilibrium concentrations of

3-CGA for the hot and cold brew coees along with the pH. In both hot and cold brew extractions, all samples

show comparable average 3-CGA concentrations and pH, regardless of water temperature. e CGA molecule is

not seen to be limited by the intragranular pore diusion processes, as observed with caeine extraction. CGA

is freely soluble in water, and this facilitates its extraction at both low and high temperatures. While grain size

did not impact the magnitude of 3-CGA concentrations, roasting temperature of the beans did show a noticeable

eect in both cold and hot experiments. In both hot and cold brew extractions, CGA was found in higher con-

centrations in medium roasts than in darks roasts, supporting the work of Trugo and Macrae

37

that suggests that

higher roasting temperatures decomposes CGA and results in lower extraction concentrations.

Caeine. Coarse grain samples, both medium and dark roast, showed a considerable deviation in caeine

concentrations between hot and cold brew extractions (Table3). In both samples, the cold brew coee was found

to have the higher concentration of caeine. Medium grain samples also showed higher concentrations of caf-

feine in cold brew extraction, however, the dierence was not statistically signicant. is result suggests that

the medium grind blends, in both hot and cold extraction, experienced nearly complete extraction during their

respective steeping times. e hot brew extraction saturated the intra- and intergranular pores and facilitated fast

Figure 2. First-order plot for the extraction of 3-CGA from medium grind - medium roast coee particles at

23.5 °C. R

2

= 0.983.

www.nature.com/scientificreports/

5

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

diusion (6-minute steeping times) of caeine across the solid matrix to generate a bulk liquid phase with nearly

the same concentration of caeine as the cold brew coee generated in 400 minutes. Coarse grain samples, with

their higher relative proportion of particles in the 841 µm range, did not reach similar steady-state concentrations

in both hot and cold brews. e faster, hot water extraction was diusion limited, and likely did not allow the

full extraction of caeine across the larger radius particles. e longer brewing times for the cold brew samples

resulted in greater caeine extraction, allowing time for completion of the rate-limiting mass transfer step in the

extraction process.

Role of Grind Size and Roasting Temp in Cold Brew Coee. Further analysis of the data indicates that

the observed CGA and caeine concentration dierences between medium roast and dark roast are, in general,

substantial. Both CGA and caeine showed higher concentration in medium roast samples. Our data is in sup-

port of the works of Trugo, et al.

37

and Hečimović, et al.

51

, both suggest that higher roasting temperatures decrease

the concentration of CGA and caeine. e only exception is the observed dierence in concentration of caeine

Figure 3. Caeine (▲) and 3-CGA (●) concentration as a function of time for each of the four coee samples.

Horizontal lines represent each coee type’s hot water concentration for caeine and 3-CGA. Error bars

represent the range for each measurement.

Coee Sample

(Roast - Grind)

400 min 1440 min

3-CGA

Concentration (mg/L)

Caeine

Concentration (mg/L) pH

3-CGA

Concentration (mg/L)

Caeine

Concentration (mg/L) pH

Medium - Medium 480 ± 60 1060 ± 60 5.61 ± 0.01 510 ± 20 1180 ± 90 5.54 ± 0.02

Medium - Coarse 490 ± 30 1130 ± 50 5.47 ± 0.01 520 ± 40 1230 ± 60 5.40 ± 0.01

Dark - Medium 380 ± 10 970 ± 60 5.63 ± 0.01 390 ± 10 1080 ± 70 5.53 ± 0.01

Dark - Coarse 330 ± 50 930 ± 40 5.51 ± 0.02 360 ± 20 990 ± 30 5.41 ± 0.02

Table 2. Concentration of 3-CGA and caeine and pH of each cold brew coee sample aer 400 minutes and

1440 minutes of brewing time (Mean ± 95% Condence Interval, n = 6).

Coee Sample

(Roast - Grind)

3-CGA Concentration (mg/L) Caeine Concentration (mg/L) pH

Cold Brew

Method

Hot Brew

Method

Cold Brew

Method

Hot Brew

Method

Cold Brew

Method

Hot Brew

Method

Medium - Medium 510 ± 20 510 ± 30 1180 ± 90 1040 ± 70 5.54 ± 0.02 5.41 ± 0.02

Medium - Coarse 520 ± 40 460 ± 40 1230 ± 60 970 ± 70 5.40 ± 0.01 5.35 ± 0.03

Dark - Medium 390 ± 10 430 ± 30 1080 ± 70 1060 ± 70 5.53 ± 0.01 5.61 ± 0.02

Dark - Coarse 360 ± 20 340 ± 10 990 ± 30 840 ± 10 5.41 ± 0.02 5.48 ± 0.02

Table 3. Comparison of equilibrium 3-CGA and caeine concentrations (aer 1440 min) extracted using cold

and hot brew method along with pH (mean ± 95% Condence Interval, n = 6).

www.nature.com/scientificreports/

6

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

when comparing medium roast – medium grind and dark roast – medium grind samples. Although the medium

roast samples showed higher concentration of caeine than dark roast samples, the observed dierence in con-

centration is insignicant due to large variations in the measurements.

Discussion and Conclusional Remarks

is work establishes that brewing times near 400 minutes are adequate to extract the majority of available caf-

feine and 3-CGA in medium and dark roast beans prepared at medium and coarse grinds. Moreover, coarse

grain samples, both medium and dark roast, showed a substantial increase in caeine concentrations than their

hot brew counterparts. No signicant dierences were seen in CGA concentrations between cold and hot brews.

Furthermore, the pH between cold and hot brews were comparable. is work suggests that any claims made

by coee vendors about the dierence in acidity or taste of cold brew coee is not due to variations in 3-CGA

concentrations. e results of this study validate earlier models proposed by by Moroney et al.

35,45

and Spiro and

Seldwood

52

and extend their ndings into cold brew extraction over long time periods.

Furthermore, our analysis indicates that the grind size does not have signicant impact the observed equilib-

rium concentrations for both CGA and caeine. When comparing samples with the same roasting temperatures,

the observed dierences in concentrations are largely within one standard deviation from another. Mathematical

modeling of coee extraction proposed by Moroney, et al.

35,45

suggested that the diusion of coee from the

intragranular pores to the intergranular pores is the rate limiting process. us, it takes longer for the extraction

process to reach equilibrium as the grind size increases. However, in the cold brew process, the extraction time

frame is on the order of hours instead of seconds. Such long extraction time scales allow for the slow diusion

from intragranular to intergranular pores, so this is not a rate determining process in cold brew methodologies.

We have noted that grind size was not well controlled in this study, as this work used commercially available cof-

fee without any size separation prior to extraction. Future work will dierentiate coee grinds by particle size to

further quantify the role of grind size in cold brew coee. Figure4 shows a graphical representation of a poorly

sorted and a well sorted coee grind. Grind size and grind sorting are both important parameters controlling

inter- and intragranular diusion.

Materials and Methods

Materials. Coee from the Kona region of Hawai’i was sourced from Kona Joe Coee, LLC (Kealakekua, HI).

is single origin Arabica (Kona Typica) coee was obtained roasted and ground from Kona Joe Coee follow-

ing their standard preparation processes. Four coee types were used in this study. Two roasting temperatures,

medium and dark, prepared at two grind sizes, medium and coarse were selected for this work. Both roasting and

grinding were done by Kona Joe Coee. Medium roast beans were roasted at 215 °C to 217 °C, Dark roast beans

were roasted at 223 °C to 225 °C. e beans were ground using a Mahlkönig DK-15 industrial grinder.

Standard stock solutions of 400 mg/L caeine and 3-CGA were made daily and diluted to establish calibration

curves for coee analysis. Both purchased from Sigma Aldrich (Milwaukee, WI). HPLC grade methanol was

obtained from Fisher Scientic (Nazareth, PA). Phosphoric acid (85% wt.) was obtained from Sigma Aldrich

(Milwaukee, WI) and diluted to 2.0 mM concentration using DI water. Filtered municipal tap water used in this

study. Analysis of this water, completed by Penn State University’s Agricultural Analytical Services Laboratory

found the water to have a total hardness of 174 mg/L and a pH of 7.5.

Methods. Particle size distribution. e particle size distributions of each grind were determined according

to ASTM C136/C136M-14 Standard Test Method for Sieve Analysis for Fine and Coarse Aggregates procedure.

Samples of 100.0 g of coee grinds were added to a sieve stack including sieve sizes #20 (0.841 mm mesh opening),

#40 (0.420 mm mesh opening), #100 mesh (0.149 mm mesh opening), and pan, to generate grain size distribu-

tions for each coee used in this study.

Cold brew experiments. e cold brewing process was carried out at room temperature (ranging from 21 °C to

25 °C over the experimental period) adapted from a home-brewing recipe suggested by e New York Times’

Figure 4. e graphical image of sorting eects on pore connectivity in coee matrix beds. Grain size

distribution inuences both the intragranular diusion process, as larger grains have greater diusion distances,

and the intergranular pore network, as poorly sorted grain beds have more tortuous pore networks.

www.nature.com/scientificreports/

7

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

Cooking website

9

. A sample of 35.0 g of coee was placed in 350 mL of carbon-ltered municipal water. e coee

was contained in T-Sac

™

tea lter bag (size 4) and placed in a 32-ounce Mason jar tted with a screw-top lid. e

lter bag was used to reduce grind loss during sampling and ensure grinds remained submerged during steeping.

e coee/water mixture was sampled every 15 minutes for the rst hour, then every 30 minutes until hour 7, and

then once an hour until hour 12, a nal sample was taken at 24 hours. Samples collected aer the rst hour were

diluted (1:4) with DI water and ltered using HT Turyn (Pall) 25 mm diameter, 0.2 μm pore size membranes.

Fresh water was added to replace the volume sampled to maintain constant volume. is introduced a small dilu-

tion eect in the resulting solution. Additionally, even with the closed system, there was inevitably evaporation

over the 24 hour testing period. Coee received from Kona Joe Coee was not processed in any way prior to use,

to best match home-brewing conditions. Data presented are an average of triplicate experiments analyzed in

duplicates (n = 6).

Hot brew experiments. Hot brew extraction was conducted using the same coee to water ratio as was used in

the cold brew method. e water was heated to 98 °C and added to coee grounds in a traditional French press

carafe. e water and grounds were allowed to sit for 6 minutes before the lter was depressed and the coee

decanted. Since additional experiments showed that longer mixing times did not result in additional caeine or

3-CGA extraction, 6-minute extraction times were used for all hot brew experiments. Two samples were taken

from each hot brew and each experiment was performed in triplicate (n = 6).

Caeine and 3-CGA measurement. Caeine and 3-CGA were measured in both standard solutions and coee

extracts using an adapted methodology reported in GL Sciences Technical Note No. 67

53

. An Agilent 1200 Series

high performance liquid chromatography system (HPLC) was tted with a Supelco 5 µm column (15 cm × 4.6 cm)

(Supleco, Bellefonte, PA) run at 40.0 °C with a mobile phase mixture of 75% mobile phase A and 25% mobile phase

B (A: 95% 2.0 mM phosphoric acid and 5% methanol; B: 95% methanol and 5% 2.0 mM phosphoric acid). e

ow rate was 1.0 mL/min with an injection volume of 10.0 µL. Caeine and 3-CGA were detected using a diode

array detector at 280 nm and 325 nm respectively.

pH measurements. e pH of each brewed coee sample was measured with a Mettler Toledo FiveEasy

TM

F20

benchtop pH/mV meter.

Statistical Analysis. Two-tailed t-test and ANOVA were employed for determination of similarities in equilib-

rium concentrations of 3-CGA and caeine with consideration of the roast, grind size, and brewing method. e

output of the statistical analysis is included in the supporting information.

Data Availability. All data generated or analyzed during this study are included in this published article (and its

Supplementary Information les).

References

1. Loeld, E. et al. Coee Drining Is Widespread in the United States, but Usual Intae Varies by ey Demographic and Lifestyle

Factors. J. Nutr. 146, 1762–1768 (2016).

2. Perez, M. Cold Brew Might Save the Coee Maret. Bloomberg Marets (2017). Available at: https://www.bloomberg.com/news/

articles/2017-07-19/hot-sales-of-cold-brew-might-just-be-what-coee-maret-needs. (Accessed: 11th November 2017).

3. Brown, N. New US Coee Shop Growth Slows as TD and Cold Brew Accelerate, According to Mintel. oast Magazine (2017).

Available at: https://dailycoffeenews.com/2017/10/03/new-us-coffee-shop-growth-slows-as-rtd-and-cold-brew-accelerate-

according-to-mintel/. (Accessed: 11th November 2017).

4. Website. Starbucs Cold Brew Coee Available at: http://lp.starbucs.com/coldbrew. (Accessed: 8th May 2017).

5. Starbucs

®

Cold Brew Coee. Available at: http://lp.starbucs.com/coldbrew. (Accessed: 26th July 2017).

6. cold-brew | Dunin’ Donuts. Available at: https://www.dunindonuts.com/en/food-drins/iced-drins/cold-brew. (Accessed: 26th

July 2017).

7. Toddy Instruction Manual and Guide | Toddy Cold Brew. Available at: https://toddycafe.com/cold-brew/instruction-manual.

(Accessed: 26th July 2017).

8. Food. How to Mae Cold-Brewed Coee. Food52 (2017). Available at: https://food52.com/blog/7317-how-to-mae-cold-brewed-

coee. (Accessed: 26th July 2017).

9. Times, T. N. Y. Cold-Brewed Iced Coee ecipe. NYT Cooing Available at: https://cooing.nytimes.com/recipes/1017355-cold-

brewed-iced-coee. (Accessed: 26th July 2017).

10. 1912 Pie.com Story, A. How To Mae Cold Brew Coee at Home. Starbucs Store Available at: http://store.starbucs.com/blog/

how-to-cold-brew-coee-at-home. (Accessed: 26th July 2017).

11. Blumberg, S., Fran, O. & Hofmann, T. Quantitative studies on the influence of the bean roasting parameters and hot water

percolation on the concentrations of bitter compounds in coee brew. J. Agric. Food Chem. 58, 3720–3728 (2010).

12. Blan, I., Sen, A. & Grosch, W. Potent odorants of the roasted powder and brew of Arabica coee. Zeitschri für Lebensmittel-

Untersuchung und -Forschung 195, 239–245 (1992).

13. Sh i b am oto, T. et al. Application of HPLC for evaluation of coee avor quality. In e Quality of Foods and Beverages 311–334

(1981).

14. Bell, L. N., Wetzel, C. . & Grand, A. N. Caeine content in coee as inuenced by grinding and brewing techniques. Food es. Int.

29, 785–789 (1996).

15. Moon, J.-., Yoo, H. S. & Shibamoto, T. ole of roasting conditions in the level of chlorogenic acid content in coffee beans:

correlation with coee acidity. J. Agric. Food Chem. 57, 5365–5369 (2009).

16. Niggeweg, ., Michael, A. J. & Martin, C. Engineering plants with increased levels of the antioxidant chlorogenic acid. Nat.

Biotechnol. 22, 746–754 (2004).

17. Sato, Y. et al. In vitro and in vivo antioxidant properties of chlorogenic acid and caeic acid. Int. J. Pharm. 403, 136–138 (2011).

18. del Castillo, M. D., Ames, J. M. & Gordon, M. H. Eect of roasting on the antioxidant activity of coee brews. J. Agric. Food Chem.

50, 3698–3703 (2002).

19. Chu, Y.-F. Coee: Emerging Health Eects and Disease Prevention. (John Wiley & Sons, 2012).

www.nature.com/scientificreports/

8

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

20. Nordestgaard, A. T. & Nordestgaard, B. G. Coffee intae, cardiovascular disease and all-cause mortality: observational and

Mendelian randomization analyses in 95 000-223 000 individuals. Int. J. Epidemiol. https://doi.org/10.1093/ije/dyw325 (2016).

21. Moghadasian, M. H. & Esin, N. A. M. Functional Foods and Cardiovascular Disease. (CC Press, 2012).

22. ouli, G.-M. et al. J-shaped relationship between habitual coee consumption and 10-year (2002–2012) cardiovascular disease

incidence: the ATTICA study. Eur. J. Nutr (2017).

23. Malerba, S. et al. A meta-analysis of prospective studies of coffee consumption and mortality for all causes, cancers and

cardiovascular diseases. Eur. J. Epidemiol. 28, 527–539 (2013).

24. Preedy, V. . Coee in Health and Disease Prevention. (Academic Press, 2014).

25. Wang, L., Shen, X., Wu, Y. & Zhang, D. Coee and caeine consumption and depression: A meta-analysis of observational studies.

Aust. N. Z. J. Psychiatry 50, 228–242 (2016).

26. Shang, F., Li, X. & Jiang, X. Coee consumption and ris of the metabolic syndrome: A meta-analysis. Diabetes Metab. 42, 80–87

(2016).

27. Chrysant, S. G. e impact of coee consumption on blood pressure, cardiovascular disease and diabetes mellitus. Expert ev.

Cardiovasc. er. 15, 151–156 (2017).

28. Sang, L.-X., Chang, B., Li, X.-H. & Jiang, M. Consumption of coee associated with reduced ris of liver cancer: a meta-analysis.

BMC Gastroenterol. 13, 34 (2013).

29. Li, G., Ma, D., Zhang, Y., Zheng, W. & Wang, P. Coee consumption and ris of colorectal cancer: a meta-analysis of observational

studies. Public Health Nutr. 16, 346–357 (2013).

30. Je, Y. & Giovannucci, E. Coee consumption and ris of endometrial cancer: ndings from a large up-to-date meta-analysis. Int. J.

Cancer 131, 1700–1710 (2012).

31. Bauradze, T. et al. Antioxidant eectiveness of coee extracts and selected constituents in cell-free systems and human colon cell

lines. Mol. Nutr. Food es. 54, 1734–1743 (2010).

32. Navee d, M. et al. Chlorogenic acid (CGA): A pharmacological review and call for further research. Biomed. Pharmacother. 97, 67–74

(2017).

33. L ang, . et al. Quantitative studies on roast inetics for bioactives in coee. J. Agric. Food Chem. 61, 12123–12128 (2013).

34. Spiro, M. & Hunter, J. E. e inetics and mechanism of caeine infusion from coee: e eect of roasting. J. Sci. Food Agric. 36,

871–876 (1985).

35. Moroney, . M., Lee, W. T., O’Brien, S. B. G., Suijver, F. & Marra, J. Coee extraction inetics in a well mixed system. J. Math. Ind. 7

(2016).

36. Spiro, M. & Selwood, . M. e inetics and mechanism of caeine infusion from coee: e eect of particle size. J. Sci. Food Agric.

35, 915–924 (1984).

37. Trugo, L. C. & Macrae, . A study of the eect of roasting on the chlorogenic acid composition of coee using HPLC. Food Chem.

15, 219–227 (1984).

38. Farah, A., de Paulis, T., Trugo, L. C. & Martin, P. . Eect of oasting on the Formation of Chlorogenic Acid Lactones in Coee. J.

Agric. Food Chem. 53, 1505–1513 (2005).

39. Fujioa, . & Shibamoto, T. Chlorogenic acid and caeine contents in various commercial brewed coees. Food Chem. 106, 217–221

(2008).

40. Casal, S., Beatriz Oliveira, M. & Ferreira, M. A. HPLC/diode-array applied to the thermal degradation of trigonelline, nicotinic acid

and caeine in coee. Food Chem. 68, 481–485 (2000).

41. im, A. . & im, J. S. Flavor Contributing Nonvolatile Chemical and Sensory Characterization of Cold Water Extraction-based

Coee by Dierent ExtractionMethods (Dripping vs Steeping) and Time. Journal of e orea Society for Coee Industry 3, 1–9

(2014).

42. Lane, S., Palmer, J., Christie, B., Ehlting, J. & Le, C. Can Cold Brew Coee Be Convenient? A Pilot Study For Caeine Content in

Cold Brew Coee Concentrate Using High Performance Liquid Chromatography. e Arbutus eview 8, 15–23 (2017).

43. Shin, .-S. e Chemical Characteristics and Immune-Modulating Activity of Polysaccharides Isolated from Cold-Brew Coee.

Prev Nutr Food Sci 22, 100–106 (2017).

44. Uman, E. et al. e eect of bean origin and temperature on grinding roasted coee. Sci. ep. 6, 24483 (2016).

45. Moroney, . M., Lee, W. T., O’Brien, S. B. G., Suijver, F. & Marra, J. Modelling of coee extraction during brewing using multiscale

methods: An experimentally validated model. Chem. Eng. Sci. 137, 216–234 (2015).

46. Budavari, S., O’Neil, M., Smith, A., Hecelman, P. & Obenchain, J. e Merc Index, Print Version, Twelh Edition. (CC Press,

1996).

47. Andueza, S., Vila, M. A., de Peña, M. P. & Cid, C. Inuence of coee/water ratio on the nal quality of espresso coee. J. Sci. Food

Agric. 87, 586–592 (2007).

48. Gloess, A. N. et al. Comparison of nine common coee extraction methods: instrumental and sensory analysis. Eur. Food es.

Technol. 236, 607–627 (2013).

49. Calderone, J. Website. Chemistry explains why cold brew coee tastes better than hot (2015). Available at: http://www.businessinsider.

com/cold-brew-coee-taste-chemistry-science-solubles-volatile-2015-8. (Accessed: 26th July 2017).

50. Murray, . Website. What is cold brew coee and why is everyone – including Starbucs – into it? (2015). Available at: http://www.

today.com/food/what-cold-brew-coee-why-everyone-including-starbucs-it-t9481. (Accessed: 26th July 2017).

51. Hečimović, I., Belšča-Cvitanović, A., Horžić, D. & omes, D. Comparative study of polyphenols and caeine in dierent coee

varieties aected by the degree of roasting. Food Chem. 129, 991–1000 (2011).

52. Spiro, M. & Selwood, . M. e inetics and mechanism of caeine infusion from coee: e eect of particle size. J. Sci. Food Agric.

35, 915–924 (1984).

53. Analysis of Chlorogenic Acid in Coee by HPLC. Available at: https://www.glsciences.com/pdf/technicalnote_lc/067.pdf. (Accessed:

26th July 2017).

Acknowledgements

e authors would like to thank Nicolas A. Parenti, Samantha Ryder, Nelly Tchato Setchie, and Maria Latorre

Socas for their contribution in data collection. is work would not have been possible without their oversight of

sample collection, HPLC analysis, and pH measurement. e authors would like to thank the generous funding

support provided by the Eileen Martinson ’86 Fund for the Undergraduate Capstone Experience at the omas

Jeerson University East Falls Campus. e authors would also like to thank Dr. Joseph Alban and Mr. Bruno

Prota at Kona Joe Coee for their insightful suggestions and discussions.

Author Contributions

M.F. contributed to the experimental design, execution. N.Z.R. conceived of the study, aided in experimental

design and execution. M.F. and N.Z.R. contributed equally to all versions of the manuscript.

www.nature.com/scientificreports/

9

Scientific REPORts | (2017) 7:17979 | DOI:10.1038/s41598-017-18247-4

Additional Information

Supplementary information accompanies this paper at https://doi.org/10.1038/s41598-017-18247-4.

Competing Interests: e authors declare that they have no competing interests.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and

institutional aliations.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International

License, which permits use, sharing, adaptation, distribution and reproduction in any medium or

format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Cre-

ative Commons license, and indicate if changes were made. e images or other third party material in this

article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the

material. If material is not included in the article’s Creative Commons license and your intended use is not per-

mitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the

copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

© e Author(s) 2017